Indian Client Visits Our Factory to Explore Masterbatch Solutions for Disposable Tableware

Introduction: In today’s fast-growing disposable tableware market, customer visits are more than just routine inspections. They are a sign of trust, cooperation, and the search for better solutions. Recently, an Indian client specializing in the production of disposable food containers and tableware visited our factory. The focus of the visit was clear: to evaluate our production strength, quality control system, and product lines that could be applied in the manufacturing of disposable food boxes.

Why is this important? India’s food service sector is boom, with takeout culture and single-use packaging demand growing by the day. This trend is pushing manufacturers to explore cost-effective, durable, and safe raw material solutions. Against this backdrop, the client’s trip to our factory marked an important step toward long long-term cooperation.

Factory Tour and On-Site Observations

The visit began with a comprehensive factory tour. Our guests were first introduced to the raw material storage area, where strict sourcing and handling procedures are applied to ensure purity and consistency. They then moved on to the production lines, which include advanced twin-screw extrusion systems designed for high-capacity and high-precision masterbatch production.

The client paid particular attention to the quality inspection laboratory. Here, they observed how our team conducts melt flow index testing, tensile strength measurements, and color dispersion analysis. One of the visitors asked directly: “How do you ensure consistency when orders vary in size and specifications?” The answer came easily. We follow international quality standards and have automated monitoring systems that ensure each batch meets customer specifications.

The tour concluded with a look at our finished goods warehouse and packaging section. The client remarked on the cleanliness and efficiency of the operations. Their impression was that the factory scale, equipment, and quality systems were more advanced than they had expected.

Product Discussion: Focus on Calcium Carbonate, Talc, and Black Masterbatch

Calcium Carbonate Filler Masterbatch: Recognized for reducing raw material costs while maintaining the strength of disposable tableware. This was particularly relevant to the client, as the high consumption volume of food boxes in India demands cost-effective solutions.

Talc Filler Masterbatch: The client showed keen interest in talc fillers for improving heat resistance and surface smoothness of food boxes. With India’s market moving toward higher-quality and more durable disposable products, talc-based solutions present a strong value proposition.

Black Masterbatch: Used for protective or premium packaging applications, black masterbatch was also discussed. The client noted the rising demand for black-colored food trays and box lids in their domestic market.

Both side discuss technical details such as loading percentages, processing stability, and food-contact safety certifications. The client emphasized that while cost efficiency is critical, food safety and compliance with Indian regulatory standards are equally important.

Filler Masterbatch Market Analysis for Disposable Tableware

Why focus on filler masterbatch for disposable food containers? The answer lies in both economics and performance.

The disposable tableware market in India and globally is growing at double-digit rates. Drivers include rapid urbanization, rising middle-class consumption, and the expansion of quick-service restaurants and food delivery services.

Calcium Carbonate Filler Masterbatch is widely used because it allows high filler loading while maintaining adequate strength and brightness. It directly reduces the use of virgin polymers, making products more affordable.

Talc Filler Masterbatch provides added advantages in heat resistance and stiffness, making containers safer for hot food and microwave applications.

Black Masterbatch finds niche applications in high-end disposable tableware, offering both aesthetics and protection from UV light.

The overall market trend is clear: manufacturers want filler masterbatches that are cost-effective, safe for food contact, and adaptable to high-speed production lines. This aligns perfectly with what we provide.

Client Feedback and Recognition

After the tour and discussions, the Indian client expressed positive impressions of both the factory and the product portfolio. They recognized the depth of our quality control measures and appreciated our ability to customize solutions based on their application needs.

“Your filler masterbatch shows good potential for disposable food boxes. If it performs well in trials, it will help us reduce costs and improve product performance at the same time.”

They also highlighted the professionalism of our team, noting how technical questions were answered clearly and supported by data. This gave them confidence in exploring further cooperation.

Our Factory Advantages

Our factory’s strengths go beyond size and equipment. With more than 10 years of experience in masterbatch production, we have built a reputation for stability and innovation. Advanced extrusion lines, automated testing, and a dedicated R&D team ensure we can meet the requirements of different industries, including food packaging, construction, and consumer goods.

Strict quality control procedures are applied at every stage, from raw material selection to final product inspection. This not only ensures compliance with international standards but also gives customers peace of mind that they are receiving reliable, consistent products. In addition, our large-scale production capacity allows us to respond quickly to large orders while keeping prices competitive.

Product Series Overview

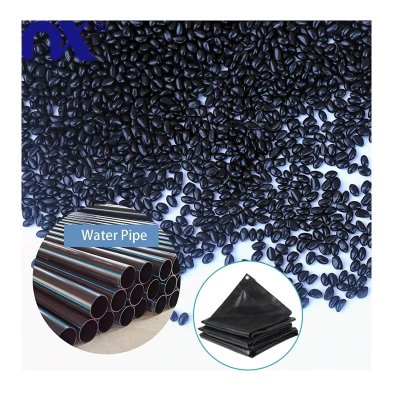

Black Masterbatch for pipes, films, cables, and packaging

White Masterbatch for food-grade and high-opacity applications

Color Masterbatch for aesthetic and branding purposes

Calcium Carbonate and Talc Filler Masterbatch for cost reduction and performance improvements

Desiccant Masterbatch for recycled plastics with high moisture content

Plastic Bags for packaging and retail applications

By offering such a more range, we provide customers with one-stop solutions that improve efficiency and simplify supply chain management.

Cooperation Plans and Next Steps

The immediate plan is to send sample batches of calcium carbonate filler, talc filler, and black masterbatch for the client to test in disposable food box production. These trials will focus on transparency, heat resistance, rigidity, and food-contact safety.

If successful, the client intends to place larger orders and integrate our products into their production lines. Technical support, including on- site guidance and process optimization, will be provided to ensure smooth adoption.

Looking further, the client expressed interest in long-term cooperation, including potential distributor partnerships in India. This would allow both parties to strengthen their positions in one of the world’s fastest-growing packaging markets.

Market Outlook: India and Beyond

The Indian market for disposable tableware is expanding rapidly, driven by the food delivery boom and consumer preference for convenient packaging. Will this trend slow down? The answer is unlikely. With population growth and urban lifestyle changes, demand is expected to remain strong.

Globally, the shift toward more sustainable and cost efficient materials also supports the use of fillerMB. By replacing a portion of virgin polymers with fillers like calcium carbonate and talc, manufacturers can cut costs and reduce environmental impact.

Our factory is well positioned to serve this demand, not only in India but also in other regions such as Africa, Southeast Asia, and the MiddleEast.

Conclusion

The visit of the Indian client to our factory marks a milestone in building stronger cooperation in the disposable tableware industry. From the detailed factory tour to the in-depth product discussions, the visit demonstrated mutual trust and shared goals.

Our calcium carbonate, talc, and black masterbatches have shown clear advantages for disposable food box applications. With the upcoming trials, we are confident that our solutions will help the client achieve cost savings, performance improvements, and compliance with food safety requirements.

As one of the leading suppliers of filler and color masterbatch solutions, we remain committed to working with global partners to create value and promote innovation. After all, who said industrial cooperation can’t be both professional and inspiring?