Blue Masterbatch for Mobile Phone Case

Bright, stable blue shade across long runs.

Clean dispersion and smooth surfaces.

Good flow in thin walls and small gates.

Less streaking and fewer specks.

Fast to match, easy to repeat.

Flexible carriers for common case resins.

Overview

Phone cases seem simple. They are not. The market wants shine, smooth touch, and stable color. People also want scratch resistance. The case must survive heat, sun, and daily use. Our Blue Masterbatch helps you hit that target. It gives a strong, steady blue. It runs clean in injection machines. It spreads well. The surface looks neat and bright.

This is a true color masterbatch. It blends quality pigments with a clean carrier. It fits common resins used in cases. You can use PP, PE, ABS, or EVA. It flows well in thin walls. It holds shade in long runs. It supports glossy or matte tools. It works in fast cycles. It also works in slow lines. You choose the speed. The blue stays steady.

We build the shade with care. We check color from batch to batch. We use tight control on pigment loading. We run checks on melt index. We test heat resistance. We test light aging. We inspect each lot. Your team gets color that stays. Your customers see the same tone across all units. No surprises. No random shifts.

The result is simple. Fewer rejects. Less clean-up. Lower scrap. Smoother runs. A case that looks premium on day one and still looks good months later.

Why Blue Masterbatch for Phone Cases?

People hold their phones all day. The case takes the hit. Color must last. The finish must look clean. Our Blue Masterbatch answers that need. It offers stable shade and good dispersion. It controls streaks and spots. It helps keep a smooth skin and a solid tone.

Stable shade: The color stays true in long runs and repeat orders.

Strong dispersion: Pigments spread well. You see fewer lines and fewer specks.

Smooth flow: It fills thin ribs and tight corners with less stress.

Heat and UV support: Helps cases hold color in day-to-day sun and heat.

Low odor, low VOC: Better for teams and end users.

Flexible carrier: PP/PE/EVA options. ABS support via tailored grades.

It is still a color masterbatch. So your team can dose it with precision. You can hit your shade target with less effort. You can keep the same tool and process. No extra drying gear is needed for the masterbatch itself. It blends right in. You just feed and run.

Product Parameters

| Product Name | Blue Masterbatch for Mobile Phone Case |

|---|---|

| Category | Color masterbatch (blue shade, case grade) |

| Carrier Options | PP / PE / EVA (ABS-supporting grade available on request) |

| Melt Index (MI) | 10–30 g/10 min (230°C/2.16 kg), grade-dependent |

| Recommended Dosage | 2%–5% typical for glossy cases; adjust to shade and resin |

| Heat Resistance | Process-ready for common case temps; consult for PC/ABS blends |

| Light Fastness | Optimized for indoor/outdoor daily use; UV packages available |

| Moisture | ≤0.3% (typical at pack); keep sealed |

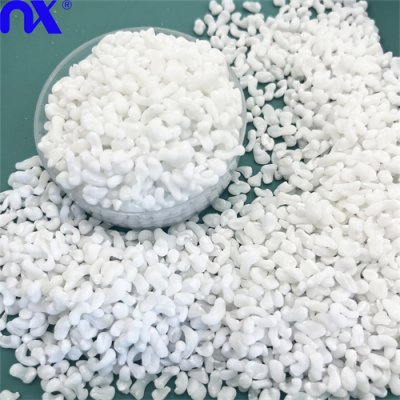

| Appearance | Uniform blue pellets, low dust, clean cut |

| Compatibility | PE, PP, PVC, HIPS, ABS (project-specific tuning offered) |

| Package | 25 kg bag (paper/plastic composite + PE inner liner) |

| Storage | Cool and dry; use FIFO; seal after opening |

Applications

Our Blue Masterbatch focuses on mobile phone cases. It also works well in other devices. You can use it in small consumer goods. You can use it in wearables. You can use it in home devices. The shade stays bright. The surface looks crisp. The flow stays smooth.

Phone Cases

Great for slim shells and protective frames. It fills thin walls with ease. It helps keep a neat gate mark. It supports glossy skins. It also supports soft-touch paint lines that go on top. The color holds under daily heat from the device and the hand.

Small Electronics

Use it for wireless earbud cases, chargers, and hubs. The blue shade looks fresh and clean. It works well with logo pads. It works with tight snaps. It runs in simple tools or complex tools. It supports long mold life with less build-up.

Accessory Parts

Try bands, clips, stands, and car mounts. The color stays even on curved shapes. It fits extrusion for simple profiles. It fits injection for complex shapes. It gives a uniform skin that looks premium.

Processing Guidance

Good results start with simple steps. Keep resins dry. Keep the masterbatch sealed until use. Load with a gravimetric or volumetric feeder. Mix well in the hopper. Purge lines before a shade change. Keep temps aligned with your base resin. You should not need a large shift in settings.

Dosage: Start at 3%. Move up or down to hit the shade target.

Mix: Pre-blend at the hopper. Short tumble mix is enough in most cases.

Tooling: Clean gates and vents. It helps with high gloss skins.

Cycle: Keep fill time stable. Avoid big back pressure swings.

Cooling: Use steady cooling for flat, clean skins.

If you face knit lines, raise back pressure a little. If you see flow marks, check melt temp and injection speed. If you chase gloss, try a small rise in mold temp. Our team can help. Share your part wall and flow length. We can suggest a path in a few minutes.

Color and Quality Control

Color must be consistent. We track lots with tight limits. We measure L*a*b*. We lock shade windows. We run tests on dispersion. We check melt flow. We keep retains. We can match your standard and ship a hold sample with the first batch. You get the same look in future runs.

Color match to Pantone / RAL or your chip.

ΔE targets as tight as your brand needs.

Batch-to-batch shade control and retain policy.

Optional UV packages for outdoor retail stands.

RoHS and FDA options where needed.

About Nuoxin

We are a masterbatch maker with a simple promise. Give stable shade. Keep lines smooth. Help brands look sharp. Our team runs modern lines. We build color masterbatch for many markets. We support packaging, electronics, and daily goods. We ship fast. We keep quality tight.

Our lab has color measurement tools. We test heat and light. We track lot data. We keep your color safe in our system. You can reorder with confidence. We will hold the tone and the flow profile. We stand behind every batch.

Packing and Delivery

We pack in 25 kg bags with an inner PE liner. Bags sit on stretch-wrapped pallets. Keep bags sealed until use. Store in a cool and dry place. For samples, we use express. For full orders, we can ship by sea, air, or truck. Lead time is short. We can move fast for repeat shades.

Sample: express courier.

Bulk: sea or ground freight, as you need.

Docs: TDS, MSDS on request.

FAQ

1) What sets this Blue Masterbatch apart?

It is built for cases. It targets thin walls and smooth skins. It holds shade. It runs clean. It keeps your cycle stable.

2) Can you match our brand blue?

Yes. Send a Pantone, RAL, or a chip. We will match and confirm with a small run. We can hold that tone for future lots.

3) What dosage should I start with?

Start at 3%. Adjust by test shots. Raise for deeper tone. Lower if you chase a lighter look.

4) Will this work with ABS or PC/ABS?

We can tailor a grade for ABS and PC/ABS. Share your melt and mold temps. We will suggest the right package.

5) Do you support food-contact?

For cases, it is not common. But we have food-contact options for other goods. Ask our team for details.

6) What about UV?

We can include a UV package. It helps outdoor kiosks or window displays. It also helps cases in strong light markets.