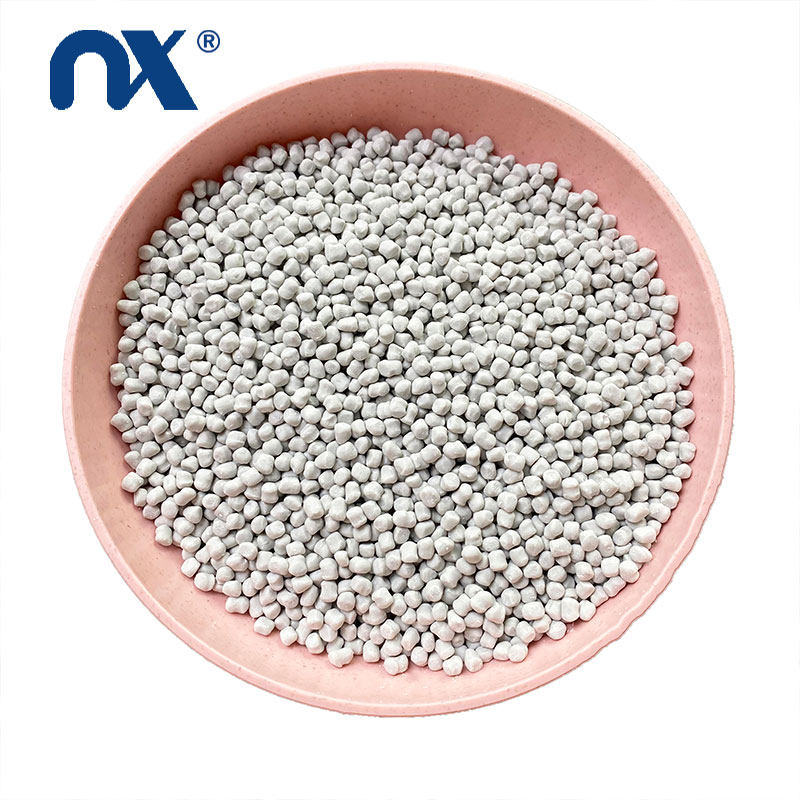

talc filler masterbatch

1. Excellent Dispersion

Smooth mixing, no clumps. Better production, fewer defects.

2. Good Color & Gloss

Improves product look and brightness. Reduces need for extra colorants.

3. Higher Stiffness & Hardness

Makes parts more rigid and resistant to bending.

4. Better Strength & Tear Resistance

Ideal for films and straps. Improves pulling and tearing strength.

Product Introduction

Our talc masterbatch is made from premium grade lamellar talc powder. It goes through strict surface treatment. Then it is blended with high-quality carrier resin by twin-screw extrusion. The final product is stable and easy to process. Many customers use it in polypropylene (PP) and polyethylene (PE) modification. It improves rigidity, heat resistance, dimensional stability, and surface gloss. At the same time, it reduces costs because talc is much cheaper than resin. This balance between performance and cost makes it a smart choice for manufacturers.

Talc master batch is often used by factories that want stable production. It helps reduce shrinkage and warpage. It also improves the look and feel of products. Because of these features, more industries are switching to talc filler masterbatch. The adoption rate is growing fast in Asia, Europe, and North America.

Product Parameters

| Item | Parameter |

|---|---|

| Product Model | TALC-MB50 (customizable) |

| Appearance | White uniform cylindrical pellets |

| Carrier Resin | PP/PE (customizable) |

| Talc Content | 50%, 60%, 70%, 80% |

| Moisture Content | ≤ 0.3% |

| MFI | 2-10 g/10min (190°C, 2.16kg) |

| Density | 1.5 - 2.0 g/cm³ |

Product Features

Cost reduction with high filling ratio up to 80%.

Improved rigidity and tensile strength.

Better heat resistance for high-temperature use.

Good dimensional stability and reduced shrinkage.

Smoother surface and better product feel.

Good dispersion and easy processing, no dust pollution.

Environmentally safe and non-toxic, FDA,RoHS compliant.

Product Applications

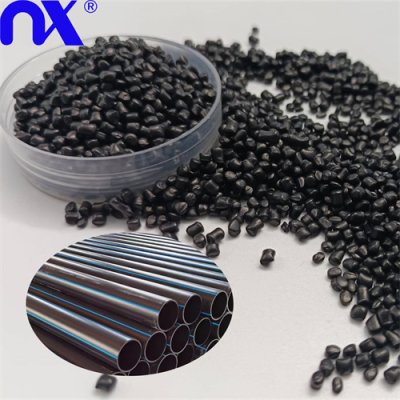

Talc filler masterbatch is widely used in the automotive sector. It strengthens parts like bumpers, dashboards, fan covers, and trays. For home appliances, it is applied in washing machine drums, air conditioner shells, and small device housings. In daily products, it is used for furniture, boxes, chairs, and tables. In packaging, talc master batch works well in PP straps, stretch films, and blow molded containers. In industrial parts, it helps in pipes, fittings, and pallets.

Customers also choose masterbatch talc for films and sheets. It makes them tougher and less likely to tear. In injection molding, it reduces defects and makes products more stable in shape. In extrusion, it gives better flow and avoids blocking. These advantages make talc master batch a popular additive in multiple industries.

Customer Application Case

A customer from Canada once purchased talc filler masterbatch from another supplier. They used it to produce Disposable lunch boxes. The boxes were too soft and failed to meet strength requirements. Later, they tried our talc masterbatch. The result was much better. The containers became rigid, strong, and stable. The customer confirmed that the hardness now met their production standard. They decided to switch fully to our master batch talc. Since then, their complaints from end users have decreased. This case shows how performance improves when you choose the right material.

Factory Direct Supply

We are not traders. We own a modern production base. Our prices are competitive because there is no middleman. We maintain large stock of regular models and can deliver quickly. Our team supports customization of talc content, resin type, and particle size. We respond fast to customer questions and provide technical help.

Over 10 Years of Expertise in Plastic Masterbatch Production

Nuoxin Factory has over a decade of experience in the production of plastic masterbatches, specializing in R&D and manufacturing. We have accumulated rich industry knowledge and technical expertise.

High Standards and Quality Certifications

We have passed ISO9001 quality management certification, and our products comply with FDA, ROHS, MSDS, TDS, and other international standards.

Strategic Location and Well-Equipped Production Base

Located in Shandong Province, China, our factory covers 40,000 square meters, with convenient transportation and complete infrastructure, ensuring fast delivery and short lead times.

Packaging and Delivery

Standard packing is 25kg per bag. The outer layer is PP woven, and the inner is PE liner. Each pallet can hold 40 to 48 bags, around one ton. The goods are wrapped in film for safe transport. We have enough stock for regular models. We cooperate with trusted logistics companies. Global shipping is available. Delivery is fast, safe, and reliable.

Free Sample Testing

We provide free samples for customers. Before purchase, you can test our product in your own formula and machines. Many clients use this option. They find the results reliable and close to production conditions. Once they see the benefit, they place larger orders. This way, both sides build trust. We encourage new buyers to try samples before making decisions.

Other Product Recommendations

Besides talc master batch, we also supply calcium carbonate masterbatch. It is cost-effective for general use. We provide barium sulfate masterbatch. It gives higher density and glossy surface. We produce glass fiber reinforced masterbatch. It boosts strength and heat resistance. For non-woven fabric, we supply special additives like electret and antibacterial masterbatch. These products give customers a full range of solutions. You can get all from one reliable source.

Extended Discussion: Why Choose Talc Masterbatch

Many producers compare talc filler masterbatch with calcium carbonate. Both are useful, but talc gives better heat resistance and surface smoothness. It is chosen when product looks and stability matter. A film producer in Southeast Asia switched from calcium carbonate to talc master batch. They noticed fewer film breaks, smoother rolls, and stronger bags. They shared positive feedback after a few months of testing.

Talc filler masterbatch also fits companies seeking eco-friendly options. It reduces resin use, which lowers carbon footprint. It also helps in recycling since talc is stable and safe. As sustainability becomes important, more manufacturers adopt talc-based solutions. Demand is increasing not only in packaging but also in automotive and household industries.

Another strong point is processing speed. Many factories report faster extrusion lines when using our master batch talc. The pellets melt smoothly and disperse well. There is less filter blocking. This means less downtime and higher production efficiency. With stable supply, we support factories in running continuous operations without quality risk.

11. Conclusion

Talc masterbatch is more than just a filler. It is a solution to improve product strength, reduce cost, and enhance appearance. With our reliable supply and technical support, customers gain long-term value. Whether you are making containers, films, parts, or furniture, masterbatch talc can support your success. Contact us today for details, samples, and orders. Let us help your factory grow with stable and high-performance solutions.