Masterbatch for Pvc Panels

This black masterbatch has notable advantages in plastic processing. It’s highly compatible with PP/PE, working stably in injection molding and film blowing. It meets strict demands like melt flow and molding precision in injection, and film uniformity and mechanical properties in blowing, reducing colorant replacement costs.

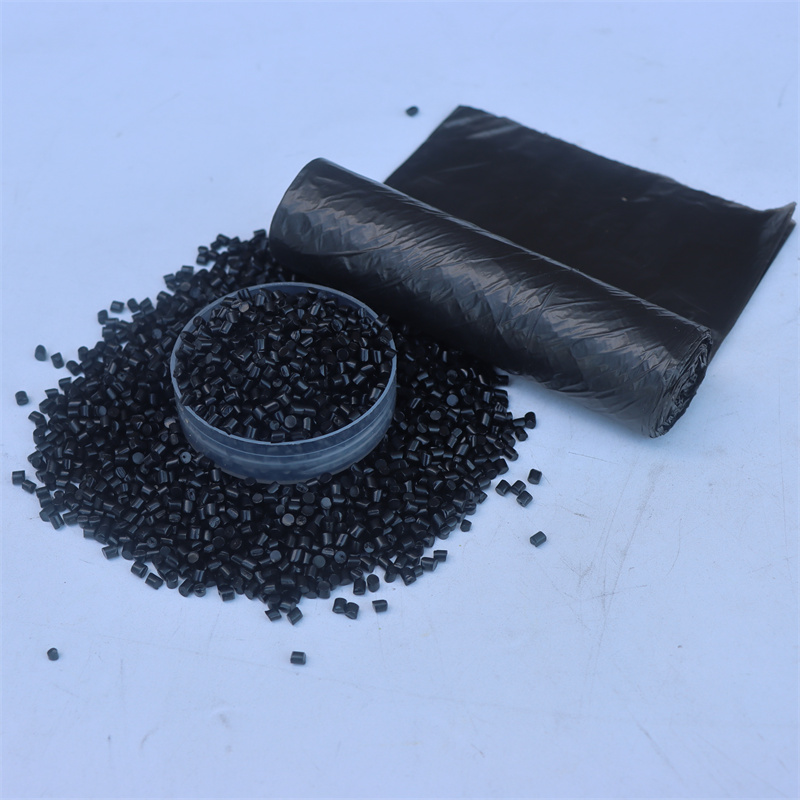

black masterbatch applications are wide: making lunch boxes with safe, uniform coloring; enhancing geomembranes/geotextiles’ UV resistance and ease of use; improving aquatic/ordinary plastic bags’photophobism and durability.

With a 2%-5% addition ratio, it cuts raw material costs, avoids harming plastic’s mechanical properties, and simplifies proportion control for consistent coloring.

Boasting 100 tons daily output and fast delivery, it meets large orders, shortens lead times, aids production planning, and suits time-sensitive orders, supporting market competitiveness.

Product Description

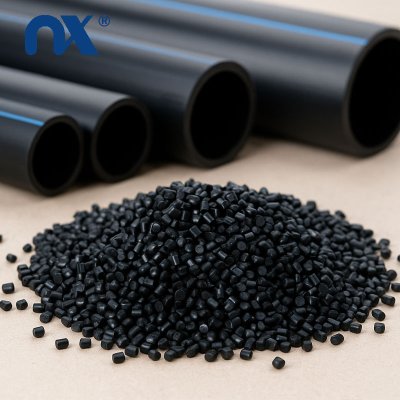

Black masterbatch, a masterbatch made primarily from carbon black, combined with a resin carrier and dispersing agents through injection molding, extrusion, and other processes, is primarily used for coloring plastic products. It appears as cylindrical pellets (2.2 x 2.8 mm). Heat resistance varies depending on the carrier resin, for example, PVC/PE can withstand temperatures of 160-180°C, while PP/PA can reach temperatures above 280°C. This material offers high blackness, high gloss, and easy dispersion, reducing color spots and streaks. The production process is pollution-free and meets environmental standards.

With the development of the plastics industry, black masterbatch production processes have been continuously optimized, forming a system centered around carbon black pre-dispersion technology. This solves the challenges of traditional carbon black flotation and uneven coloring. Carrier materials have expanded from general-purpose PE and PP to specialized resins such as ABS, PC, and PA, enabling adaptability to diverse applications. Applications extend from basic plastics processing to high-end manufacturing applications such as automotive parts, electronic devices, and geotechnical materials, and have also led to the development of functional products such as conductive and flame-retardant materials. Current technical focus is on improving weather resistance and degradation-resistant environmental performance.

Application

Black masterbatch is a crucial functional additive in agricultural films (such as greenhouse films and ground films). Its core function is to impart specific properties to the films through the evenly dispersed black pigment (primarily carbon black), thereby meeting various agricultural production requirements.

Key Functions of Agricultural Films:

1. Shading and Controlling Light, Suppressing Weed Growth

Ground Film Applications: Black ground films are virtually opaque. Their transmittance is typically less than 5%. They are applied to the soil surface. They block sunlight. This prevents weed seeds from photosynthesizing. It inhibits weed growth. It reduces manual weeding. It reduces pesticide use. It lowers agricultural production costs.

Auxiliary Applications for Greenhouse Films: Some specialized greenhouse films are available. Examples include shade net replacement films. They contain black masterbatch. They adjust the light shading ratio. The ratio is typically 30%-70%. This creates a suitable light environment. It is for shade-loving crops. Examples are edible fungi and lettuce. It also prevents strong sunlight from burning them.

2. It regulates soil temperature. It retains moisture. Black mulch absorbs more solar heat. It raises soil temperature. This is especially true in cold weather. The temperature can rise by 2-5°C. This promotes root development. It also promotes seed germination.

What's more, shading reduces soil evaporation. It conserves moisture. So it is suitable for arid and semi-arid regions.

Summer temperatures can be high. At such times, black mulch can be combined with a reflective layer. Or it can have an appropriately designed thickness. Then it can reduce soil heat absorption. This prevents excessive warming. It protects crop roots from heat damage.

3. Improves the soil microenvironment and reduces pests and diseases. Shading reduces soil surface moisture fluctuations, reducing diseases caused by high temperature and humidity (such as powdery mildew and downy mildew). Furthermore, reducing weeds indirectly cuts off pest food sources and habitats, reducing pest and disease incidence. Some black masterbatches are compounded with functional ingredients such as antimicrobials to further enhance the mulch's pest and disease control capabilities.

4. Extending the Lifespan of Films (Anti-Aging)

Carbon black possesses excellent UV shielding properties. It absorbs and converts UV energy, reducing the degradation of film substrates (such as PE) by UV rays, delaying film aging and embrittlement, and extending the lifespan of agricultural films.

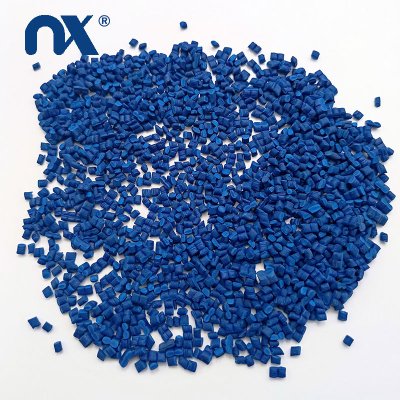

Other Masterbatch

Masterbatch is our advantage product. Of course, in addition to black masterbatch, we also have Color Masterbatch and any color of color masterbatch can be customized. Desiccant masterbatch eliminates moisture in plastic products and reduces the cost of drying. Filling masterbatch is divided into sodium sulfate filling masterbatch and calcium carbonate filling masterbatch. Without changing the physical properties and color of the product, it can greatly reduce the production cost.

FQA

Q1:Are you factory?

A: Third Party Inspection is available, also we are ISO, CE, Alibaba Verified. Furthermore mill Test Certification is available with shipment. Our quality management system conforms to the requirement of ISO 9001:2015 verified by TUV. We accept trial order to enhance mutual trust.

Q3: Why choose us?

A: We are factory direct supplier, with competitive quality and price, and also brilliant services.

Q4. To which countries have you already exported?

A: For more than 30 countries such as Belgium, Brazil, France, Germany, India, Korea, Kuwait, Peru, Qatar, Romania, South Africa,Spain, Sri Lanka, Sudan, Thailand, Tobago, Vietnam, UAE, UK, Ukraine, USA, etc.

Q5: Any free sample available?

A: Sure! Our regular sized samples are free but buyers have to pay for shipping.

Q6: How can I get more details about your products?

A: You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.

Q7: Do you provide customized parts?

A:Yes, we accept drawings from customers to manufacture accordingly.