Color Masterbatch in Injection Molding: Boosting Appearance, Performance, and Market Competitiveness

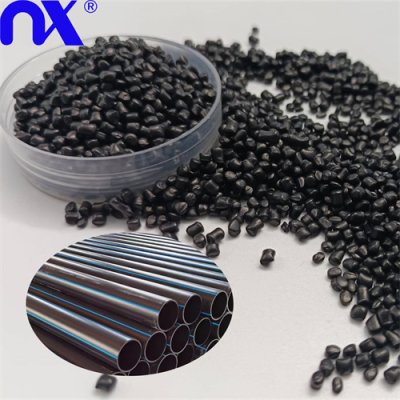

Some plastics look very textured and have bright colors, but some plastics look cheap because they give people a feeling that they are not clean. Do you know why?? A product's appearance influences perception, quality judgment, and buying decisions. In plastics manufacturing, achieving consistent and vibrant colors is crucial. Color master batch is one of the best ways to ensure this. It mixes pigments, carrier resin, and additives, creating uniform, high-quality coloration every time.

Why Masterbatch is Important

MB protects pigments from air and moisture, maintaining chemical stability. Without it, pigments might absorb water or oxidize, leading to uneven color and defects. The carrier resin is chosen to match the target polymer, such as PE, PP, PVC, PS, or ABS. This compatibility ensures smooth dispersion and reduces sticking during mixing. From my perspective, masterbatch is not just an additive—it is a quality tool that elevates the entire product.

How Master Batch Works in Injection Molding

MB acts as a concentrated pigment. When added to plastic pellets, it melts and disperses uniformly. This ensures bright, consistent colors across all products. It also improves melt flow, reduces streaks, and prevents spots. I have noticed in factories that even minor difference in color can drastically affect consumer perception. Masterbatch helps standardize product appearance.

Applications and Use Cases

Plastic packaging: bags and containers, and films benefit from uniform coloring.

Consumer goods: toys, kitchenware, and electronics achieve a premium look.

Automotive parts: dashboards, trims, and covers require precise color matching.

Medical devices: consistent color helps with brand recognition and quality assurance.

Custom branding: companies can produce unique colors for marketing campaigns.

Custom colors allow brands to stand out in the market and adapt to trends quickly. I personally see this as a game-changer for smaller manufacturers competing with larger brands.

Storage Tips for Longevity

Masterbatch should be stored in cool, dry conditions, away from sunlight and moisture. Heat or humidity can degrade pigments and carrier resins. Proper storage ensures consistent color quality, prevents processing issues, and extends shelf life.

Common Challenges and Solutions

Non-Melting or Color Spots

Sometimes, masterbatch may not melt correctly, causing spots. Causes include mismatch of melt index with base resin or too short molding time. Solutions: improve melt flow, allow sufficient plasticization time, and remove impurities before production.

Color Differences Between Batches

Different batches may show slight variations due to raw material changes or static during mixing. To prevent this: use consistent raw materials, control mixing time, and choose a trusted supplier. Regular testing and equipment checks also help.

Color Streaks

Streaks happen when pigments are unevenly dispersed. Causes: poor mixing, incompatibility with resin, or uneven melt flow. Solutions include optimizing mixing, adjusting temperature and screw speed, and testing pigment-resin compatibility.

Product Breakage

Breakage may occur if masterbatch is overloaded or poorly dispersed. Follow guidelines, use proper mixing techniques, adjust temperature and pressure, and test each batch before full production.

Cost Considerations

Does masterbatch increase costs? Sometimes yes, but it can also save money. By combining inexpensive pigments, manufacturers can achieve the look of pricier pigments. Consistent color reduces waste from trial-and-error. Higher-quality appearance can justify higher selling prices. In my experience, this is an investment that pays off in the long term.

My Observations and Industry Insight

I have seen smaller factories switch to high-quality masterbatch and immediately notice improvements in product consistency. Products look professional, customers are satisfied, and returns decrease. Even minor color improvements enhance market perception. Masterbatch allows creative flexibility. Factories can experiment with seasonal or promotional colors without major changes to production. It supports both quality improvement and innovation. For me, masterbatch is more than an additive—it’s a bridge between manufacturing efficiency, aesthetics, and business growth.

Technical Insights

Using masterbatch requires attention to detail. Factors such as melt index, carrier resin type, pigment compatibility, and processing temperature all influence the final result. Even storage conditions can affect color stability. Consistent product quality requires a rigorous quality control process. We perform batch testing, equipment calibration, and blending checks to ensure consistent quality from batch to batch.

Environmental and Market Considerations

The plastics industry is increasingly conscious of sustainability. Masterbatch can support recycled resin usage by enabling bright, uniform color even in post-consumer plastics. This reduces the need for virgin materials while maintaining product quality. Companies adopting masterbatch technology can market eco-friendly products without sacrificing aesthetics.

Advanced Applications

Blow molding: consistent color in bottles and containers.

Injection molding: toys, automotive, household items.

Extrusion: sheets, films, pipes.

Co-extrusion: multilayer packaging requiring uniform color in each layer.

Custom compound formulations: blending multiple pigments for unique shades.

My personal view is that versatility in application makes masterbatch indispensable. It adapts to both traditional and innovative production techniques.

Case Examples

Consider a manufacturer producing colorful kitchen containers. Switching to masterbatch reduced streaking and spots by 80%, improved consistency, and allowed for faster production. Another company producing toys achieved new vibrant colors that enhanced market appeal. Masterbatch not only improved aesthetics but also reduced customer complaints and returns.

Conclusion

Color master batch is a critical component in injection molding and plastics production. It ensures consistent color, protects pigments, improves processing, supports recycled materials, and enhances product appeal. Proper storage, processing, and quality control are essential. While costs may increase slightly, benefits in aesthetics, consistency, sustainability, and profitability outweigh them. Manufacturers seeking better product performance and market competitiveness should consider high-quality masterbatch. Small steps in pigment management can make a big difference.

In short, masterbatch combines technical innovation, business strategy, and aesthetic appeal. For per plastic manufacturer aiming to improve both product quality and consumer perception, it is a practical, cost-effective, and essential solution.