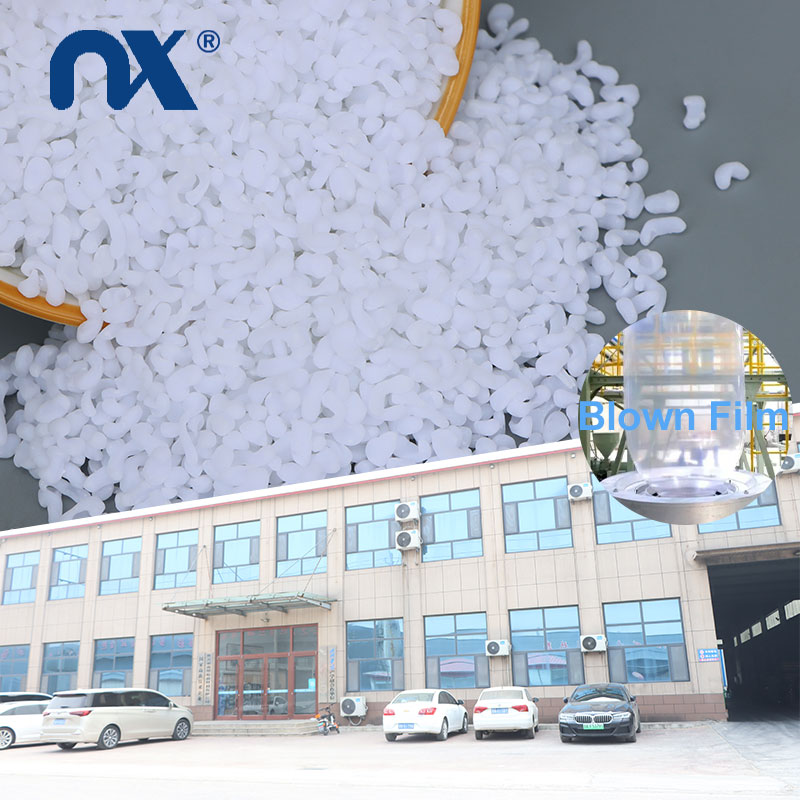

Filler Masterbatch

Advantages:

Increased rigidity: ideal for products that require a stronger structure, such as plastic films, sheets and molded parts.

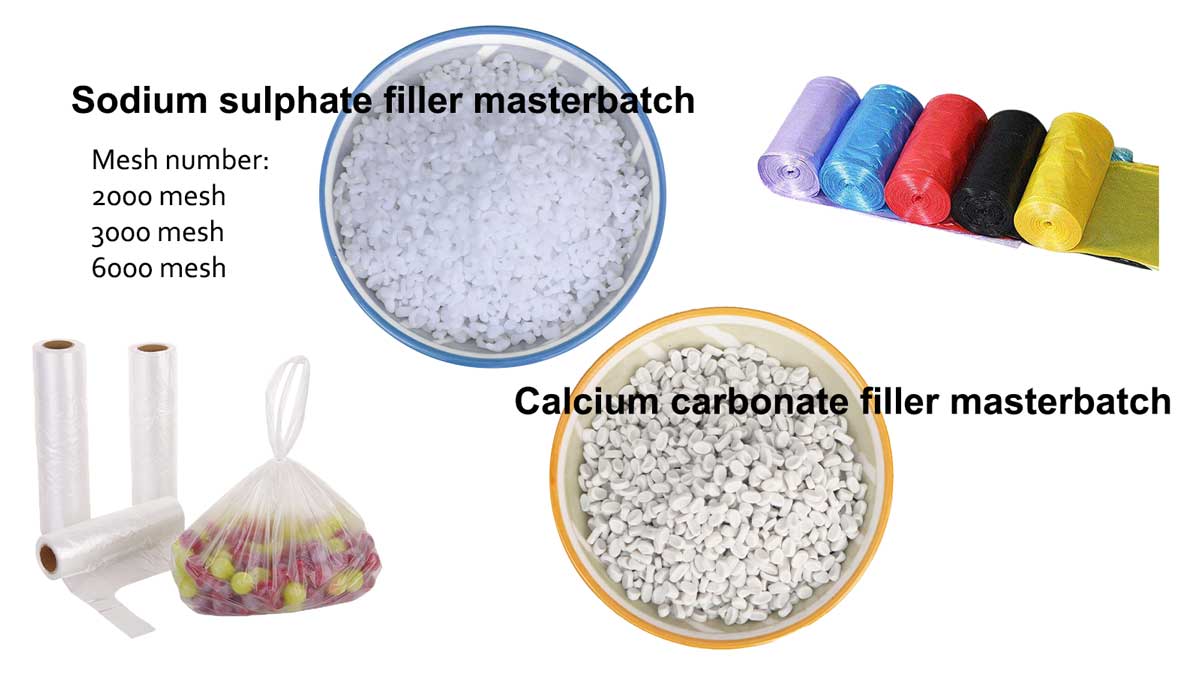

Opacity: Improve the opacity of plastic products, which is particularly important in packaging and film applications. In addition, transparent grade sodium sulfate filler masterbatch has little effect on the transparency of the product. The appropriate amount of addition can not only not affect the product quality but also reduce costs.

Reduce shrinkage: Helps to control shrinkage during cooling, thereby improving product quality.

Improve surface finish: The added filler can improve the surface smoothness of plastic products and enhance their beauty.

Product Description

Filler masterbatch is a high-performance additive used in the plastics industry to reduce material costs while improving the mechanical properties of plastic products. Filler masterbatch is a combination of inorganic fillers such as calcium carbonate (CaCO₃), talc or sodium sulfate (Na₂SO₄) and compatible carrier resins, which can effectively improve the properties of plastic materials without compromising performance.

Key Features

Economical and efficient: significantly reduces the need for expensive raw materials, reducing overall production costs while maintaining product quality.

Enhanced material properties: increases stiffness, improves opacity and enhances the surface finish of plastic products.

Improved processability: optimizes easy dispersion during processing, improving extrusion, injection molding and other plastic manufacturing technologies.

Environmental protection: helps reduce environmental impact by optimizing material use and reducing dependence on raw materials.

High compatibility: suitable for a variety of polymers, including polyethylene (PE), polypropylene (PP), PVC, etc., making it suitable for a variety of applications.

Application

Packaging: Filler masterbatch is widely used in the production of plastic films, plastic bags and plastic containers.

Injection molding: It is very suitable for manufacturing hard, cost-effective plastic products such as household goods, automotive parts and industrial components.

Pipes and profiles: Suitable for pipes and sheets, providing greater rigidity and smooth, professional surface treatment.

Blow molding: Used to make bottles, containers and other hollow products, increase wall thickness and reduce production costs.

Non-woven fabrics: Improve the bulk density and opacity of spunbond and meltblown fabrics, making them suitable for a wide range of industrial applications.

Why choose our filler masterbatch?

Stable quality: Our filler masterbatch is manufactured under strict quality control measures to ensure stable product performance.

Customizable: We offer custom formulations to meet your specific application requirements, providing you with the best solution for your production needs.

Global Supply: Our filler masterbatches are trusted by manufacturers around the world and can be exported to a wide range of international markets.

Whether you want to reduce production costs, enhance the physical properties of your product or improve process efficiency, filler masterbatches are ideal for a wide range of applications in the plastics industry.