What are fillers? Understanding Plastic Fillers: Types, Benefits, and Applications

1. What Are Plastic Fillers?

Plastic fillers are fine particles or powders added during plastic compounding, pelletizing, or molding. They can be derived from minerals, plants, or industrial by-products. Though small and seemingly insignificant, they can greatly influence the behavior and properties of plastics.

Two Main Purposes of Fillers

Cost Reduction

Plastic resins can be expensive and volatile in price. By partially replacing resin with fillers, manufacturers can stabilize and control production costs. For high-volume production, fillers are nearly indispensable.

Performance Enhancement

Different fillers provide various performance benefits, such as:

Increased stiffness and tensile modulus

Improved heat resistance and thermal deformation

Enhanced surface gloss or color performance

Increased transparency (e.g., sodium sulfate)

Better dimensional stability

Improved flow and cooling behavior during processing

Thus, the true value of fillers lies in optimization, not merely “filling space.”

2. Classification of Plastic Fillers

There is a wide variety of plastic fillers, but they are generally classified into two main types based on their origin: inorganic and organic fillers.

1. Inorganic Fillers

Inorganic fillers dominate the market and include:

Calcium Carbonate (CaCO₃)

Talc

Barium Sulfate, Sodium Sulfate

Kaolin, Bentonite

Calcium Silicate, Mica

Quartz, Glass Powder, etc.

Advantages: Low cost, stable supply, chemically stable, good compatibility with resin, and excellent processing performance. Widely used in films, injection molding, extrusion, blow molding, and sheet production.

2. Organic Fillers

Organic fillers are more “natural” and include:

Wood powder, bark powder

Seed powder

Rice husk powder

Bamboo powder

Animal fibers (e.g., chicken feather powder)

These fillers are environmentally friendly but are limited by poor dispersion, high water absorption, and low heat resistance, so their application is currently more restricted.

3. Market Trends

In practice, most manufacturers prefer inorganic fillers due to cost-effectiveness, stable performance, easy mixing, batch consistency, and suitability for large-scale industrial production. Among them, calcium carbonate, talc, and sodium sulfate fillers remain the most widely used.

Plastic fillers are usually inorganic materials that help improve product quality.

4. Three Common Plastic Fillers and Their Applications

| Filler | Key Properties | Benefits | Applications |

|---|---|---|---|

| Calcium Carbonate (CaCO₃) | Abundant supply, stable source, slightly reduces tensile strength but increases modulus, increases density | Reduces cost, improves whiteness and hardness, enhances flowability, reduces shrinkage, improves dimensional stability | Blown films, injection molded parts, extruded pipes, hollow blow-molded bottles, household products |

| Talc | Layered structure, heat resistant, chemically stable, good dispersion | Increases stiffness, enhances heat resistance and dimensional stability, improves surface smoothness, anti-blocking in films | Automotive components, engineering plastics, home appliance parts, PE films |

| Sodium Sulfate | High transparency, easy to disperse, non-toxic, environmentally friendly, good compatibility with PE | Enhances film gloss and transparency, improves tensile and tear resistance, improves thermal stability, cost-effective | LLDPE agricultural films, LLDPE stretch films, HDPE films, LDPE films |

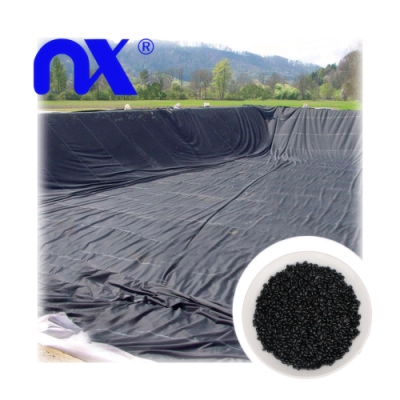

NUOXIN provides high quality plastic fillers with a variety of types.

5. Supplier Introduction: Nuoxin New Materials

Nuoxin is a leading manufacturer of filler masterbatches, color masterbatches, and functional masterbatches in Vietnam and surrounding regions.

Why choose Nuoxin?

Complete production lines: mature production for calcium carbonate, talc, sodium sulfate, and other filler masterbatches

Rich formulation experience: over 10 years of industry experience, supporting films, injection molding, and blow molding applications

Strict quality control: monitoring dispersion, moisture, melt flow, and batch consistency

Technical support: customized advice based on client equipment, processing conditions, and applications

Stable bulk supply: able to provide high-fill, transparent, and heat-resistant masterbatches

Whether for agricultural films, shopping bags, engineering injection parts, or multilayer films, Nuoxin offers tailored filler solutions.

6. Conclusion

Fillers are more than just “cost-saving additives.” Properly selected filler systems can help manufacturers improve product strength and heat resistance, enhance processing efficiency, ensure product stability, create differentiated competitive advantages, and achieve higher cost-performance ratios.

Choosing the right filler and a reliable supplier is a critical step for optimizing plastic formulations. If you want to learn more about calcium carbonate, talc, sodium sulfate, or other filler solutions, feel free to contact Nuoxin New Materials. We provide professional advice tailored to your production needs.