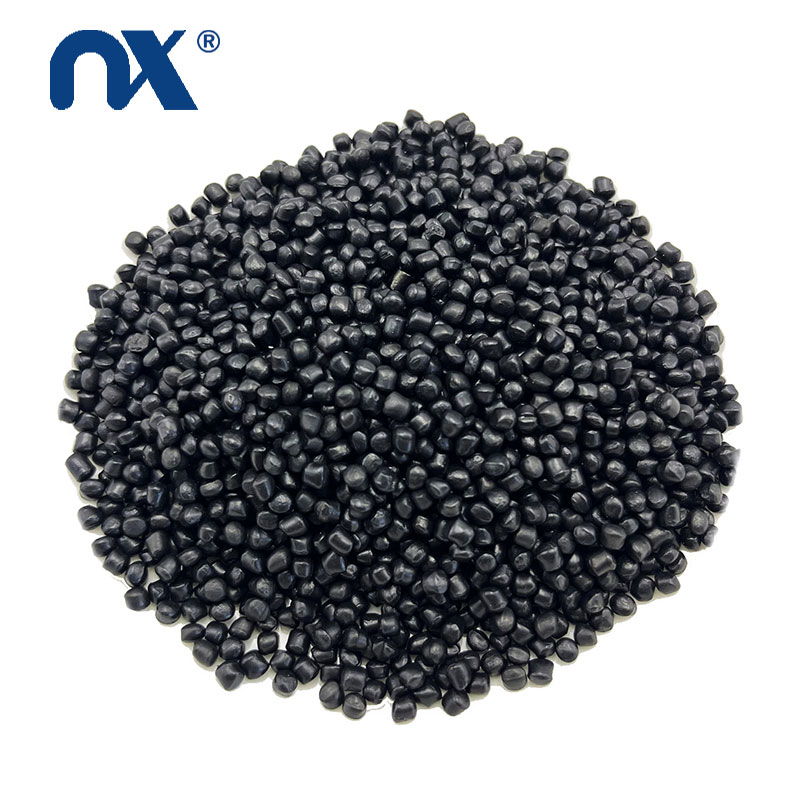

Black Master Batch

· Black Pigmentation: Delivers uniform black coloration to plastic products.

· UV Protection: Protects products from UV radiation, minimizing fading and degradation over time.

· Improved Mechanical Properties: Reinforces durability and strength without compromising processability.

· Cost Efficiency: Reduces the need for pure pigments, offering a more economical solution.

We are ISO9001 certified, and our Black Masterbatch products comply with quality standards such as FDA and RoHS.

How to Get Samples

To request a sample of our Black Masterbatch, please contact us by email or phone. Samples are available for testing, and our team is ready to assist with application guidance.

Product Overview

Our Black Master Batch is a high-performance additive designed to provide excellent color dispersion, UV protection, and enhanced durability to plastic products. Made with premium-quality carbon black and carrier resin(such as PP, PE), it is ideal for a wide range of applications, including injection molding, extrusion, blow molding, and film production. High-quality black masterbatch ensures uniform black pigmentation, making it the go-to solution for manufacturers seeking premium black coloration for their products.

Product Parameters

· Main Pigment: carbon black

· Pigment Content: 5%-50% (customizable)

· Carrier Resin: PE / PP / PS / ABS (customizable)

· Melt Flow Index (MFI): 2-15 g/10 min (customizable)

· Density: 1.2-1.5 g/cm³

· Moisture Content: ≤ 0.1%

· Appearance: Black granules

Product Details

Our Black Masterbatch is designed to provide consistent and intense black color to plastic products. It features high dispersion properties, ensuring even color distribution throughout the polymer matrix without streaks or spots. This masterbatch also enhances the UV resistance and stability of products, extending their lifespan even in harsh environments.

Application

· Film Production: Suitable for agricultural films, garbage bags, and stretch wraps.

· Blow Molding:black bottles, bucket,containers, and hollow products,toys,.

· Injection Molding: automotive parts, household goods, and industrial components,Storage boxes, furniture,.

· Pipe and Profile Extrusion: board,sheet, pipes, cables, and profiles.

Our Advantages

· High quality carbon black:Ensures superior color intensity and UV protection.

· Customizable Formulations: Tailored to meet specific application requirements, including pigment concentration and carrier resin.

· Excellent Dispersion: Guarantees streak-free, uniform coloration.

· Improve production environment hygiene: Manufactured using environmentally conscious processes to reduce waste.: Improve production efficiency

Production Workshop

Our production facility features state-of-the-art extrusion equipment and strict quality control systems. Each batch of Black Masterbatch undergoes rigorous testing to ensure consistent color strength, dispersion, and performance.

Company Strength

With over10 years of experience in the masterbatch industry, we are a trusted supplier serving customers worldwide. Our commitment to quality, innovation, and customer satisfaction has made us a leader in the field.

Exhibition

We regularly participate in global industry events such as Chinaplas and International Exhibition to showcase our Plastic Masterbatch innovations and connect with customers and partners.

FAQ

· Q1: What is the recommended dosage for Black Masterbatch?

A1: The typical dosage ranges from 1%-8% depending on the application and required color intensity.

· Q2: Is the Black Masterbatch compatible with all polymers?

A2: It is compatible with a variety of polymers, including PE, PP, ABS, and PS.

· Q3: Can I request a customized formulation?

A3: Yes, we provide tailored formulations to meet your specific requirements.

· Q4: Does it offer UV protection?

A4: Yes, our Black Masterbatch enhances UV resistance, making it ideal for outdoor applications.