Desiccant Masterbatch Addresses Moisture Challenges in Recycled Plastic Manufacturing

Calcium Oxide-Based Solutions Supporting More Stable and Practical Recycled Plastic Processing

For most people, plastic recycling is just one item on their environmental protection list; but in the eyes of recycled plastic factories, it is a revolution across the entire supply chain, from raw materials to responsibility.

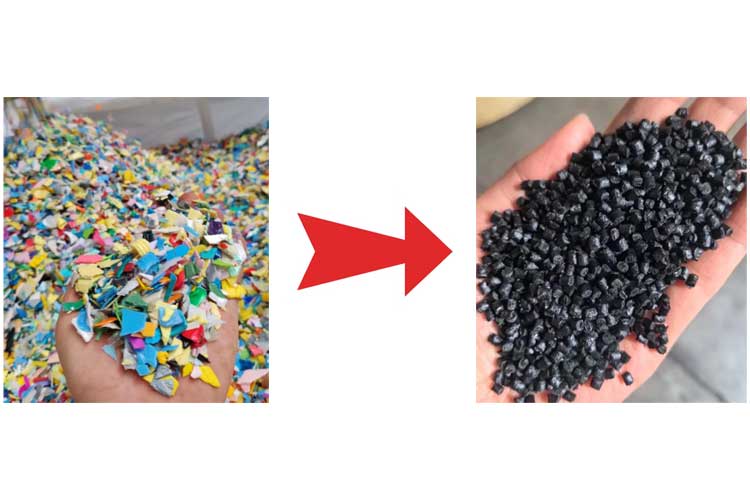

Plastic has long permeated the capillaries of our lives. Without a second life, this waste will become a long-term burden on the planet. Turning old plastic back into particles is not just about waste disposal, but about erasing the word waste from the dictionary and redefining resources.

Circulation is the only path of no return for the plastics industry, and also the easiest one.

Today, using recycled materials is no longer just a slogan, but a daily practice in factories: packaging films, municipal pipes, auto parts—recycled plastics are steadily and sustainably occupying a place on ingredient lists. It is pushing long-term cost curves downward for businesses and bringing production models closer to a true closed loop.

However, before entering the production line, recycled plastics must first pass the quality test.

In the past, recycled materials were labeled low-end. Today, customers expect them to run smoothly in high-speed injection molding machines and remain stable on extrusion lines for ten consecutive days. Compared to virgin materials, the biggest hidden enemy of recycled plastics is not impurities, but water—hidden inside the pellets, trapped in packaging gaps, and fluctuating with seasonal humidity.

The problems caused by water appear immediately: extrusion bubbles, injection molding streaks, melt fracture, batch color variation. Scrap rates rise, and order profits quietly evaporate.

Purchasing high-capacity drying equipment can solve part of the problem, but it comes with higher electricity consumption, space requirements, and production scheduling pressure. A more convenient option is the use of water-absorbing masterbatch.

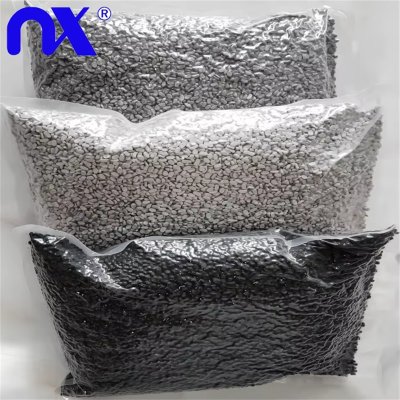

By incorporating calcium oxide as the active component into a masterbatch form, the desiccant can be evenly blended with recycled raw materials and begin absorbing moisture directly in the melting zone. No pre-drying is required, no additional equipment is needed, and standard mixing systems are sufficient to restore stable and smooth production.

Many pelletizing plants have also observed that even after pre-drying, recycled melts may still show fluctuations during extrusion. In such cases, desiccant masterbatch is often used as a process fuse.

By fine-tuning the addition ratio according to real-time moisture levels, processors can stabilize melt pressure, reduce material build-up at the die, and improve output consistency without major modifications to existing production lines.

Calcium oxide-based desiccant masterbatch is particularly suitable for recycled materials with fluctuating moisture content, especially in rainy or humid production environments. Its effectiveness is not proven by brochures, but through on-site trials: how much to add, when to add it, and whether bubbling disappears after application. Data provides the answer.

For recycled plastic factories, the core criterion for selecting a moisture control solution is simple: under real operating conditions—with their own machines, materials, and shifts—can it consistently reduce scrap rates? If yes, use it. If not, switch. Direct, practical, and cost-effective.