Filler Masterbatch: An Indispensable Component in Modern Plastics Manufacturing

As a professional plastic masterbatch manufacturer based in China, Nuoxin has worked closely with plastic processors across Africa, Southeast Asia, the Middle East, and South America for many years. During this time, we have seen how rising raw material costs, unstable resin supply, and increasing environmental pressure have reshaped the plastics industry.

In this changing environment, filler masterbatch is no longer viewed as a simple cost-reduction additive. From our production and application experience, it has become a key material solution that helps manufacturers balance cost, processing stability, and product performance.

Understanding Filler Masterbatch from a Manufacturer’s Perspective

At Nuoxin, filler masterbatch is engineered as a complete system rather than a single raw material. A typical formulation includes high-purity calcium carbonate, carefully selected carrier resins such as PE or PP, and functional additives designed to improve dispersion and processing behavior.

Compared with direct powder filling, masterbatch technology allows plastic processors to achieve more stable feeding, cleaner workshops, and consistent product quality. This advantage becomes especially important in high-speed extrusion, injection molding, and film blowing lines.

Our Production Process

Raw Material Control: Calcium carbonate is strictly screened for particle size, whiteness, and moisture content.

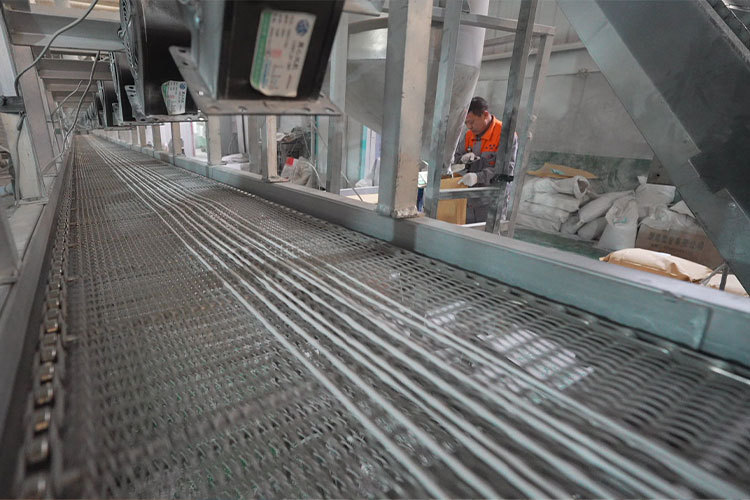

High-Shear Compounding: Twin-screw extrusion ensures uniform dispersion of filler within the polymer matrix.

Pelletizing and Cooling: Air-cooling or water-cooling systems form uniform granules suitable for automatic dosing.

Batch Inspection: Each production lot is tested to meet agreed technical parameters.

Why Plastic Processors Choose Filler Masterbatch

Cost Control Without Sacrificing Quality

One of the most direct benefits observed by our customers is material cost optimization. By partially replacing virgin polymer with calcium carbonate, manufacturers can reduce overall resin consumption while maintaining acceptable mechanical strength for many applications.

From real production feedback, filler masterbatch also improves heat transfer during processing, which often leads to shorter cycle times and lower energy consumption per unit.

Improved Processing Stability

Many customers initially approach filler masterbatch for cost reasons, but continue using it for processing stability. Properly formulated filler masterbatch helps reduce shrinkage, control warpage, and improve dimensional consistency, especially in injection molding and profile extrusion.

Application Experience Across Different Industries

Injection Molding

In injection molding applications such as household products, containers, and industrial parts, filler masterbatch helps improve rigidity and dimensional control. Many customers report lower rejection rates after switching from powder fillers to masterbatch form.

Film and Packaging Production

In blown film and cast film lines, optimized filler masterbatch improves bubble stability and thickness uniformity. This allows downgauging while maintaining sufficient stiffness, an important advantage in cost-sensitive packaging markets.

Pipe and Profile Extrusion

For pipes, sheets, and construction profiles, filler masterbatch contributes to better surface appearance, reduced thermal expansion, and improved long-term dimensional stability. These properties are especially valued in outdoor and infrastructure-related applications.

Sustainability Considerations in Practical Manufacturing

From a factory-level perspective, sustainability must be realistic and achievable. Filler masterbatch supports this by reducing dependence on fossil-based polymers and improving compatibility with recycled materials.

Many of our customers combine filler masterbatch with recycled resins to stabilize processing and appearance, making recycled products more consistent and commercially viable.

Key Technical Considerations for Successful Use

Correct carrier resin selection to match the base polymer

Stable dosing systems to ensure consistent addition rates

Temperature and screw configuration adjustments for high filler content

Ongoing quality monitoring during mass production

Future Development from Nuoxin’s Viewpoint

Looking ahead, Nuoxin continues to invest in advanced filler masterbatch solutions, including high-filler formulations, improved dispersion technologies, and customized solutions for recycled plastics.

We believe that closer cooperation between masterbatch manufacturers and plastic processors will play a key role in improving product consistency, reducing waste, and supporting sustainable growth in the global plastics industry.

Conclusion

Based on years of production and export experience, filler masterbatch is no longer just an additive—it is a strategic material choice. When properly formulated and applied, it helps manufacturers achieve better cost control, stable processing, and reliable product quality.

As a Chinese filler masterbatch factory serving global markets, Nuoxin remains committed to providing practical solutions, consistent quality, and long-term technical support to our partners worldwide.