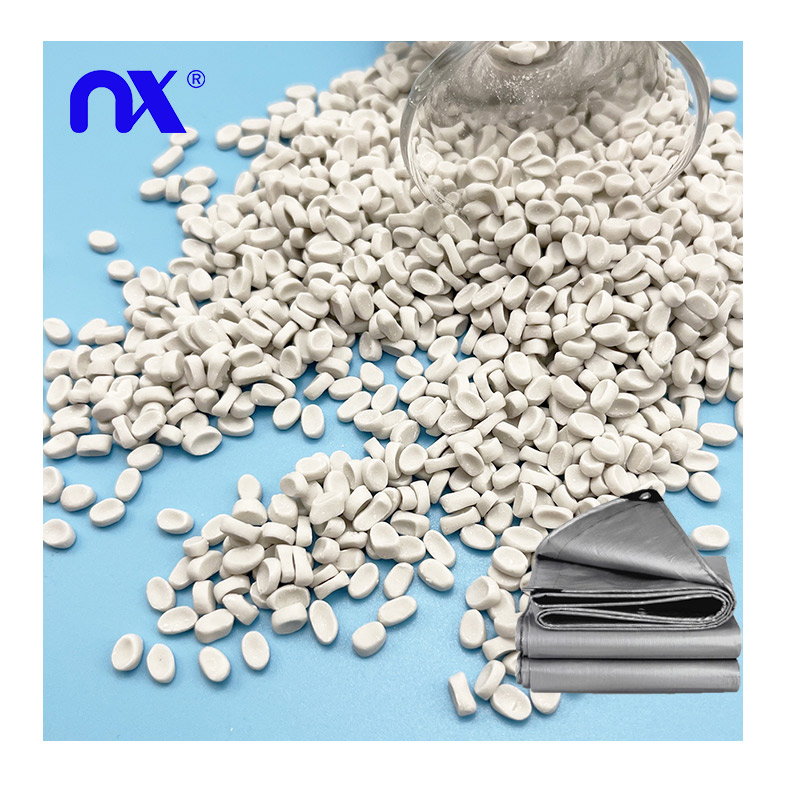

Calcium Carbonate masterbatch – Filler masterbatch

Product Advantages

Ⅰ:CaCO3 Filler masterbatch is a compound composed of calcium carbonate, virgin polyethylene resin and other dispersed plastic additives.

Ⅱ:Calcium Carbonate Filler is used as a filler to reduce the cost of the product, impart opacity, and increase stiffness to shaped products.

Ⅲ:This filler is compatible with virgin and recycled plastics (PP, PE, ABS, etc.) and is widely used in the production of woven PP bags and PP ropes with a high mixing ratio (5% - 50%)

Product Details

Our PP filler masterbatch combines the purest materials and technologies to provide customers with not only cost-effective solutions but also high-quality finished products.

PP filler masterbatch is a filler masterbatch containing 70-85% ultrafine calcium carbonate in base polypropylene. It reduces the volume formulation cost of the final product without compromising the quality (color, purity, dispersion and smoothness of the product surface). In addition, PP filler masterbatch can improve the impact force, surface hardness, strength duration and elongation of the product.

Product Parameters

| CaCO3 Content | 70-85% |

| Compatibility | PE, PP |

| Additives | Dispersion agent, processing aid |

| Processing Temperature | 120 – 280°C |

| Processing Technique | Woven sack, extrusion, blowing molding, etc |

| Filling rate | 10 – 50% |

Storage and Packaging

Keep at dry and cool place,Packing: 25 kg/bag

Applications

Filler masterbatches are used in injection molding, blow molding, film (single or multi-layer), sheet and tape applications. They offer the following benefits:

a) Injection and blow molding

Increased production due to faster mold cooling

Higher resistance to heat distortion, increased stiffness and hardness

In injection and blow molding applications, filler masterbatches can be added at rates up to 50%, but the most common levels are between 5-30%.

b) Film, Sheet, Sacks, Bags, Raffia

Higher stiffness, paper-like effect

Improved weldability and printability

In film applications, FILLER masterbatches are added at rates of 2-20%.

c) PE and PP tapes

Anti-fibrillation (also known as anti-splitting)

Lower raw material costs as they are often more economical than polymer resins

Improved weaving ability

Easier processing

In tapes, FILLER masterbatches are typically added at rates of 3-8%.

d) HDPE and PP pipes

High whiteness, can replace expensive white masterbatch

Low raw material cost, usually more economical than polymer resin

Higher stiffness

Good cold resistance, not easy to brittle at low temperature

The addition amount of FILLER masterbatch in the tape is generally 5-30%.