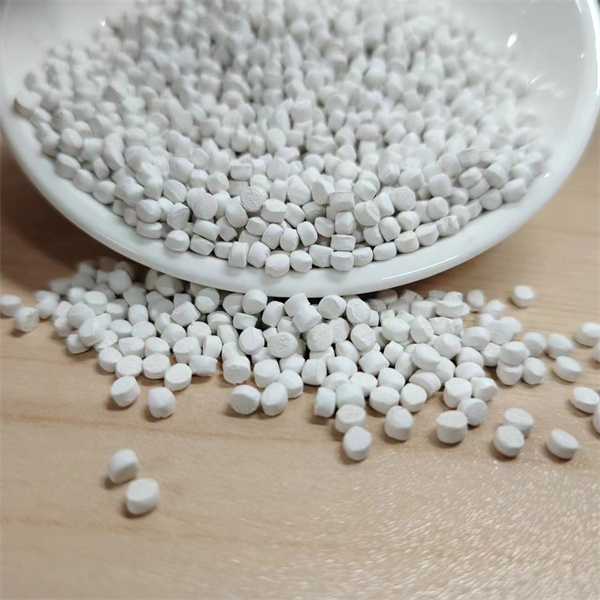

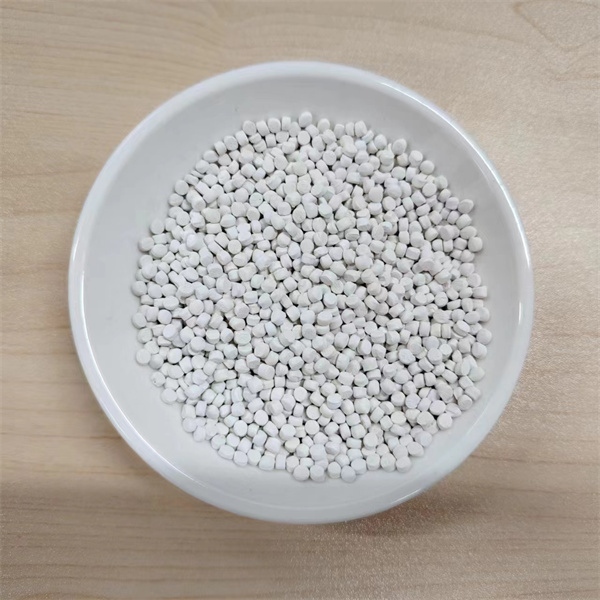

Plastic Masterbatch White Hdpe Carrier

Excellent Dispersion Uniformity:The white masterbatch disperses highly uniformly in raw resin, effectively preventing color spots, specks and other defects. It ensures consistent surface color for finished products, and works particularly well for items demanding high surface finish.

Strong and Long-Lasting Tinting Strength:With excellent tinting performance, only a small amount needs to be added to achieve the desired white effect. The coloring stays stable and long-lasting, hardly affected by external factors like light and temperature changes—keeping products bright white for a long time.

Excellent Pure White Expression:The white presented is pure and rich, free from color interference. It accurately meets the white tone needs of various products, stably rendering everything from bright snow white to soft milky white, and provides a reliable color base for product design.

Broad Carrier Compatibility:It is compatible with common resin carriers such as PE, PP and EVA. It integrates well with different raw resins without needing extra adjustments to production equipment or processes, greatly expanding its use in plastics processing.

Scientifically Optimized Addition Ratio:Mixing with raw resin at a ratio of 1:25-1:50 ensures great coloring and modification effects, while minimizing impact on the original properties of raw resin. This achieves an optimal balance between cost and performance.

product description

Physical Features

| Product name | White masterbatch |

| Package | 25kg/bag,1000KG/FIBC |

| Usage | Injection molding and blown film |

| Service | Customized colors |

| Index | numerical value |

Application

In injection molding, white masterbatch is key for efficient, high-quality white plastic production. It’s widely used, in almost all areas of daily life and industrial production.

In home appliance manufacturing, white masterbatch matters a lot. Parts like fridge door panels and washing machine control panel housings are always visible. They need high whiteness and color consistency.When using white masterbatch for injection molding, its titanium dioxide and other pigments go through a special dispersion process during production. They spread evenly at the nanoscale, mixing well with the carrier resin. In high-temperature melt molding, they fully blend with base resins (like ABS and PP) for appliance housings.This ensures pure, flawless surface color after molding. It avoids issues like graying, yellowing, or spotting – common when adding pigment powder directly. Home appliances look cleaner and more high-end, boosting their market competitiveness.

Our Advantage

Packing and Delivery

High Flexibility: Purchase volumes can be adjusted flexibly, minimizing capital investment.

Easy Operation: No special equipment is required; handling and loading can be performed manually.

High Identification: Printed information on small packages is clearer, making them easier for shop staff to identify.

Cost Advantage: Lower packaging and transportation costs per unit product.

Improved Efficiency: Automated equipment allows for rapid unloading, reducing labor costs and loading time, making it suitable for continuous, large-scale production.

Environmentally Friendly: Compared to small packages, ton-sized bags consume less material and generate less packaging waste, further aligning with green production principles.

Company Profile

FAQ

How long is the delivery time?

RE: We start shipping within 20 days after receiving 30% of the order amount. Or We commence shipping within 20 days after receiving 30% of the order amount.

Are there any certifications?

RE: Sure, our products are certified by FDA and MSDS.

What is the situation of the company's after-sales service?

RE: Our after-sales technical staff are highly skilled and capable of providing professional online technical guidance.