Moisture Absorbing Masterbatch

- Direct addition. No pretreatment needed. Moisture Absorbing Masterbatch can be mixed directly with base resin in the right proportions. It works for injection molding, extrusion, blown film and other processing. This removes the hassle of separate packaging. It also avoids uneven dispersion of traditional desiccants. It simplifies the production process a lot.

- Strong compatibility. It mixes well with many plastic substrates. Examples include PE, PP and PVC. It does not affect the substrate's processing or mechanical properties. It fits different production scenarios.

- Uniform dispersion. Large moisture absorption area. Desiccant particles spread evenly in the masterbatch. This creates more moisture-absorbing contact points in the finished product. So, it has higher moisture absorption efficiency. It is faster than traditional block or bagged desiccants.

- Continuous moisture absorption. Long-term stability. The Moisture Absorbing Masterbatch is encapsulated in carrier resin. It absorbs moisture more gently. It releases its moisture absorption capacity slowly. This extends the effective moisture absorption cycle. It is especially good for products needing long-term moisture resistance.

Product Introduction:

Plastic Moisture Absorbing Masterbatch fits all companies making products with recycled PE and PP plastics. Trace moisture in raw materials harms plastic product production badly. So companies usually use extra drying equipment. This wastes energy and manpower. It also raises product costs.

Application:

Moisture Absorbing Masterbatch are very convenient. They simplify production processes a lot. In practice, you just mix them thoroughly with base resin in specific ratios. Then they work well with common plastic processing methods. These include injection molding, extrusion, and blown film.

Moisture control matters in blown film production too. Traditional methods need raw materials to be extremely dry. They rely on complex drying equipment and strict procedures. This is to ensure film quality. Desiccant masterbatches make it simpler. Mix them with resin in the right proportions. Then you can use them directly for film blowing. During the process, they absorb moisture effectively. The films turn out uniform. No holes, no wrinkles. Quality gets better. What's more, you don't need as many drying resources. This streamlines the whole blown film process. It cuts costs too.

Our service:

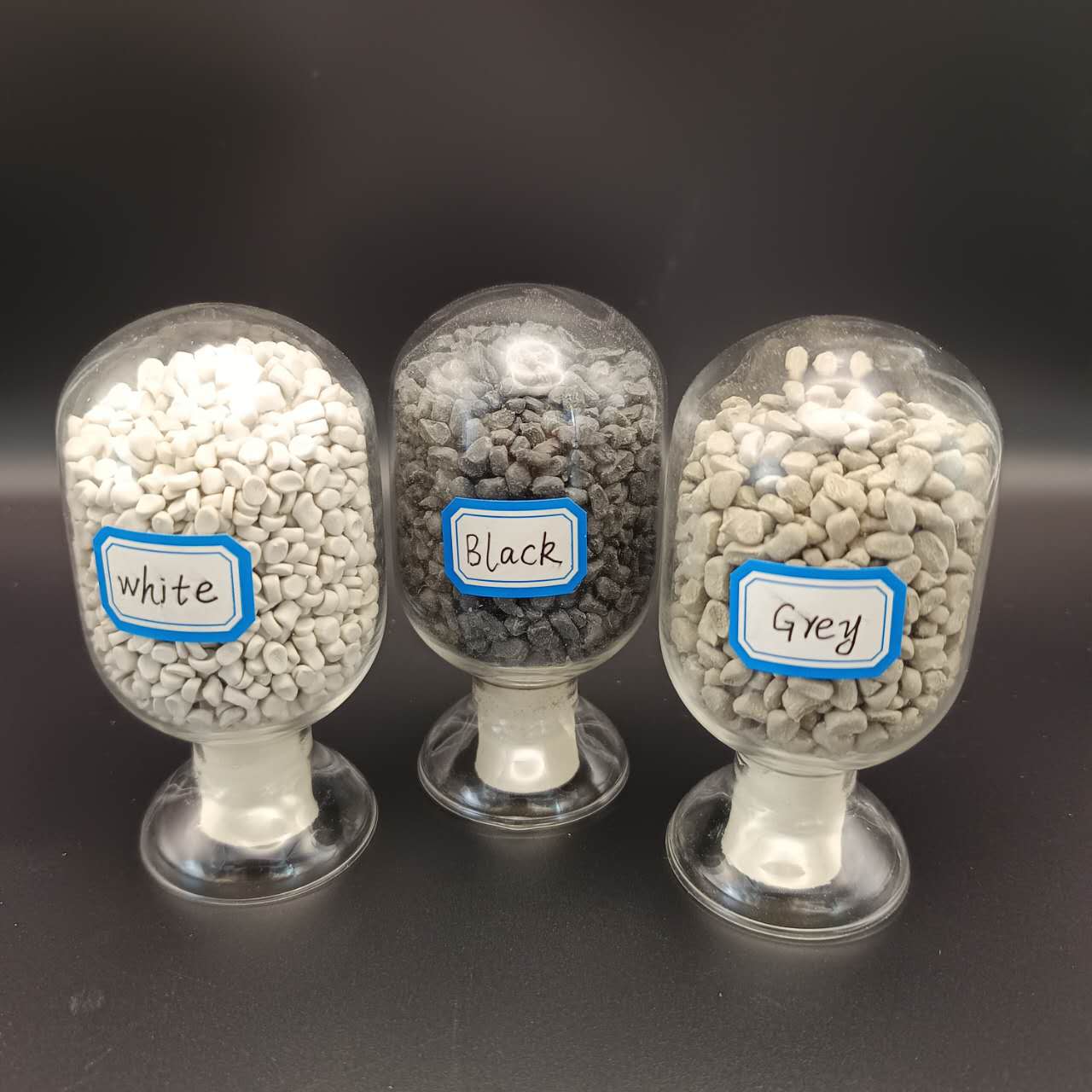

Package and stock:

We pack Moisture Absorbing Masterbatch in 25kg bags. Each bag has a moisture-proof liner. Labels include batch numbers and product details. This makes tracking easy. Our warehouse keeps inventory stable. So we can deliver quickly. Customers can ask for free samples. The maximum is 5kg. But the buyer pays the shipping cost. We offer technical support. We help customers adjust dosage. This ensures the best results. Our team also gives advice. We cover color consistency and resin compatibility. Fast response and professional service are important to us.

Exhibition: