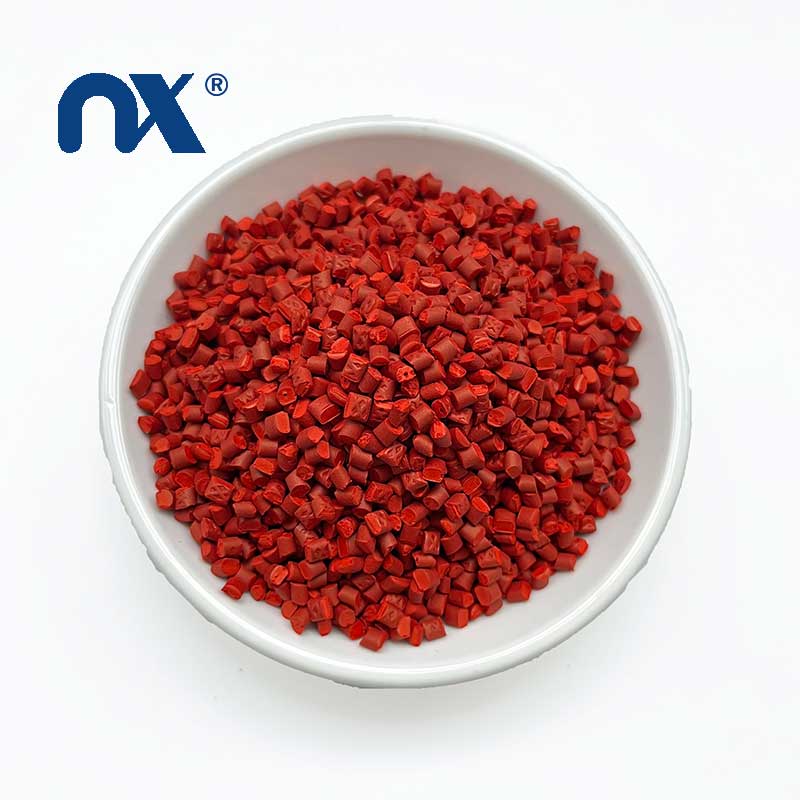

About Nuoxin & Our Red Masterbatch

We are a factory in Shandong. The area gives us easy access to raw materials, skilled technicians, and strong logistics. Since 2016 we focus on color masterbatch, functional masterbatch, and filler masterbatch. Our red masterbatch is one of our best sellers. It works for packaging, home appliances, automotive trim, building materials, and 3D printing. We ship to customers in more than 50 countries.

We keep things practical. You get a product that is easy to dose, mixes evenly, and keeps the same shade batch after batch. We match Pantone and RAL, and we can make special effects like pearlescent or metallic red on request.

Product Overview

Our Red Color Masterbatch combines high-purity red pigments with a chosen resin carrier. The result is a pelletized colorant that blends cleanly and gives a vivid red tone. You can pick the carrier to match your base polymer: PE, PP, ABS, PET, or PLA. The pellets are stable and easy to handle.

Carriers available: PE, PP, ABS, PLA, PET

Color matching: Pantone, RAL, or your sample (ΔE < 1)

Use levels: 0.5%–3% typical

Main Features

We keep the features straightforward so engineers can evaluate quickly:

Custom color — accurate matching and locked formulas for repeat orders.

Safe — ROHS, REACH, and FDA grades available; no heavy metals.

Heat stable — suitable for 180–300°C depending on the carrier.

Low dosage — cost effective, short cycle impact.

Multiple processes — injection, blow molding, extrusion, and 3D printing.

Technical Parameters

| Item | Specification |

|---|---|

| Appearance | Pellet / Granule |

| Melt Flow Index | 250 g / 10 min (adjustable by carrier) |

| Moisture | ≤ 0.3% |

| Heat Resistance | 180°C – 300°C (carrier dependent) |

| Recommended Dosage | 0.5% – 3% |

| Packing | 25 kg bag (PP woven + PE liner); jumbo bags on request |

| Shelf Life | 12 months in cool, dry storage |

Production Process & Quality Control

We select pigments that pass critical tests for heat and light stability. The pigments are blended with resin and additives in a controlled environment. We use twin-screw compounding to get even dispersion. The melt is pelletized and cooled, then every batch goes through QC checks. We record MFI, color readings, and dispersion data. If a customer needs a TDS, we provide it with the shipment.

Our lab runs color matching with spectrophotometers. We hit ΔE targets and store the master recipe. When you reorder, the shade matches the prior run. That saves time and avoids re-approval cycles on your end.

Applications

This red masterbatch is practical for many products. Typical uses include:

Packaging: food bottles, cosmetic jars, medicine containers.

Home appliances: housings, bezels, knobs.

Automotive: interior trims, decorative parts.

Daily goods: toys, tableware, storage bins.

Building materials: colored panels, PVC profiles.

3D printing: PLA red filament for prototypes and visual parts.

Customer Cases

We work with small and large customers. A European cosmetics brand needed a petal-red for PET containers. They required a PET-grade formulation with no odor and high gloss. We provided matched samples within three days. After a short trial, they accepted the formula and moved into production. The color stayed stable in subsequent shipments.

Another example: an outdoor furniture maker in Southeast Asia needed a UV-resistant red for polypropylene chairs. We supplied a weather-resistant grade and recommended a slightly higher pigment load. The chairs retained color after months in the sun, and the customer reduced returns and complaints.

Customization Services

We can tailor color, function, and packaging. Send a Pantone, RAL, or a part sample and we’ll match it. Want pearlescent or metallic red? We do that. Need food-contact approval or flame retardance? We formulate to meet those specifications. Packaging choices include 25 kg bags, 500 kg bulk, or 1 t jumbo bags. OEM labeling is available.

Packing & Logistics

Standard packing is 25 kg woven bags with a PE inner liner. For humid destinations we use moisture-barrier palletization. Samples go by express courier. Bulk shipments move by FCL or LCL sea freight, or by road for domestic orders. We include certificates on request and handle export documentation to simplify customs clearance.

Why Customers Choose Us

Factory direct prices. No middleman.

Fast sample turnaround (typically 3 days).

Mass production lead time 7–15 days.

Dedicated technical support and trial guidance.

Large stock and multiple warehouses for quick delivery.

FAQ

Q: What’s the MOQ?

A: 25 kg for standard colors; 500 kg for custom colors.

Q: Can I get a free sample?

A: Yes. 100 g free, buyer pays shipping. Larger samples are available and can be credited to order.

Q: How long to deliver?

A: 3–7 days for stock colors; 7–15 days for custom colors.

Q: Do you export?

A: Yes. We export worldwide and provide ROHS, FDA, and MSDS documents as required.

Q: What if quality issues arise?

A: We respond within 24 hours. We propose a solution within 3 days. Refund or replacement is offered if the problem is confirmed and caused by us.

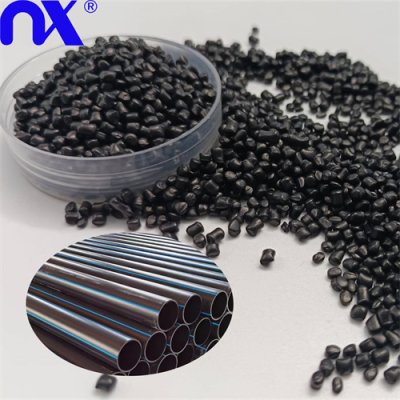

Other Products You May Need

In addition to Red Color Masterbatch, we also manufacture:Our product range ensures customers can source multiple solutions from a single, trusted supplier.

Contact & Samples

If you want samples, technical sheets, or a price quote, contact our export team. We will reply quickly and help you run trials on your line.