Talc Masterbatch

Stronger Containers – Increases stiffness and durability.

Heat Resistance – Withstands higher temperatures.

Cost Saving – Reduces use of virgin polymer.

Better Appearance – Gives smooth and clean surface.

Eco-Friendly – Lightweight and supports sustainability.

What Is Talc Masterbatch?

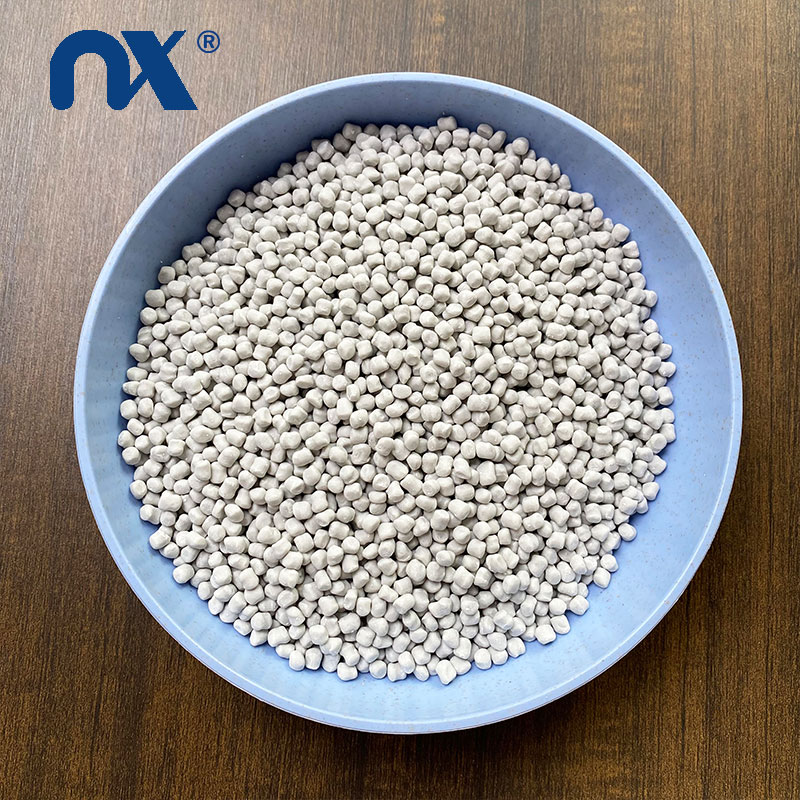

Talc masterbatch is a kind of filler masterbatch. It’s made by mixing fine talc powder with plastic carriers like PE or PP. It’s commonly used as a polypropylene filler or PE filler masterbatch for food packaging. Talc is a natural mineral. It’s stable, soft, and resists chemicals. When you add it to plastics, it makes them stronger and more durable. It also helps cut down on production costs.

In food container manufacturing, talc masterbatch offers clear advantages. It increases container rigidity and thermal resistance. It gives surfaces a smooth and clean look. These features make it ideal for lunch boxes, takeaway trays, soup bowls, and other catering packages.

Why Food Containers Need Talc Masterbatch

The global demand for disposable food containers is rising. Restaurants need strong and safe packaging. Cafés and supermarkets want affordable and reliable solutions. Food delivery services require containers that can handle hot meals and resist oil. Consumers expect materials that are safe for direct food contact.

Traditional plastics without fillers are weaker. They can bend or deform under heat. They often require more resin, increasing costs. Talc masterbatch solves these issues by improving strength and reducing resin use.

Main Benefits in Food Packaging

Rigidity: Increases stiffness of thin-walled containers.

Heat Resistance: Prevents deformation from hot meals or soups.

Cost Savings: Replaces a portion of expensive resin with filler.

Surface Quality: Creates smooth, glossy finishes with fewer defects.

Food Safety: Certified safe for direct food contact packaging.

Performance Advantages of Talc Masterbatch

Improved Dimensional Stability: Containers keep their shape during transport and storage.

Enhanced Heat Deflection: Reliable performance with hot or oily foods.

Reduced Warpage: Prevents uneven shrinkage in plastic parts.

Lower Resin Consumption: Helps reduce raw material costs.

Better Dispersion: Pigments and talc spread evenly for consistent results.

Technical Data

| Carrier Resin | PE, PP |

|---|---|

| Filler Content | 70-80% talc |

| Application | Food containers, trays, boxes, bowls |

| Dosage | 5-30% depending on product |

| Safety Standards | ISO, ROHS, FDA certified |

Applications in Disposable Food Containers

Talc masterbatch is ideal for thin-walled, lightweight containers used in fast food and takeaway packaging. Polypropylene lunch boxes, PE soup bowls, and tray lids all benefit from talc fillers.

By adding a controlled ratio of polypropylene filler or PE filler masterbatch, manufacturers can produce packaging that is affordable, functional, and reliable in demanding food service conditions.

Case Study: Success in Food Packaging Industry

A food container producer in India faced high production costs and container deformation when handling hot curry dishes. After introducing our talc masterbatch, containers became stronger and more heat-resistant. Resin usage dropped by 20%, lowering costs significantly.

Another client in Canada had frequent breakage of takeaway boxes during delivery. With talc masterbatch, rigidity improved, surfaces became smoother, and customer complaints decreased. These examples show the practical benefits of talc fillers in food packaging.

Safety and Compliance

Food packaging materials must meet international safety standards. Our talc masterbatch complies with ISO, ROHS, FDA, MSDS, and TDS certifications. Containers made with our filler are safe for food contact. Manufacturers do not need to worry about chemical contamination, odor, or harmful migration into food products.

Global Market Trends

Demand for disposable food containers is growing in North America, Europe, Asia, and the Middle East. Urbanization, busy lifestyles, and food delivery apps increase the use of packaging. Governments also encourage recyclable and lightweight packaging.

Talc masterbatch supports these trends by reducing resin use, lowering costs, and improving product strength. As a leading filler and masterbatch supplier in China, we export to Canada, the US, India, Vietnam, Thailand, and other countries.

Packing and Delivery

Our talc masterbatch is packed in 25kg moisture-proof bags. We maintain strong stock for fast delivery. Bulk orders are shipped within 7-10 days. Customers benefit from stable supply, consistent quality, and reliable logistics support.

Conclusion

Talc masterbatch is a essential additive for food container manufacturing. It improves rigidity, reduces resin costs, and ensures food safety. By choose our polypropylene filler and PE filler masterbatch, manufacturers gain higher efficiency, lower costs, and better product performance. Proven results in Canada, India, and other markets show that our talc masterbatch supports the growth of the global food packaging industry.