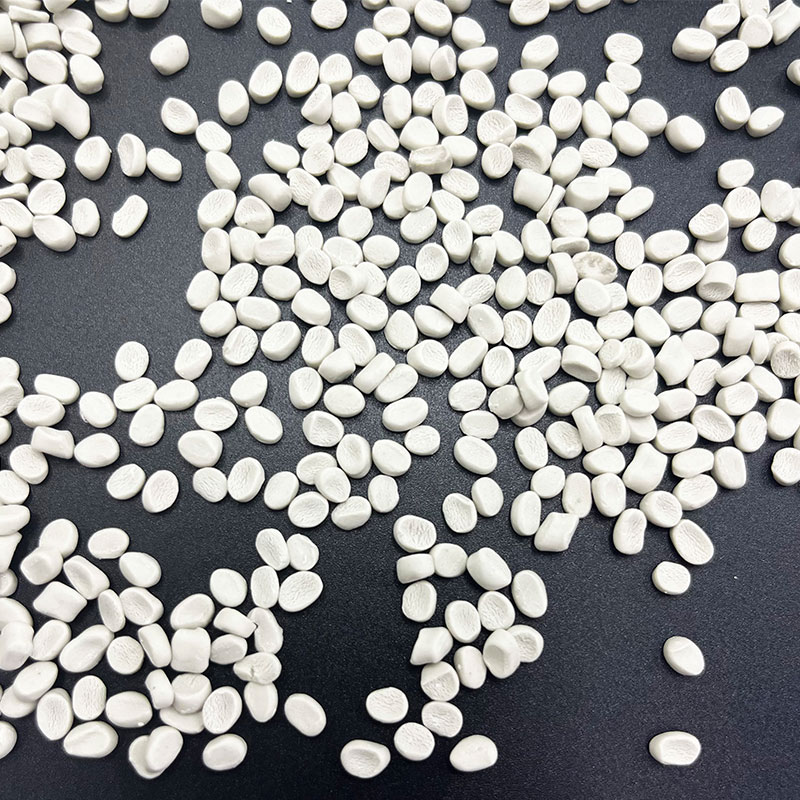

CaO Masterbatch

High Moisture Absorption – Quickly removes moisture during plastic processing.

Cost-Saving – Eliminates pre-drying, reducing energy and labor costs.

Wide Compatibility – Works with PE, PP, ABS and more.

Enhances Recycled Materials – Improves quality of recycled plastics.

Stable Quality – High-purity CaO with consistent performance.

Fast Delivery – Large stock and quick supply for all orders.

At Nuoxin we make a CaO Masterbatch (often called masterbatch cao or master batch cao) that many producers have come to rely on when moisture threatens yield or finish. This product is not a theoretical lab item — it's used every day on production lines to cut down scrap, avoid long drying cycles, and keep throughput steady.

Features & Practical Advantages

Our CaO masterbatch is formulated around high-purity calcium oxide dispersed into a PE/PP carrier. When mixed into resin at low dosages it reacts rapidly with free moisture present in pellets or regrind and locks that moisture into an inert form during melt. In practice this means fewer bubbles, less silvering on molded parts, and fewer stuck-ups on high-speed blown film lines.

We keep the recipe pragmatic: enough CaO to be effective (typ. 70–80% active), with carrier and dispersants selected to avoid dusting and to give a steady melt flow. Operators tell us it behaves predictably on lines — there’s no surprise stickiness, no extra screening, and dosing is simple.

Application Scenarios & On-site Examples

The product finds regular use in blown film, injection molding, extrusion sheets, and recycling lines. For example, a small blown-film plant in Vietnam that had chronic bubble issues during the rainy season added 3% of our CaO masterbatch to their LDPE blend. Within days they reported a ~35% drop in scrap, smoother film surface, and a small but meaningful increase in machine uptime because they no longer paused the line for emergency drying.

Another customer making injection-molded crates replaced a lengthy oven-drying step with a 2% addition of master batch cao. They saved on energy, reduced cycle interruptions, and noted better part consistency when recycling content varied between batches. These are practical results — not lab promises.

R&D, Quality Control and Compatibility

We don’t treat masterbatch cao as a single formula for every case. Our R&D lab routinely runs tests to match CaO grade, particle size, and carrier selection to the target polymer and processing speed. Particle sizing is important: too coarse and dispersion suffers; too fine and dust handling becomes a problem. Our standard grades are tuned for PE/PP systems, but we also supply adapted variants for ABS blends or special coextrusion setups.

Every production lot undergoes moisture uptake testing, melt flow checks, and dispersion assessment before it leaves the plant. We publish these internal QC numbers with customer samples on request — MFI, CaO active percentage, and measured water uptake are standard. This transparency helps plant engineers trust that adding CaO masterbatch won't be a blind experiment.

Production Capacity, Stock and Logistics

Our Shandong facility runs multiple twin-screw extrusion lines dedicated to desiccant masterbatches. Monthly capacity for CaO masterbatch is in the low thousands of tonnes, and we typically keep rolling stock of several hundred tonnes to support fast turnarounds. For regular customers we can set safety-stock levels and synchronize shipments to reduce lead time risk.

Shipping is palletized in moisture-barrier 25 kg bags with inner liners. For export we perform extra moisture protection (vacuum-sealed pallets) when requested. Lead time for standard orders is commonly 15–20 days after deposit; expedited slots can be discussed when inventory is available.

Product Parameters (Typical Spec)

| Parameter | Value |

|---|---|

| Carrier | PE / PP (customizable) |

| CaO Active | 70% – 80% |

| Melt Flow Index | 5 – 20 g/10min (depending on grade) |

| Form | White granules |

| Recommended Dose | 1% – 5% (process-dependent) |

| Moisture Uptake | > 20% of own weight (lab measured) |

| Packaging | 25 kg moisture-barrier bags |

Standards & Safety

We follow standard safety and environmental practices. Material safety data sheets (MSDS), test reports and basic compliance certificates (RoHS/REACH) are available on request. For food-contact applications we provide traceable sourcing and documentation for the polymer carrier; CaO masterbatch grades intended for food-film applications are tested specifically for residues and odor.

How to Use (Practical Notes)

- Run a short trial: mix a measured quantity (2–3%) into the batch and observe bubbles, surface finish and melt pressure over a full shift.

- Avoid exposing masterbatch bags to high humidity during storage — keep them sealed.

- Use a gravimetric feeder for consistent dosing on continuous lines; for small shops, pre-blending in a tumble mixer works well.

- If your recycled content varies widely, slightly higher dosing (up to 4–5%) can smooth the fluctuations.

FAQ

Q: Is this product suitable for all polymers?

A: Our standard grades are optimized for PE and PP. We can provide consultation and adapted grades for other systems such as ABS or special coextrusion blends.

Q: Will CaO masterbatch affect color or mechanical properties?

A: When used within recommended dosing it does not degrade mechanical properties; we advise compatibility trials for color-critical applications.

Q: Do you supply samples?

A: Yes — we ship 5-25 kg trial samples with basic test data so customers can run line tests before placing volume orders.

If you'd like a specification sheet (TDS/MSDS), sample or a short telephone consultation about integrating cao master batch into your line, email zina@nuoxinplastic.com or call +86 18660167636. We can run a short dosage simulation with your process data and suggest a starting trial recipe.