High Quality Carbon Black Masterbatch Manufacturer

Compatible with mainstream plastic materials such as PP and PE, offering wide compatibility.

Suitable for injection molding, ensuring melt flowability.

Suitable for film blowing, ensuring uniform film thickness.

Owns a professional black masterbatch production facility with a mature production system.

Quick shipment upon order confirmation, shortening delivery lead times.

Product Description

Moreover, this black masterbatch offers flexible customization. Professionals adjust formulas and parameters based on customers’ specific needs and actual production conditions, ensuring the product meets their standards. Its cost-effectiveness boosts competitiveness, making it a preferred coloring solution in many industries.

Key Attributes

Region of Origin | Shandong,China |

Name of Brand | Nuoxin |

Feature | Virgin or recycled materials |

concentration | 5%-50% |

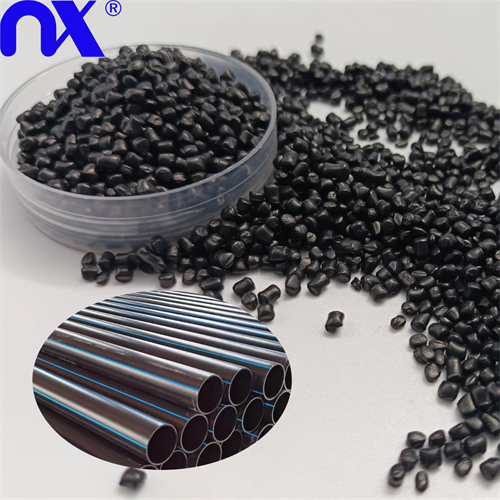

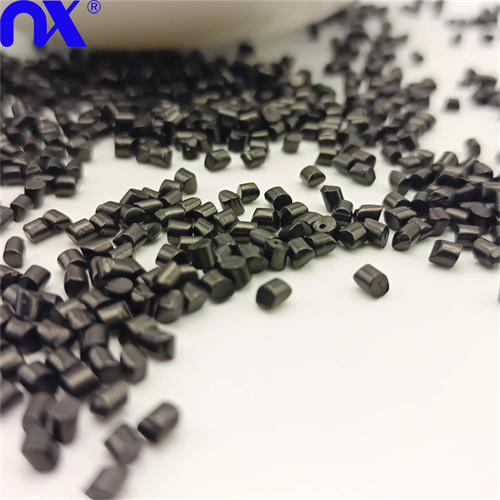

product name | black masterbatch |

color | black |

shape | grain |

carieer | PE/PP |

Melt Index | 1-40g/10min |

Application

As a commonly used type of masterbatch in plastic processing, black masterbatch is widely used in injection molding plastic basins, buckets, toys, stationery and other fields due to its advantages such as uniform coloring, stable performance and convenient use. Its core function is to provide plastic products with a uniform and long-lasting black appearance. At the same time, it can be given additional functions such as UV resistance, weather resistance and reinforcement according to the needs of the application scenario.The Characteristics of black masterbatch:

Carrier Resin: Match the resin to the base material. Use PP carrier for PP basins. Use PE carrier for PE barrels. This ensures compatibility.

Pigment: Prefer carbon black. It has strong tinting power, low cost and inherent aging resistance. Avoid dyes. Dyes easily migrate.

Additives: Add antioxidants. Add UV absorbers (for outdoor barrels). For food-grade products, add a food-grade dispersant. An example is polyethylene wax.

Packing

- Standard 25kg/bag Specification: As a common standard for large-scale industrial procurement, it balances loading efficiency and handling convenience. It suits mass production and long-term supply, reducing material handling frequency and improving logistics efficiency for industrial clients.

Paper-polymer Composite Pouch (for 25kg): Integrates paper’s rigidity and polymer’s moisture resistance. The paper layer prevents deformation during stacking/transportation, while the polymer layer isolates external moisture, avoiding moisture absorption of masterbatch and ensuring product integrity in long-distance or humid conditions.

PE Valve Bag (for 25kg): Features excellent sealing performance. Its special valve structure enables easy filling and tight sealing post-filling, preventing dust leakage (to keep the working environment clean) and external impurity entry, thus maintaining masterbatch purity and quality stability.

Polyethylene Adhesive Sachet: Lightweight and compact, ideal for small-batch trials, lab tests or precise dosage scenarios. The adhesive seal allows quick opening, effectively isolating masterbatch from the outside to prevent pollution and preserve its original performance.

Why choose us

We always consider quality the lifeblood of our company.We have established a comprehensive quality control system.This system covers every step from raw material procurement to finished product delivery.

Raw Material Selection

This ensures our products are non-toxic.It also ensures our products are odorless and environmentally friendly.Our products meet stringent standards.These standards apply to food contact, medical, and children's products.

Process Control

This prevents unqualified products from entering the market.

After-Sales Traceability

Exhibition

FAQ

1.What's the delivery time?

Answer:After the order is confirmed, we will deliver the goods in about a week at the soonest. The specific delivery time depends on the customer's purchase volume.

2.Does the product have after-sales guarantee?

Answer:Of course, if you are not satisfied with our product quality or service, please feel free to give us feedback immediately.

3.Support customer sample customization

Support customized production of film-blowing grade black masterbatch, food grade black masterbatch, general black masterbatch, sanitary black masterbatch and functional black masterbatch according to customer requirements.

4.Stable supply

Monthly production capacity is 6,000 tons, annual output is 7,200 tons, sufficient inventory and stable supply.