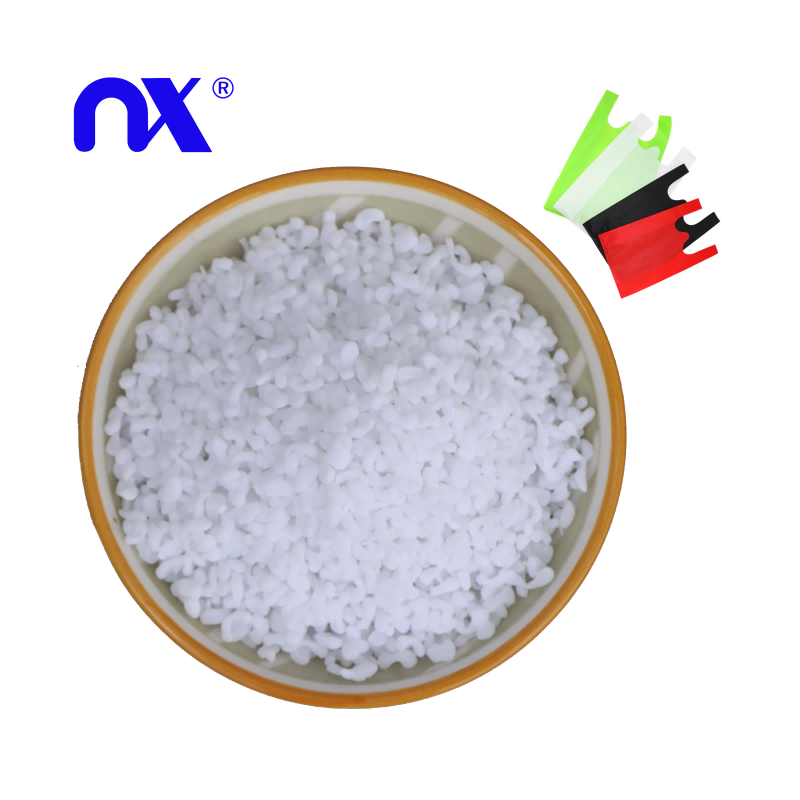

Sodium Sulphate Filler Masterbatch

- Low Raw Material Cost:Sodium Sulphate Filler Masterbatch has two sources: natural mineral or chemical by-product. It’s easy to mine and purify, and cheaper than base resins and traditional inorganic fillers.

- Strong Compatibility with Fillers:If you pair sodium sulfate with carrier resins (think PE or PP) and dispersants (like stearic acid or polyethylene wax), it spreads evenly throughout the polymer matrix. Even when you add it at levels of 10% to 30%—or sometimes even more—it hardly clumps up or causes layers to separate. This means it can take the place of a lot of expensive resin raw materials, which directly brings down the raw material cost for finished products.

- No Hit to Processing Efficiency:When compared to some low-cost fillers (such as low-quality talc), sodium sulfate filler masterbatch flows much better. Cranking up the amount of filler used won’t slow down production efficiency. And that, in turn, helps cut energy use and labor costs indirectly.

Product Description

Sodium Sulphate Filler Masterbatch is a functional masterbatch made of polyethylene resin and transparent filler as the main raw materials through extrusion and granulation. Adding a certain proportion of this masterbatch to products such as film products, sheet products, and injection molded products will basically have no effect on the appearance and physical properties of the products, and will also help reduce costs.

We provide 800-2000 mesh sodium sulfate filler masterbatch. It has the effect of not reducing product quality and reducing costs.

Specification:

| Product Name | Sodium Sulphate Filler Masterbatch |

Melt | 1-5g/10min |

Density | 2.0-2.4g/cm³ |

barium sulfate content | 79%—83% |

Compared with ordinary filling masterbatch, transparent filling masterbatch is characterized by adding transparent filling masterbatch to PP,PE, which has little influence on PP,PE transparency, and transparent filling masterbatch can also be widely used in film, sheet material, pipe, container and other fields.

Application Area

Sodium Sulphate Filler Masterbatch has a similar refractive index to plastics like polyethylene and polypropylene. Therefore, when added to plastics for blown film production, it has minimal impact on film clarity. Compared to calcium carbonate filler masterbatches, sodium sulfate filler masterbatches can enhance product transparency. For example, when producing transparent plastic bags, adding a certain percentage of sodium sulfate filler masterbatch allows the bags to maintain a high level of transparency without affecting their appearance or performance.

The film's opening properties make the bags easier to open and convenient for users.

Compatibility with blown film processes: In the blown film process for transparent plastic bags, sodium sulfate filler masterbatch is mixed with the plastic raw material in a specific proportion and then added to an extruder. After heating, plasticization, and extrusion, a tubular billet is formed. Air is then blown into a film, cooled, and formed, and then wound. Sodium sulfate filler masterbatch is well compatible with standard blown film equipment, requiring no major modifications. It also minimizes wear and tear on mechanical equipment, effectively reducing maintenance costs.

Widely used in mold products, bag products, sheet products and injection molding products.Agricultural film, garbage bags, Geomembrane, packaging film, composite film, construction film, Drainage Pipe three-layer co-extrusion film, five-layer co-extrusion Film.Food Containers, milk film, drinking water pipes and other industrial and agricultural fields, food safety.

Product Packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.We use paper-plastic composite bags, PE valve bags, PE adhesive bags, PE transparent valve bags for storage, each bag has a net weight of 25kg, and store it in a dry place.

Company Profile

Qingyun County Nuoxin Plastic New Materials Co., Ltd. was established in January 2016. It is a four-functional masterbatch manufacturer integrating product research and development, production, sales and technical services. It mainly produces: filler masterbatch, desiccant masterbatch , black masterbatch, colored masterbatch, etc. It covers an area of more than 40 acres and has an annual production capacity of 78,000 tons. The masterbatch produced can be widely used in blow molding, injection molding, pipes, drip irrigation tapes, plastic braiding, blown film, cable sheathing, geomembranes, geogrids, agricultural mulch films, Lunch boxes, PE water supply pipes and other industries. All products of Nuoxin Plastic undergo strict quality inspection. The company has passed international quality, environment, occupational health and safety management system certification, ROHS certification and multiple industry standardization certifications.

Why Choose Us

Choose us, and you get more than equipment and support—you get a partner deeply rooted in the masterbatch industry, dedicated to making your school-enterprise cooperation drive real value.

FAQ

1.Are you a company or manufacturer?

We are a manufacturer that located in De Zhou,Shandong. and We are major in producing this since 2016.

2.Can you send me a sample?

Sure.we will send you the samples if you want.

3.What payment methods are supported?

Answer: T/T, L/C.

4.What are your advantages?

Answer: A powerful factory with a complete range of products and competitive prices.