Na2SO4 Filler Masterbatch

1. Over 10 years of manufacturing experience, stable product performance

2. Strong production capacity, 500 tons of stock in stock, and fast delivery, as fast as 3 days

3. Extensive product range, one-stop shopping

4. Strict quality control and international certifications ensure consistent quality

5. Professional technical support and customized services, with complimentary technical formulas

6. Recruiting global agents with generous commissions

Product Overview

Na₂SO₄ filler masterbatch is a high-performance functional masterbatch composed of polyethylene resin and high-purity sodium sulphate filler. It is specially developed to enhance transparency, reduce production cost, and maintain the overall mechanical and visual quality of plastic products.

When used in film, sheet, or injection molding production, it provides excellent dispersion, high brightness, and improved process stability. This masterbatch helps manufacturers achieve cost-effective production without sacrificing quality or transparency.

Technical Specifications

| Main Ingredient | Sodium Sulphate (Na₂SO₄) |

|---|---|

| Powder Fineness | 2000 -6000 Mesh |

| Powder Content | ≥ 80% |

| Carrier Resin | LDPE / HDPE / PP / PE |

| MFI (190℃, 5KG) | 5 – 21 g/10min |

| Melting Point | 110℃ |

| Density | 1.45 g/cm³ |

| Add Ratio | 10% – 65% |

| Single Screw Addition | 10% – 50% |

| ABA Layer B Addition | 20% – 80% |

| Certificates | RoHS, FDA ,MSDS,TDS,SGS, ISO 9001 |

Key Features

High transparency with no loss of optical clarity.

Significant cost savings through resin replacement.

Excellent dispersion and processing stability.

Eco-friendly and compliant with international safety standards.

Compatible with LDPE, HDPE, PP, and PE resins.

Ideal for extrusion, injection molding, and blown film processes.

Applications

Na₂SO₄ filler masterbatch is suitable for a wide range of plastic products and processes:

Packaging Films: Agricultural films, garbage bags, food packaging, composite and construction films.

Molded Products: Bottle caps, lunch boxes, thin-walled items, and transparent containers.

Pipes & Sheets: Drainage pipes, geomembranes, three-layer and five-layer co-extrusion films.

Agricultural Films: Mulch films, irrigation systems, and greenhouse covers.

Consumer & Industrial Use: Transparent parts and industrial components requiring high brightness and smooth finish.

Our Advantages

Our Factory was established in 2016 and is one of China’s leading manufacturers of functional masterbatches. We integrate R&D, production, and technical service to deliver reliable plastic material solutions worldwide.

Annual production capacity: 100,000 tons

Factory area: Over 60 acres with advanced twin-screw extruders

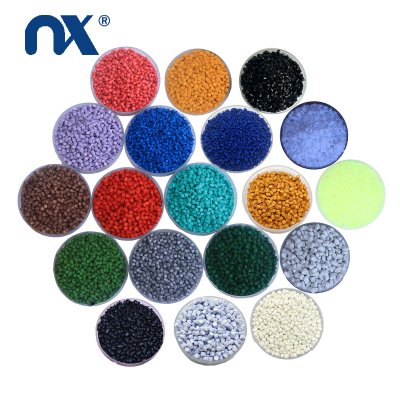

Main products: Na₂SO₄ filler masterbatch, CaCO₃ masterbatch, color masterbatch, black masterbatch, talc filler masterbatch, desiccant master batch

Applications: Blown film, injection molding, cable sheathing, geomembrane, lunch box, pipes, and woven plastic

Certifications: ISO9001, RoHS, FDA, Environmental & Occupational Safety Standards

Packaging & Delivery

| Packaging Type | Paper-plastic composite bags, PE valve bags, PE adhesive bags, transparent PE valve bags |

|---|---|

| Net Weight | 25 kg/bag |

| Package Size | 75 × 45 × 20 cm |

| Storage | Store in a dry, ventilated area away from direct sunlight |

We use professional and eco-friendly packaging materials to ensure safe and efficient delivery to all customers.

Environmental Benefits

The use of Na₂SO₄ filler masterbatch supports sustainability goals by reducing virgin resin usage, cutting production costs, and lowering carbon emissions. It maintains color and clarity even when mixed with recycled plastics, helping manufacturers move toward a circular economy.

FAQ

Q1: Are you a manufacturer or trading company?

We are a masterbatch manufacturer located in Dezhou, Shandong, specializing in masterbatch production since 2016.Q2: Can you provide samples?

Yes, free samples are available upon request.Q3: What payment terms do you support?

We accept T/T, L/C, and other international methods.Q4: How to store the masterbatch?

Keep sealed and store in a cool, dry, ventilated area.Q5: Do you offer technical support?

Yes, our engineers provide both online and on-site guidance to optimize your production.

Contact Us

If you are looking for a reliable filler masterbatch supplier, contact us :

Email: zina@nuoxinplastic.com | Phone: +86 186 6016 7636