Sodium Sulfate Filler Masterbatch

Product Advantages

Good compatibility: It has good compatibility with a variety of plastics such as PP, PE, PVC, etc. and can be widely used in the production of different plastic products.

Uniform dispersion:The unique production process makes sodium sulfate evenly dispersed in the plastic matrix, avoiding agglomeration and ensuring uniform performance of plastic products.

Enhanced plastic performance:Effectively improve the rigidity, hardness and dimensional stability of plastics, reduce deformation and warping of products, and extend product service life.

Reduced costs:Under the premise of ensuring product quality, we can reduce raw material costs, improve production efficiency, and create more profit space for enterprises.

High transparency:Sodium sulfate's unique refractive index and particle size distribution that are beneficial to optical properties have little impact on the transparency of the finished product.

Environmentally friendly and non-toxic:It complies with EU RoHS certification and can be used in food-related products.

High efficiency sodium sulfate filler masterbatch

Product Introduction

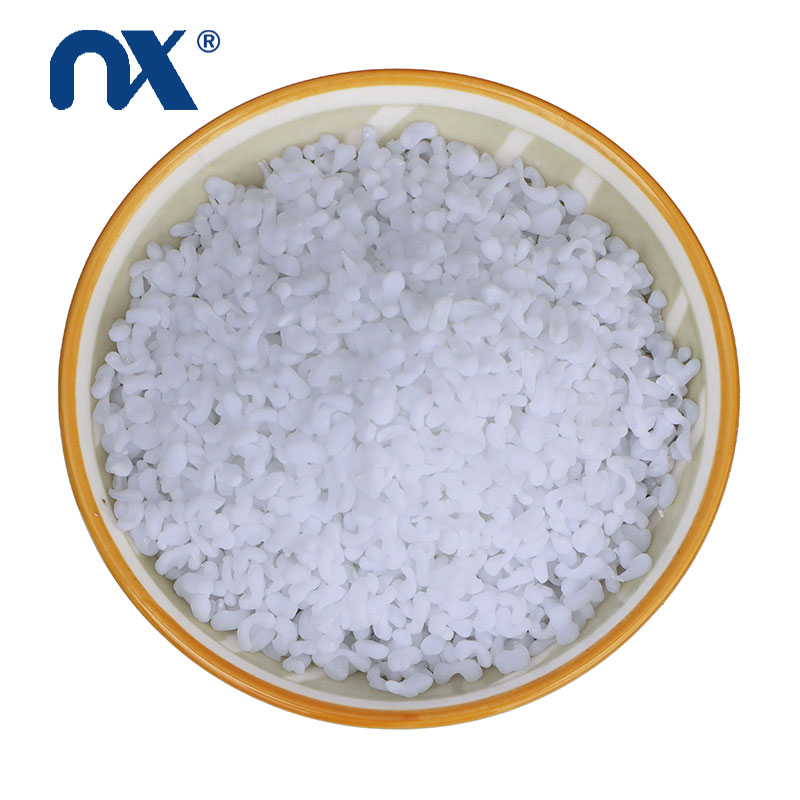

This sodium sulfate filler masterbatch uses nano-grade high-quality anhydrous sodium sulfate as the main raw material, and is made through special surface treatment and optimized combination with carriers and additives. The product has excellent compatibility, dispersibility and excellent light transmittance in polymer material systems such as PE/PP. It is a high-performance, low-cost, environmentally friendly functional masterbatch. It is widely used in the production of plastic products, such as plastic pipes, plates, films, etc. It is your ideal choice for improving product quality and optimizing production costs.

Product specifications

| Model | SN-106: Applicable to PE shopping bags, garbage bags, roll bags SN-103: Applicable to PE cast film, wrapping film, various industrial packaging films SN-102: Applicable to HDPE blown film, PE/PP blow molding,injection molding products |

| Particle size | 2-5mm |

| Reference ratio | 10%-50% |

| Color | white/transparent |

| Packaging | 25kg/bag |

| Applicable plastic types | PP, PE |

| Grade | general purpose |

| Brand | NUOXIN |

Preferential policies

● Sample testing: Free samples are provided, and you only need to pay for the shipping fee, so that you can experience the product quality first.

● Sample return discount: After purchasing samples, if you decide to purchase large quantities, you can use the sample return coupons given to you to deduct the corresponding amount, and the discount is visible.

Usage method

●Adding ratio: According to the specific requirements and performance indicators of plastic products, the general adding ratio is 10%-50%, and the specific adding amount needs to be determined by experiment.

●Mixing method: Mix the sodium sulfate filling masterbatch and the plastic raw material evenly according to the proportion, and high-speed mixer or twin-screw extruder and other equipment can be used for mixing.

●Processing technology: Process according to conventional plastic processing technology, such as injection molding, extrusion, blow molding, etc., without special adjustment of process parameters.

Factory Strength Display

Production Experience: 10 years of professional production experience, mature technology, stable quality.

Production Line: Equipped with 15 advanced product production lines, sufficient production capacity to meet the needs of large-volume orders.

Warehouse: 2,000 square meters of large warehouse, rich inventory, timely delivery, to ensure customer supply.

Technical R&D Team: Professional technical R&D team, continuous product innovation and process improvement, can provide customized solutions according to customer needs.

Related product recommendations

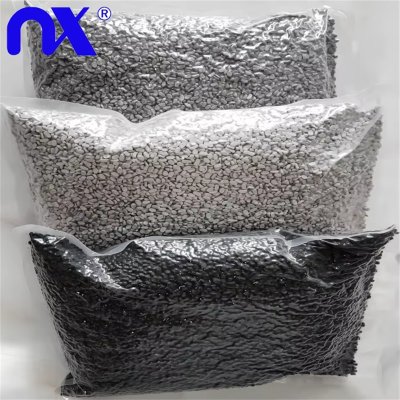

●Calcium carbonate filler masterbatch: used in combination with sodium sulfate filler masterbatch, it can further optimize the performance of plastic products and reduce costs.

●Black masterbatch: Carbon black concentration 5%-50%, suitable for the production of various plastic products

Customer Service and Contact Information

If you have any questions during non-online customer service hours, please feel free to contact us at any time through the above methods. We will serve you wholeheartedly.