Calcium Carbonate Filler Masterbatch Extrusion

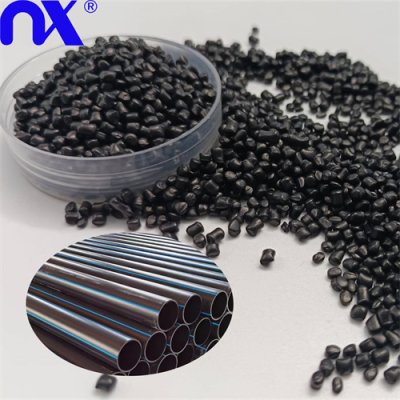

CaCO₃ filler masterbatch is a composite materials made from CaCO₃, primary polyethylene resin, and various dispersing plastic additives.

CaCO₃ filler masterbatch is a kind of cost-effective additive,it can enhance opacity, improve rigidity, and reduce production expenses for molded plastic products.

This filler is compatible with both virgin and recycled plastics materials and is commonly applied in manufacturing woven PP bags and PP ropes, with a typical blending ratio ranging from 5% to 50%.

Factory store for fast delivery and on time service

We can provide free samples within 10KG.

Support multiple payment methods: T/T, LC, DP, etc.

Product Description:

CaCO₃ filler masterbatch (calcium carbonate filler masterbatch) is a functional plastic modification material made with high-quality ground calcium carbonate (GCC) or light calcium carbonate (PCC) as the core filler, uniformly dispersed

and coated in a specific carrier resin (primarily polypropylene or polyethylene) through an advanced process. As an effective partial replacement for resin, it is widely used in various plastic processing techniques, especially injection molding. Through a scientifically formulated ratio (typical addition ratio is 10% to 50%), this masterbatch significantly reduces raw material costs while optimizing and improving multiple key properties of the final plastic product.

Product Paramenters

| Product name | Calcium Carbonate Filler Masterbatch |

| Carrier | PE/PP |

| Calcium carbonate content | 75%-85% |

| melt index | 5-40g/10min |

| density | 1.8-2.2g/cm3 |

| compatibility | PP/PE/PVC |

| Package | 25kg/bag |

Product Application:

For Woven Bags and Shopping Bags Usage

Cost Reduction: CaCO3 Filler masterbatch can Replace 30–50% of virgin PP,which can lower material costs by 25–40%.

Performance Enhancements:

Stiffness: CaCO3 Filler masterbatch can Increase flexural modulus by 40–80%, it can improve stackability and load-bearing capacity.

Opacity:When achieves <5% light transmission at 35% loading, it can protecting UV-sensitive contents .

Moisture Resistance: It can reduce water vapor transmission rate (WVTR) by 15–20% via filler-induced path tortuosity.

Save Cost Efficiency: when achieves 20–35% filler loading,it can cut PE consumption by 15–30%, reducing bag production costs.

Package and stock.

Calcium carbonate filler masterbatch is usually 25KG/bag. We have a lot of stock and can guarantee fast delivery.

Exhibition:

Nuoxin New Materials (shandong) Co., Ltd is a leading integrated manufacturer and global supplier in the masterbatch industry. We bring over a decade of expertise in research, development, and production. Nuoxin has a strong manufacturing foundation,which supported by advanced technology and strict quality control to ensure high-performance masterbatch solutions.

We have actively participated in top-tier masterbatch exhibitions worldwide, showcasing our innovations and strengthening our presence in the international market. We try our best to be excellence has earned us long-term partnerships with clients across various industries.

Our servie:

Commitment to Partnership, Not Just Transactions,we reject the "sell and disappear" approach. When you partner with Nuoxin, you join a dedicated community invested in your success.

Our Unwavering Support:

· 24/7 Human Expertise: Connect with real specialists—never automated systems.

· Rapid Response Guarantee: Receive detailed email replies within 12 hours.

· Transparent Logistics: Real-time shipment tracking from production to delivery.

· Science-Backed Collaboration: Technical guidance on formulation optimization and application.

· Satisfaction Assurance: If expectations aren’t met, we resolve it immediately—no justification needed.

Why NuoxinStands Apart in Manufacturing & Supply:

· Integrity-Driven Production: We formulate only scientifically validated, purpose-driven solutions.

· Listening-First Philosophy: Your challenges shape our R&D and process innovations.

· Mastery of Plastics production: Decades of material expertise translate into performance you can measure.

· Human-Centered Impact: We prioritize how our products enhance well-being—yours and your customers'.