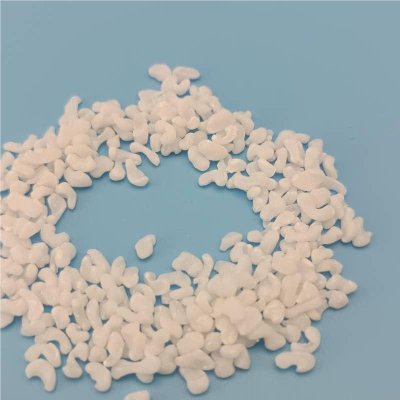

CaO-Based Desiccant Masterbatch

✔ Chemical drying effect

✔ Easy to mix, no extra step

✔ Works with most thermoplastics

✔ Good thermal stability

✔ No harmful by-products

Overview

Many plastic manufacturers especially those using recycled resins often struggle with moisture issues during processing. Whether it's unwanted bubbles in film or streaks on injection parts, excess water can disrupt production and hurt product quality.

Our calcium oxide-based desiccant masterbatch tackles this problem at its root. Instead of relying on costly drying systems, processors can simply blend this additive directly into the resin mix, letting the CaO component absorb moisture during melt processing.

Why Use It

Permanently removes moisture through chemical reaction (CaO + H₂O → Ca(OH)₂)

No drying equipment required, simplifying production

Both recycled and virgin plastics can be used

Processing issues such as bubbles, streaks, and warping are significantly reduced

Reduces costs by reducing scrap

Processing Applications

Injection Molding: Use in PA, ABS, or recycled PP to prevent streaks, poor flow, or short shots.

Blown Film: In LDPE or LLDPE films, it improves transparency and avoids bubble instability.

Extrusion: Keeps moisture-sensitive profiles, pipes, and sheets free from lines and roughness.

Blow Molding: Achieves smoother wall thickness and better appearance in bottles and containers.

Recycled Plastic Use: Helps manage moisture from post-consumer or industrial plastic scrap.

Features at a Glance

✔ Chemical drying effect

✔ Easy to mix, no extra step

✔ Works with most thermoplastics

✔ Good thermal stability

✔ No harmful by-products

Why Work with Us

Over 10 years in masterbatch manufacturing

Large monthly output for bulk orders

In-house lab for formula adjustment and testing

Reliable QC for each production batch

Global logistics and export documents available

Packaging & Storage Tips

Use standard 25 kg bags with moisture-proof liners

Keep sealed before use to prevent early reaction

Shelf life: 6–12 months in dry indoor storage