Red Color Masterbatch

1. Customizable colors and sample testing available.

2. Multiple carrier options: PP, PE, ABS, PET, PLA.

3. Complies with various international environmental standards, including FDA and ROHS certifications.

4. Thousands of samples in stock, free for testing; you only need to pay for shipping.

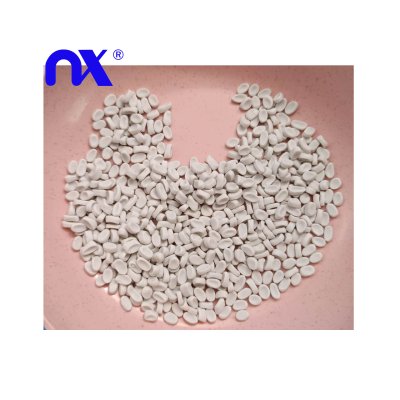

Bright and Stable Color

NUOXIN’s red color masterbatch presents pure, bright, and durable red, ensuring the uniform color of plastic products. It disperses evenly in the plastic matrix, avoiding issues like color spots or dots. With excellent compatibility across various plastic resins, it is suitable for different processing methods. Easy to operate and measure, it allows precise control over dosage. During both processing and usage, it maintains excellent stability without affecting the other properties of the plastic.

Physical Characteristics

| Index | Numerical Value |

|---|---|

| Carrier | PE/PP/ABS/PET/PLA/PETG |

| Carbon Black Content | 10% - 50% |

| Melt Index | 10 - 30 g/10min |

| Compatibility | PE/PP... |

| Color | Red |

Application

Red Color masterbatch is widely used and can be customized according to customer samples. It is suitable for blow molding, injection molding, wire drawing, tube drawing, and other plastic processing techniques.

Red is a common color in plastic products. Consequently, red masterbatch is also a popular choice. Nuoxin's red masterbatch offers vibrant, uniform coloring, and excellent dispersion. To achieve excellent coloring results, you need high quality pigments. We use only high quality inorganic and organic pigments in our production process. Combined with advanced twin-screw extrusion technology, the color powders is evenly and thoroughly encapsulated within the carrier resin. This ensures minimal color variation from per batch , significantly reducing color variations in your product.

If you have extremely high requirements for product color matching, the best option is to mail us a sample or color swatch. We'll customize the color based on the sample or swatch. Whether you need a vibrant red, a warm orange-tinged red, or a cool bluish red, we can ensure colour fastness even though meeting your gloss and transparency requirements.

Our red masterbatch can be used in a variety of plastic product processing applications, including film blowing, injection molding, wire drawing, and tubing extrusion. For example, film for blown plastic bags and packaging bags requires uniform color. Injection molding of toys, household items, or automotive parts requires stable color and a smooth surface. Wire drawing and tubing extrusion ensure color stability and surface smoothness even at high production speeds.

This masterbatch exhibits excellent compatibility with PE and PP resins. We can also customize color masterbatches for PET, PLA, and ABS carriers without affecting the physical properties of the finished product. It also offers strong heat, weather, and chemical resistance, making it suitable for long-term use and outdoor environments. Its combination of consistent quality, flexible customization, and excellent cost-effectiveness makes it an ideal choice for long-term partnerships with numerous plastic product manufacturers.

Packing and Delivery

Standard Packaging: Each batch of masterbatch is packed in high-strength, moisture-proof woven bags with an inner PE liner to prevent contamination and moisture absorption. Standard weight: 25 kg/bag.

Dimensions: Single package size: 75 cm × 45 cm × 10 cm; weight: 25kg.

Custom Packaging Service: We offer personalized packaging solutions based on customer requirements, including:

Printing customer’s logo, brand name, or color codes on the bag for brand recognition.

Using eco-friendly recyclable packaging materials to meet environmental compliance in different markets.

Customized bag sizes or smaller weight packaging (e.g., 5 kg, 10 kg, 20 kg) for easier handling in specific applications.

Export-grade palletizing with stretch film wrapping for safer long-distance transportation.

Delivery Options: Flexible shipping solutions are available, including sea freight, air freight, and courier services. All goods are labeled with batch numbers for easy traceability and quality tracking.

Lead Time: Regular stock orders can be shipped within 3–5 working days. For customized formulations or colors, production time is usually 7–10 working days.

Protection During Transit: All shipments are handled with care to avoid damage from compression, moisture, or contamination, ensuring products arrive in perfect condition.

With this professional and customizable packaging approach, we not only ensure safe delivery but also help enhance your product image in the market.

Company Profile

Nuoxin New Materials (Shandong) Co., Ltd. is headquartered in Qingyun, Dezhou, Shandong, with a foreign trade office in Jinan, Shandong. Our main products include filler masterbatch, black masterbatch, color masterbatch, and desiccant masterbatch, widely used in lunch boxes, food packaging films, plastic stretch films, and bubble films. We export to over 50 countries and maintain long-term trade relationships with clients in Vietnam, Pakistan, and more.

FAQ

1. Delivery time?

We will ship within 20 days after receiving 30% of the order amount.

2. Is there certification?

Yes, our products have FDA 、Rohs and MSDS certification.

3. After-sales service?

Our professional technical team provides online guidance and support.