Calcium Carbonate Masterbatch vs Talc Masterbatch: Key Differences and How to Choose

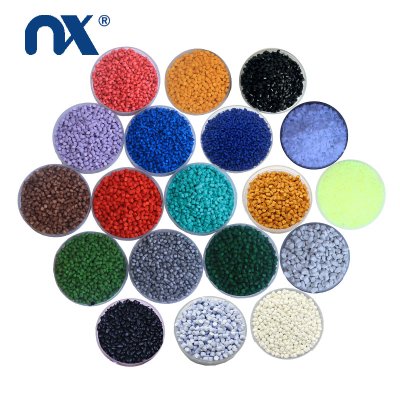

At Nuoxin, what are we selling? We're actually selling our customers' needs. So we constantly ask ourselves: What problems do our customers need us to solve? I believe price is a key concern for every manufacturer. Filler masterbatches play a vital role in the plastics industry. They not only enhance the performance of plastic products but also help reduce production costs. The most widely used are calcium carbonate and talc masterbatches, each with unique properties.

I've done some research.I have studied the raw materials, physical properties, processing performance, applications, pricing and market trends of these two masterbatches, and analyzed them. I hope it can be of some help to you.

1. Raw Materials and Physical Properties

Calcium Carbonate Masterbatch uses finely ground and Surface treatment calcium carbonate powder. The particles are generally micro/sub-micron in size and have a regular granular shape. High-grade calcium carbonate features high whiteness (>= 90%), which helps maintain bright and clean finishes. Additionally, it enhances stiffness and dimensional stability, reduce product deformation.

Talc Masterbatch is made from natural talc mineral that has been crushed, sieved, and surface-treated. Talc’s plate-like structure gives excellent lubricity, scratch resistance, and heat resistance. While it provides less stiffness than calcium carbonate, it improves surface feel and impact resistance.

Summary:

- Calcium Carbonate: Granular structure; increases stiffness, dimensional stability, and whiteness.

- Talc: Plate-like structure; improves lubricity, heat resistance, and surface smoothness.

2. Processing Performance and Equipment Adaptability

Processing requirements differ between the two:

Calcium Carbonate Masterbatch offers good flowability and works well with high-speed extruders and injection molding machines, making it suitable for high-output production.

Talc Masterbatch requires careful dispersion due to its lamellar structure. Poor mixing may lead to surface defects. It performs best on production lines with advanced mixing capabilities.

Case Example – Shandong, China: A film manufacturer using calcium carbonate masterbatch for shopping bags achieved 400 kg/hour output with stable operation. Later, to improve slip and scratch resistance, part of the calcium carbonate was replaced with talc masterbatch. Output slightly decreased, but customer satisfaction increased and product returns dropped by 20%.

3. Application Scenarios

Calcium Carbonate Masterbatch – Typical Uses

Shopping bags, garbage bags, woven sacks – increases stiffness, reduces deformation.

Pipes and profiles – improves dimensional stability and pressure resistance.

Appliance housings – maintains whiteness while increasing hardness.

Talc Masterbatch – Typical Uses

Automotive interior parts – improves surface smoothness and scratch resistance.

Home appliance casings – enhances tactile feel and reduces static dust attraction.

Heat-resistant plastic products – increases heat deflection temperature for high-temperature applications.

4. Product Parameter Comparison

| Parameter | Calcium Carbonate Masterbatch | Talc Masterbatch |

|---|---|---|

| Main Filler Material | Finely ground calcium carbonate (CaCO₃) | Natural talc powder (hydrated magnesium silicate) |

| Filler Particle Shape | Irregular granular / spherical | Plate-like lamellar |

| Average Filler Particle Size | 1–3 μm (customizable) | 2–5 μm (customizable) |

| Whiteness (ISO standard) | ≥ 94% | 88–92% |

| Density (g/cm³) | 2.6–2.8 | 2.7–2.9 |

| Thermal Resistance | Medium – suitable for general plastic processing | High – better for high-temperature applications |

| Mechanical Strength Effect | Increases stiffness and dimensional stability | Improves scratch resistance and impact strength |

| Surface Finish | Smooth but not as silky as talc | Very smooth and soft touch |

| Transparency Impact | Slightly reduces transparency (depending on dosage) | Slightly reduces transparency (similar effect) |

| Processing Ease | Excellent flowability, adaptable to high-speed extrusion | Requires careful dispersion for optimal results |

| Common Applications | Shopping bags, garbage bags, woven sacks, pipes, profiles | Automotive parts, appliance casings, heat-resistant products |

| Cost Level | Low – 8–15% cheaper than talc masterbatch | Medium – higher material and processing costs |

| Environmental Adaptability | Suitable for recyclable plastics and biodegradable blends | Suitable for recyclable plastics and high-heat applications |

5. Cost and Market Considerations

The price of calcium carbonate masterbatch is a little higher than that of talc filler masterbatch due to the abundance of raw materials and simpler processing. Although talc is more cost-effective, it is slightly higher expensive due to the higher quality of raw materials and more specialized processing.

For cost-sensitive manufacturers, calcium carbonate provides clear advantages. Meanwhile, for high-performance or premium products, the benefits of talc masterbatch—improved surface feel, scratch resistance, and heat performance—justify the investment.

6. Quality Control and Technical Support

When selecting a filler masterbatch, the following quality factors are crucial:

Uniform dispersion – prevents color variation and mechanical inconsistencies.

Low impurity content – reduces equipment wear and product defects.

Stable physical performance – ensures consistency between batches.

Nuoxin is a trusted supplier, we not only provides standard products but also offers formulation optimization.As a trustworthy supplier, Nuoxin not only provides standard products but also provides formula optimization. We can provide customers with customized masterbatch

7. Global Market Trends

Environmental regulations and circular economy initiatives are reshaping the market:

Southeast Asia and South America see rising adoption of calcium carbonate masterbatch in low-cost, high-volume products.

Europe and Japan favor talc masterbatch in high-end automotive and appliance markets, often combined with biodegradable resins.

Over the next five years, calcium carbonate masterbatch is expected to grow steadily in mid- to low-end applications, while talc masterbatch will maintain a strong position in high-performance segments.

8. Conclusion

Calcium carbonate and talc masterbatches each have their perks. Calcium carbonate is budget-friendly and super versatile, great for general use. Talc, on the other hand, shines when you need a smooth surface, high heat resistance, and stable dimensions for more specialized products. Which one to pick really depends on your product goals, customer expectations, production setup, and budget. Choosing carefully and fine-tuning the formula can save costs, boost product performance, and give you a competitive edge.