Moisture Absorber Masterbatch

Tailored CaO Content – Support customized calcium oxide levels to meet different drying requirements.

Flexible Granule Sizes – Offer various particle sizes for smooth processing across PE, PP, ABS, and more.

Custom Packaging Options – Provide moisture-proof bags, jumbo bags, or private-label packaging for branding.

Strong Factory Capacity – 15 advanced production lines, annual output 100,000 tons, with 500 tons in stock.

Reliable Global Supply – Certified ISO, ROHS, FDA, MSDS, and TDS, ensuring consistent quality and safe delivery worldwide.

What is Moisture Absorber Masterbatch?

Moisture Absorber Masterbatch, also called Desiccant Masterbatch/ Anti-Moisture Masterbatch, is a functional additive widely used in the plastics industry. It is usually made with calcium oxide (CaO) as the main active ingredient,combined with a polyethylene masterbatch or polypropylene carrier. This product is designed to absorb moisture during the plastic processing stage,solving problems caused by damp raw materials.

Many recycled plastics\ fillers and hygroscopic resins contain moisture. This moisture causes bubbles, holes, silver streaks, and surface roughness. Moisture Absorber Masterbatch removes the excess water during production. Manufacturers can get smooth and high-quality products. No extra drying equipment is needed.

Why Plastics Need Anti-Moisture Masterbatch

Plastic raw materials, especially recycled polyethylene (PE), polypropylene (PP), and other hygroscopic resins, often absorb water during storage and handling. This moisture content becomes a major issue during processing. When the material is heated in the extruder or injection molding machine, the moisture turns into vapor. The vapor forms bubbles inside the product or causes weak spots in the surface.

Traditional drying methods involve expensive machines and high energy consumption. Not every manufacturer can afford such systems.Anti-Moisture Masterbatch provides a simple solution. By mixing the masterbatch directly with raw resin, moisture is absorbed in-situsaving both time and costs.

Key Benefit: It allows plastic processors to work with recycled and damp raw materials without investing in drying machines.

Technical Specifications

| Parameter | Value |

|---|---|

| Carrier Resin | PE or PP |

| Active Ingredient | Calcium Oxide (CaO) |

| Moisture Absorption Capacity | 20% of its own weight |

| Recommended Dosage | 2% – 5% depending on raw material condition |

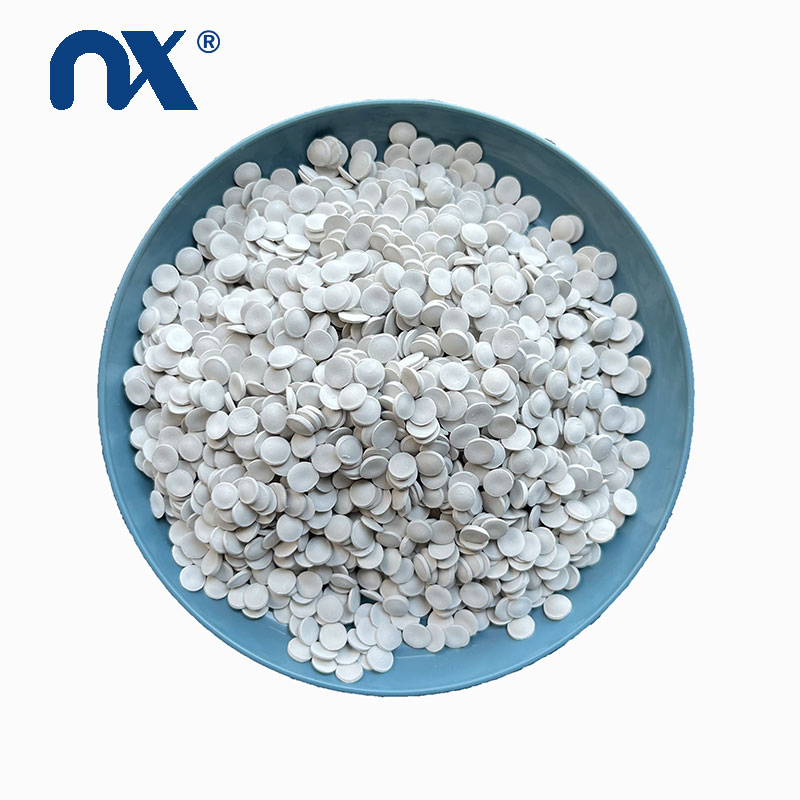

| Appearance | White or off-white pellets |

| Certifications | ISO, ROHS, FDA, MSDS, TDS |

| Packing | 25kg moisture-proof bags |

Main Functions and Advantages

Moisture Absorption: Removes free water and bound water during processing.

Defect Prevention: Reduces bubbles, cracks, and flow marks in plastic products.

Improved Surface Quality: Ensures glossy and smooth finishes without visible defects.

Higher Productivity: Eliminates pre-drying, which saves production time.

Cost Reduction: Avoids the need for drying machines and reduces power consumption.

Resin Compatibility: Works well with PE, PP, ABS, PS, recycled materials, and filler-loaded plastics.

Improve product yield

Applications of Moisture Absorbent Masterbatch

Moisture Absorber Masterbatch is widely applied in different industries where plastic processing is required.Common application areas include:

Film Blowing: For PE and PP films used in packaging, agricultural films, and shopping bags.

Injection Molding: Used in household products, automotive parts, toys, and containers.

Extrusion: Applied in pipes, sheets, and profiles where moisture defects can damage strength.

Recycled Plastics: Essential in reprocessing waste plastics where moisture content is high.

Because of its compatibility with polyethylene masterbatch and polypropylene systems, this product is one of the most versatile additives in the plastic compounding industry.

How It Works

The active component in Moisture Absorber Masterbatch is calcium oxide. This compound reacts with moisture and forms stable calcium hydroxide.During the plastic processing stage, the masterbatch absorbs both free moisture and chemically bound water. This prevents the water from turning into vapor.

The result is a stable melt flow, stronger final products, and defect-free surfaces. Since the reaction happens inside the extruder or molding machine,there is no need for extra drying steps.

Comparison by Calcium Oxide Content

| CaO Content | Moisture Absorption | Recommended Dosage | Typical Applications |

|---|---|---|---|

| 50% | Moderate moisture absorption | 3% – 5% | General PE films, PP woven bags |

| 65% | High moisture absorption | 2% – 4% | Injection molding, blow molding products |

| 75% | Very high moisture absorption | 1% – 3% | High-precision extrusion, high-grade packaging films |

| 80%+ | Maximum absorption, rapid effect | 1% – 2% | Moisture-sensitive engineering plastics, export packaging |

Customized Service

We understand that different industries and applications require unique solutions. To meet these needs, we provide full customization options for ourMoisture Absorber Masterbatch.

Customized CaO Content: Adjust calcium oxide percentage based on product requirements, ranging from 50% to 80% or higher.

Different Particle Sizes: Provide masterbatch with various granule sizes to ensure smooth processing in PE, PP, ABS, or other polymers.

Custom Packaging: Offer flexible packaging options, such as 25kg moisture-proof bags, jumbo bags, or private-label designs for branding needs.

With our strong R&D capability and strict quality control, we deliver tailor-made solutions that match customer production processes. Whether you need desicant masterbatch for extrusion, injection molding, or export packaging, our customized services guarantee efficiency and consistent results.

Case Studies and Customer Feedback

Case 1: India – Film Packaging Factory

A film manufacturer in India used recycled polyethylene mixed with calcium carbonate filler. Their films often showed bubbles and surface roughness. After adding 3% of our desiccant Masterbatch,the films became smoother and stronger. Production efficiency improved, and customer complaints dropped sharply.

Case 2: Vietnam – Injection Molding

A plastic household products factory faced silver streaks and cracks due to moisture in PP resin. They tested our masterbatch at 2.5% addition rate. The defects disappeared, and product quality met export standards.

Case 3: Middle East – Recycled Plastics

A recycling company in the Middle East processed post-consumer plastics with high moisture contentDrying costs were too high. By adding 5% Moisture Absorbent Masterbatch, they skipped drying and achieved stable production.This reduced energy consumption and saved labor.

Global Market Trends

The demand for Moisture Absorber Masterbatch is growing worldwide. The rise of recycling and sustainable packaging increases the need for anti-moisture solutions. Many companies in North America, Europe, and Asia now use pemasterbatch and polypropylene-based solutions to process mixed and damp raw materials.

With the expansion of e-commerce, agriculture, and food packaging industries, film manufacturers require more reliable processing aids. Anti-Moisture Masterbatch supports this demand by improving efficiency and reducing costs. It also helps businesses remain competitive by lowering energy usage and waste.

Why Choose NUOXIN desiccant Masterbatch?

High Absorption: Removes up to 20% of its weight in water.

Consistent Quality: Every batch is tested before delivery.

Fast Delivery: 500 tons of stock ready for shipment.

Certified Safe: Meets ISO, ROHS, and FDA standards.

Global Supply: Exported to India, Vietnam, Thailand, Canada, and more.

Conclusion

Desiccant((CaO-base) ) Masterbatchis an essential additive in the plastics industry. It prevents moisture-related defects, improves processing, and reduces production costs. Whether for film blowing, injection molding, extrusion, or recycling, it provides practical and reliable results.

As a trusted manufacturer of pe/pp masterbatch and filler masterbatch, NUOXIN supplies high-quality, certified productsto customers worldwide. With strong stock, fast delivery, and proven case studies, we are ready to support the growing demand for anti-moisture solutions.