Plastic Desiccant Masterbatch

Improve product quality: By effectively removing moisture, ensure that the finished plastic product is bubble-free and flawless, and improve the appearance and physical properties of the product.

Simplify the production process: The desiccant masterbatch is in a pre-mixed form, easy to use, and does not require additional processing steps, which improves production efficiency.

Cost-effectiveness: Reduce processing defects and rework costs caused by moisture, help customers improve production efficiency and reduce waste.

Widely adaptable: Applicable to a variety of common plastic resins, and can maintain excellent moisture absorption at different processing temperatures.

Product Name: Plastic Desiccant Masterbatch

Main Ingredient: Calcium Oxide

Product Overview

Plastic Desiccant Masterbatch (Calcium Oxide) is a functional additive for moisture absorption, which is widely used in the drying of raw materials in plastic production. Its main ingredient is calcium oxide, a chemical with strong hygroscopicity, which can effectively absorb moisture from raw materials during plastic processing. The presence of moisture in plastic processing can lead to unstable product quality, surface defects, and molding difficulties. The use of desiccant masterbatch can significantly improve these problems and improve processing efficiency and product quality.

Product Features

Strong Hygroscopicity

Calcium oxide is a strong hygroscopic material that can quickly absorb moisture from air and plastic raw materials. It is especially suitable for the drying process of thermoplastics such as PE, PP, and PVC. It can significantly reduce the impact of moisture on the plastic processing process, such as reducing blisters, surface defects, and molding difficulties.

Improve plastic processing stability

By absorbing moisture, the influence of moisture in plastic is reduced, the uniformity and processing stability of molten plastic are ensured, and the physical properties of the product, such as strength, toughness, transparency, etc., are improved.

Reduce processing defects

Moisture is a common problem in plastic processing, especially in injection molding, extrusion, blow molding and other processes, moisture may cause defects such as bubbles, flow marks, cracks, etc. The use of desiccant masterbatch can effectively prevent these problems and improve the yield and processing efficiency.

Strong adaptability

This product is compatible with a variety of common plastic resins (such as polyethylene PE, polypropylene PP, polyvinyl chloride PVC, etc.), and can maintain a stable moisture absorption effect under a wide range of processing temperatures.

Convenient use

As pre-mixed particles, desiccant masterbatch can be directly added to plastic resins for use, without the need for additional complex processes (such as drying raw materials), simplifying the production process and improving production efficiency.

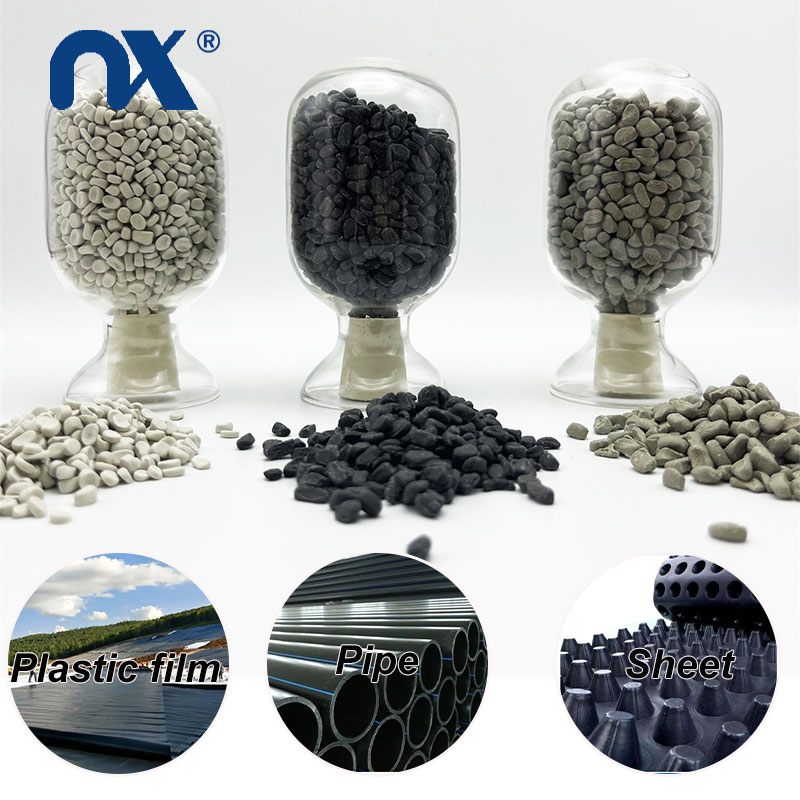

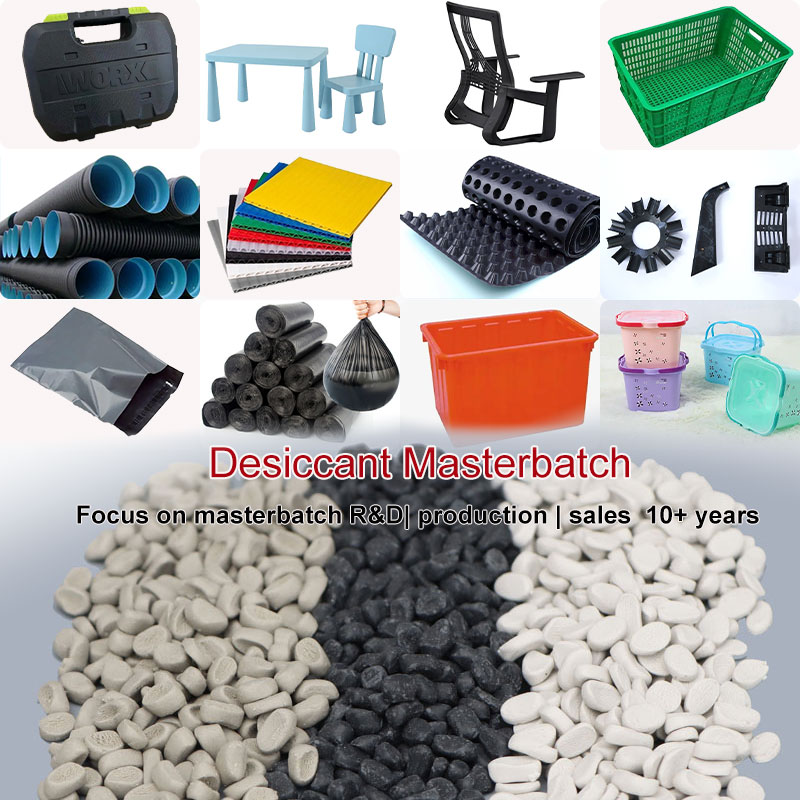

Product application

Plastic processing: injection molding, extrusion, blow molding and other processes, such as: plastic bags, garbage bags, parcel bags, plastic furniture tables and chairs, daily necessities, drain pipes, drain boards, hollow containers and other plastic products.

Usage

Dosage recommendation: It is usually recommended to add desiccant masterbatch to plastic raw materials at a ratio of 1%-3%. The specific ratio can be adjusted according to the moisture content of the raw materials and processing requirements.

Product packaging

Our Advantages

Production Capacity:15 production lines, daily output 200 tons, can achieve 7 days fast delivery

Production Equipment:8 types of production equipment, can provide customized production for customers

Factory scale:The factory covers an area of 6,000 acres and can accommodate 2,000 tons of inventory. Urgent orders can also be delivered super quickly.

High-quality raw materials: high-quality raw materials are used, and each batch of production will be inspected for product quality to ensure the stability of product quality.

Sample service: Provide customers with free samples for testing, and purchase only after they are satisfied with the test, so that customers can rest assured and satisfied.

Calcium oxide desiccant masterbatch is an efficient hygroscopic plastic additive that absorbs moisture from plastic raw materials to improve various problems caused by moisture in plastic processing. It can significantly improve the quality and stability of the product, reduce defects in the production process, and reduce scrap rate and rework costs. Choosing our desiccant masterbatch will help improve your production efficiency and product quality.