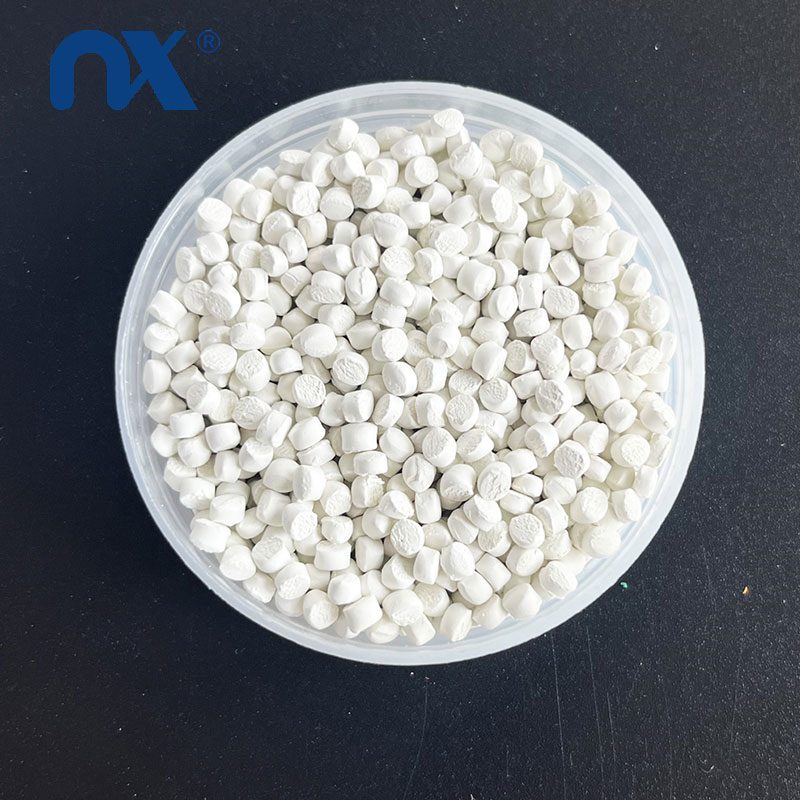

White Masterbatch

Brilliant whiteness—high TiO₂ load for strong opacity.

Excellent dispersion—no streaks, no spots on finished parts.

UV and weather resistance—reduces yellowing outdoors.

Thermal stability—suitable for high-temperature processing.

Low dust handling—clean, safe pellet form.

Cost efficient—high covering power reduces addition rate.

Product Overview

White Masterbatch is one of the most widely used plastic colorant masterbatch products. It is made by mixing high-quality titanium dioxide (TiO₂), polymer carriers, and suitable additives. The result is a masterbatch with strong hiding power, brilliant whiteness, and excellent dispersion.

Many industries need white master batch for plastic applications. Packaging, household items, films, and injection products all depend on stable and bright color performance. Because of this demand, many white masterbatch manufacturers around the world continue to develop advanced grades to meet customer requirements.

Our White Masterbatch stands out in the plastic colorant masterbatch market. It offers consistent quality, reliable performance, and strong compatibility with multiple resin systems. Customers can use it to create high-quality plastic products with clear white appearance and long-lasting brightness.

Product Features

Brilliant whiteness—High titanium dioxide content provides strong opacity.Surfaces look clean, bright, and pure.

Excellent dispersion—Pigments are distributed evenly in the resin.No streaks or spots appear in the final product.

UV and weather resistance—Protects plastics from yellowing under sunlight.Ideal for outdoor applications like films and containers.

Thermal stability—Designed for high-temperature processing.Prevents degradation during extrusion and injection molding.

Low dust handling—Only a small addition is needed.Saves cost while ensuring high opacity.

Cost efficient—Suitable for PE, PP, PS, ABS, and other polymers.Works well in film, molding, and extrusion processes.

Typical Specifications

| Item | Typical Value |

|---|---|

| Carrier Resin | PE / PP (customizable) |

| TiO₂ Content | High (varies by grade) |

| Melt Flow Index (MFI) | 1 - 30 g/10min (custom) |

| Appearance | White granules / pellets |

| Recommended Addition | 2% - 5% (depending on target opacity) |

| Packaging | 25kg bag (moisture-proof) |

Applications

White Masterbatch has broad use across many sectors. Below are common application areas and benefits:

Films & Packaging

Used in shopping bags, garbage bags, shrink films, and food wraps. It improves opacity and helps hiding printed text. The white tone enhances product look on shelf.

Injection Molding

Used for containers, lunch boxes, houseware, and toys. It delivers smooth surface and high whiteness for consumer products.

Pipes & Profiles

Provides bright appearance for pipes and profile products. It helps maintain color stability under sunlight.

Blow Molding

Ideal for bottles, caps, and hollow parts. Good dispersion helps wall thickness uniformity and reduces defects.

Textiles & Nonwovens

Brightens fibers and nonwoven products. Works well for applications that need high whiteness and low discoloration.

Why Choose Our White Masterbatch

Professional Manufacturing

We are among the leading white masterbatch manufacturers in China. Our factory has modern production lines and strict quality control. Every batch is tested before delivery to ensure stability.

Certified Quality

Our products comply with ISO, ROHS, FDA, MSDS, and TDS. This ensures safety for food contact packaging and other sensitive uses.

Custom Solutions

We support custom color matching and formulation adjustment. Clients can send samples, and we will provide testing and trial production.

Global Market Supply

Our white master batch products are exported worldwide. Customers in Asia, Europe, Africa, and America trust our stable supply and competitive pricing.

Fast Delivery

We keep regular stock and can ship within 24 hours. Large orders are delivered quickly because of our 100,000 tons annual production capacity.

Processing Benefits

Pre-dispersed pigment reduces mixing time.

Lower chance of dust and respiratory exposure.

Improved filter life and less screen clogging.

Lower scrap rate from color defects.

Stable melt flow helps consistent molding.

Quality & Safety

We follow strict quality routines. Raw materials are inspected on arrival. Production follows defined procedures. Finished batches go through multiple tests. We measure TiO₂ dispersion, MFI, whiteness index, and moisture. We keep traceable records for every lot. The product meets ISO standards. We supply ROHS, FDA, MSDS, and TDS documentation when required. These controls make the masterbatch suitable for sensitive uses.

Packaging & Logistics

Standard packing is 25 kg per moisture-proof bag. We offer palletized loads for larger orders. Bags use inner PE liners to prevent moisture ingress. We can pack to customer specs. Shipping options include sea freight, air freight, and express. We handle export documentation and pre-shipment inspection on request. Our warehouses hold regular stock to speed delivery.

Company Profile

Nuoxin New Materials is a dedicated masterbatch manufacturer. We operate modern extrusion lines. Our factory area is large and production capacity is high. We supply global customers in packaging, automotive, construction, and consumer goods. Our team provides technical support for formulation, feeding, and processing. We help customers scale from sample runs to full-scale production.

We aim to be a reliable partner in the plastic colorant masterbatch market. We focus on product stability, timely supply, and responsive service.

Sample & Custom Development

We offer sample programs. Send us your resin type and target opacity. We will prepare trial masterbatch for your testing. We also provide bespoke grades. You can request special carrier resin, specific MFI, or tailored additive packages. Our lab supports color trials and performance testing to ensure the product meets your needs before mass production.

Customer Case Study

A food packaging customer faced uneven whiteness with recycled resin. They needed stable white films for printed labels. We supplied a custom white masterbatch formulated to improve hiding power on recycled blends. After trial runs, film opacity improved. Printing adhesion and surface gloss also improved. The customer reduced rejects and increased throughput.

Other Recommended Products

Black Masterbatch — high opacity black colorants.

Color Masterbatch — custom color solutions for brand needs.

Filler Masterbatch — calcium carbonate and talc options to reduce cost.

Desiccant Masterbatch — moisture control in processing.

FAQ

Q1: What addition rate do you recommend?

A1: Typical addition is 2%–5%. The final rate depends on desired opacity and product type.

Q2: Can you supply food-grade white masterbatch?

A2: Yes. We offer FDA-compliant grades for approved food-contact applications.

Q3: Do you support custom carrier resins?

A3: Yes. We can match PE, PP, PLA, ABS carriers and tailor MFI as needed.

Q4: Are samples free?

A4: We provide sample quantities for testing. Shipping costs are usually charged to the buyer for express delivery.

Conclusion

White Masterbatch is one of the most important products in the plastic colorant masterbatch industry. It combines strong opacity, bright whiteness, and reliable dispersion. With advanced production technology and strict quality control, our white master batch products deliver consistent results for many applications.

As one of the trusted white masterbatch manufacturers, we are committed to providing stable supply, professional support, and cost-effective solutions for the global market. Whether you need standard grades or customized formulations, we can meet your requirements with high-quality products and quick service.