Yellow Masterbatch Color Sheet and Pipe Injection Molding

Great dispersibility: Yellow masterbatch spreads evenly in plastic substrates. It ensures consistent color in finished products.

Good color stability:Yellow masterbatch resists light, weather and oxidation. It won’t fade or discolor easily.

Keeps a vibrant look for long:Less pigment pollution. Uses nanocomposite tech and other manufacturing methods. Reduces pigment usage.

Cuts down environmental pollution from pigment dust.

Flexible MOQ. Offers various minimum order quantities, like 25 kg. Meets different customer needs.

Large stock.:Has a full product range. Large inventory. Enables fast delivery.

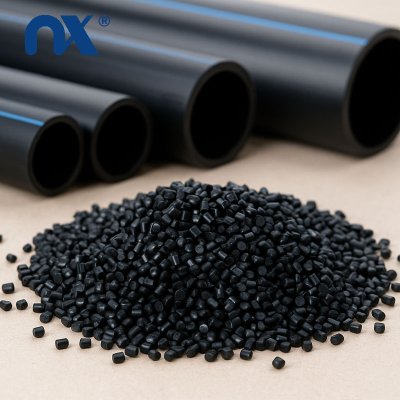

Product portrayal

Our product delivers a pure, bright, and long-lasting red hue, ensuring consistent color in plastic products. It disperses evenly within the plastic matrix, preventing issues like color spots and dots. With excellent compatibility across various plastic resins, it is suitable for different types of plastic processing. Easy to handle and measure, it allows for precise control over color addition. During processing and use, it maintains stability without compromising the other properties of plastic products.In addition to yellow masterbatch, we also have red, purple, blue, green, brown and white

Physical Characteristics

Application

Yellow masterbatch works well with common pipe materials like PE, PP and PVC. It spreads evenly when injection molding. No delamination or cracking from compatibility issues. Keeps pipe structure stable.

Uniform, stable color. Yellow masterbatch has strong tinting and good dispersibility. Injection-molded pipes have even color. No discoloration or specks. Makes pipes look better, higher quality.

Meets identification needs. Yellow is often a warning color in industry. It helps tell apart uses (e.g., gas pipes, specific industrial pipes). Yellow masterbatch makes standard yellow precisely. Gives clear functional ID to pipes.

Great weather resistance. Outdoor pipes face sun, wind, rain. High-quality yellow masterbatch resists light and weather well. Fights UV aging. No discoloration or brittleness after long use. Extends pipe life.

High-temp and chemical stability. In hot water pipes, industrial fluid pipes, etc. Pipes meet high temps or chemicals. Yellow masterbatch resists high temps and chemicals. Works with pipe base material. Ensures stable performance in complex environments.

Good processing flowability. Its melting temp fits pipe injection molding. Adding it doesn’t affect melt flow. Makes mold filling smooth. Reduces bubbles, sink marks, etc. Improves pipe molding yield.

Lower processing costs. Yellow masterbatch colors efficiently. A small amount gives desired color. Compared to using pigments directly, it cuts material waste. Prevents pigment dust from dirtying the workshop. Reduces cleaning and environmental disposal costs.

Our Advantage

Packing and Delivery

The net weight of a 1.25kg/bag is 25kg, with a tolerance of ±0.1kg, in compliance with industry measurement standards. The net weight of a ton bag is typically 1000kg, with a tolerance of ±0.5kg. Custom specifications are also available.

2. Packaging typically uses a composite bag with an inner layer of PE film and an outer layer of kraft paper, or a pure PE woven bag. Ton bags use high-strength PP woven fabric and can be equipped with a moisture-proof inner film upon request.

3. They are heat-sealed or seam-sealed, with a top lifting ring and a bottom discharge port for easy handling and unloading.

4. They are suitable for small and medium-sized purchases (monthly demand of a few to dozens of tons), while ton bags are suitable for large-volume purchases (monthly demand of dozens of tons or more).

5. They are easy to handle, unpack, and load, making them suitable for small and medium-sized processing plants without automated equipment. Ton bags require forklifts and other equipment, making them suitable for automated production lines. 6. Easier to manage and distinguish between products in small batches of multiple products, reducing the risk of mix-ups. Ton bags are suitable for large-scale, continuous production of a single product.

7. High procurement flexibility and minimal capital investment. Ton bags reduce unit transportation and packaging costs, making them suitable for long-distance transportation or export.

Customer's good feedback

Customer Visit

Customers from around the world are visiting our masterbatch production workshops to closely observe the entire process, from raw material screening and mixing to extrusion and pelletizing. From the precise operation of the automated production lines, to the rigorous testing of every sample in the quality control lab, to the neatly organized storage of 25kg standard bags and ton bags in the warehouse, our transparent production environment makes our promise of "high-quality masterbatch" visible and tangible.

The customers' focused gaze reflects their concern for product stability and their anticipation for collaboration. Our factory is more than just a production site. It is also a vital platform for deep interaction with our customers. It includes technical discussions. It involves precise matching of needs. It covers on-site inspections. It supports the building of long-term, trusting relationships. This two-way exchange is key. It drives our continuous improvement. It reinforces our unwavering commitment to quality. We sincerely invite partners to visit us. Come to gain a deeper understanding of our strengths. Let us collaborate to create value together.