Black Masterbatch Shandong Nuoxin Plastic

We produce over 100,000 tons per year with ready stock for 24-hour fast delivery.

All products are certified by ISO, RoHS, FDA, MSDS, and TDS.

We offer OEM & ODM services, including color matching and formula customization.

Each batch is triple-checked to ensure a 99.99% qualification rate.

Our masterbatch delivers high brightness, UV resistance, and excellent dispersion for stable performance.

Join our global distributor network and earn attractive commissions while growing your local market.

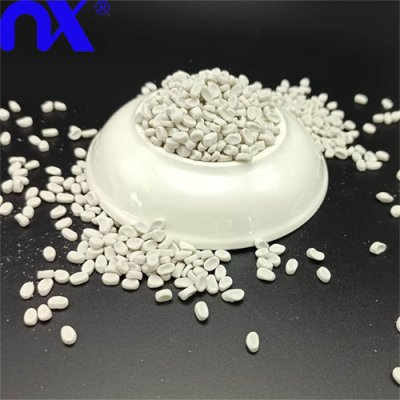

Black Masterbatch

Our Black Masterbatch is specially developed using a PE/PP/PVC/ABS carrier blended with premium carbon black.

It provides rich, deep black color with excellent dispersion, high coverage, and reliable processing stability.

This product is widely used in blown film, injection molding, pipes, and packaging materials, meeting the needs of both industrial and consumer-grade products.

We also offer customized grades such as film-blowing, food-grade, general-purpose, sanitary, and functional black masterbatch.

🎯 What Buyers Care About Most

We understand that customers choose a black masterbatch based on five key factors.

Here’s how our product meets all of them perfectly:

1️⃣ Deep Color & Strong Coverage

Made with high-quality carbon black, our masterbatch gives a solid, uniform color.

It effectively hides the base resin shade and maintains a consistent black finish, whether matte or glossy.

2️⃣ Excellent Compatibility & Dispersion

The formulation ensures smooth blending with both PP and PE resins.

No streaks, no uneven tones — only uniform, high-quality color throughout your final products.

3️⃣ Stable Processing Performance

Our masterbatch is designed for easy processing during blown film, extrusion, and injection molding.

It provides stable melt flow, good heat resistance, and no migration or color bleeding during production.

4️⃣ UV Resistance & Weatherability

For outdoor products, UV protection matters.

The black masterbatch absorbs ultraviolet light, preventing fading and extending the lifespan of pipes, films, and containers used outdoors.

5️⃣ Cost Efficiency & Compliance

With 5%–50% carbon black content, only a 1%–4% addition is needed to achieve a rich black tone.

This helps reduce resin use and overall production cost.

It also meets FDA and RoHS standards, ensuring safety for food-grade and eco-friendly applications.

🧩 PVC Masterbatch Series — Black & Color Options

In addition to PP/PE masterbatch, we also produce PVC Black and Color Masterbatch, designed for extrusion, injection molding, and cable manufacturing.

Our PVC masterbatch is formulated with high-quality pigments and compatible plasticizers to ensure excellent heat stability, dispersion, and color consistency.

Whether you need deep black for PVC pipes or bright, stable colors for profiles, wires, or sheets, our products deliver smooth processing and long-lasting performance.

Key Benefits:

Available in black and full-color ranges

Excellent heat resistance and lightfastness

Compatible with both soft and rigid PVC

Custom color matching and formulation available

Ideal for PVC films, profiles, cables, and injection-molded parts

💡 With our PVC masterbatch, manufacturers can achieve vibrant, stable colors while keeping production efficient and environmentally safe.

⚙️ Product Advantages

| Advantage | Description |

|---|---|

| Premium Carbon Black | Deep, pure black tone with matte or glossy finish. |

| Uniform Dispersion | Consistent color with no streaks or spots. |

| Strong Coverage | Hides base resin color effectively. |

| Migration Resistance | No color bleeding or contamination. |

| Weather Resistance | Built-in UV absorber for outdoor use. |

| Cost-Effective | Low dosage required for deep color. |

| Environmentally Safe | FDA and RoHS compliant for safe applications. |

🌍 Applications

Blown film: garbage bags, agricultural films, express bags

Injection molding: household products, industrial parts

Pipes and sheets: construction and irrigation applications

Packaging: food containers and flexible films

🏭 Factory Strength

| Advantage | Description |

|---|---|

| High Output & Fast Delivery | Annual capacity 100,000 tons, 500 tons in stock, and 24-hour dispatch available. |

| Strict Quality Control | Certified by ISO, RoHS, FDA, MSDS, and TDS. |

| OEM / ODM Service | Custom color matching, concentration adjustment, and private label production. |

| Six Key Features | High brightness, good transparency, UV resistance, moisture mark removal, excellent dispersion, toughness. |

| Exceptional Quality | 99.99% qualification rate with triple inspection from raw materials to finished products. |

📦 Packaging & Storage

Paper-plastic composite bag

Polyethylene valve bag

PE adhesive bag

Transparent PE valve bag

Net weight: 25kg/bag

Store in a cool, dry place, away from direct sunlight.

🤝 Distributor Partnership Program

We’re always open to new regional partners around the world.

As a Nuoxin distributor, you’ll enjoy:

Local pricing and fast supply

Full marketing and technical support

Free samples and color formulation guidance

Co-branding opportunities for mutual growth

💼 Let’s grow together with premium Masterbatch solutions!

❓ FAQ – About Black Masterbatch

Yes. We use premium carbon black with excellent dispersion, ensuring deep, solid color and no streaks or uneven shading.

Absolutely. Our masterbatch blends smoothly with PP, PE, HDPE, and LDPE, making it easy to use in film blowing, extrusion, and injection molding.

No. It has stable MFI and high heat resistance, ensuring smooth extrusion and clean processing without residue or die deposits.

Yes. It includes UV absorbers and weather-resistant additives that protect against fading and degradation outdoors.

Normally 1%–4% addition is enough. It provides strong color coverage while reducing resin use — a cost-effective and eco-friendly solution.

📞 Contact Us for Free Samples

Interested in testing quality before placing an order?

📩 Contact us today for free samples and technical support.

Our team can help you find the right formulation and optimize color performance for your application.