Global Recycled Plastic Pellet Market Expands Amid Quality Challenges

The global plastic industry is experiencing significant changes. Sustainability and recycling are now priorities for many countries. Governments encourage the use of recycled plastics. This shift drives strong demand for recycled plastic pellets. These pellets are widely used in packaging, piping, construction, and consumer products.

Despite growth, manufacturers face a major challenge: maintaining consistent quality. Variations in color, strength, and processing performance are common.

Why Recycled Pellets Are in Strong Demand

Government Regulations: Europe and Southeast Asia, and Africa,these all have rules for how much recycled plastic must be used. This keeps the demand for recycled pellets steady.

Cost Benefits: Recycled pellets are generally cheaper than virgin resins. Small and medium manufacturers use them to reduce production costs without sacrificing output.

Environmental Awareness: Consumers and brands are increasingly eco-conscious. Products made with recycled plastics are preferred.

Industrial Growth: The construction and infrastructure sectors in emerging markets rely heavily on recycled pellets.

Challenges in Recycled Pellet Quality

Recycled pellets come from mixed sources. Discarded plastic products, industrial scrap, and imported materials all contribute. These variations cause:

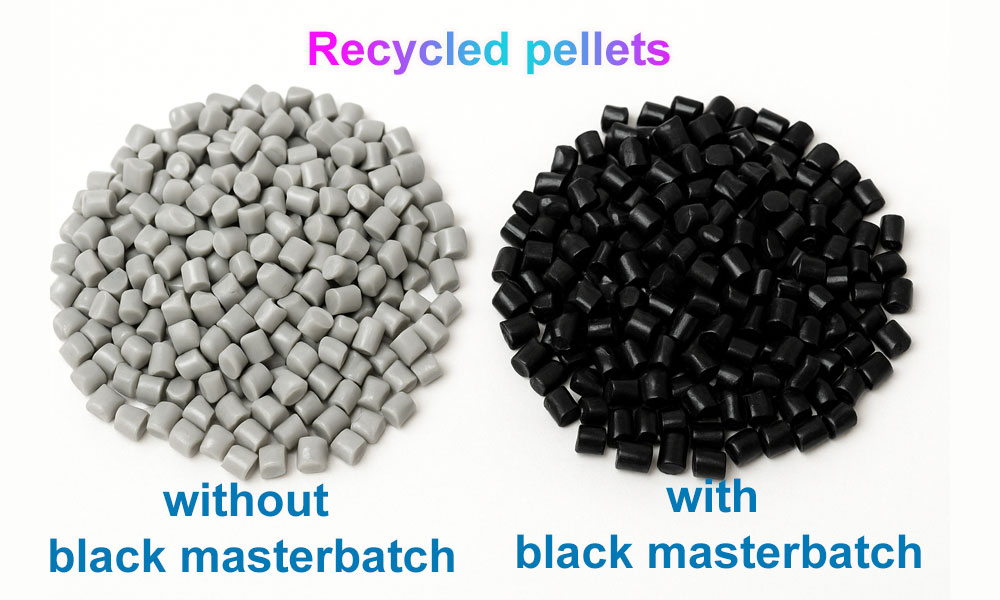

Color inconsistencies: Different batches look different.

Mechanical property fluctuations: Strength, impact resistance, and melt flow may vary.

Processing challenges: Impurities can interfere with extrusion or molding, increasing scrap.

Such challenges highlight the need for a high-quality black masterbatch.

How Black Masterbatch Helps

Black masterbatch addresses key challenges in recycled pellets:

Uniform Color: Masks batch-to-batch color differences for consistent products.

Enhanced Durability: UV stabilizers, antioxidants, and thermal stabilizers protect recycled pellets and extend lifespan.

Cost Efficiency: Reduces reliance on virgin resins while keeping quality high.

Introduction to Black Masterbatch

Black masterbatch is a concentrated mixture of pigments and additives. It is used to color plastic and improve performance. Manufacturers mix it with recycled or virgin pellets.

Applications: PE pipe, HDPE/PP film, agricultural product, packaging, and automotive part.

Benefits:

Hides uneven color in recycled pellets

Enhances UV and thermal resistance

Improves mechanical strength

Reduces waste and scrap

Black Masterbatch Technical Parameters

| Parameter | Typical Value | Notes |

|---|---|---|

| Base Resin | PE / PP | Application-dependent |

| Pigment Concentration | 5–15% | High-opacity grades available |

| Melt Flow Index | 5–15 g/10min | Ensures smooth extrusion |

| Density | 0.95–1.05 g/cm³ | Adjusted for PE or PP |

| UV Stabilizer | Optional | Enhances outdoor durability |

| Operating Temperature | 180–250°C | Suitable for extrusion/injection |

Real-World Example: PE Pipe Production

In India and Africa, PE pipe demand is rising due to infrastructure and irrigation projects. Many manufacturers mix recycled pellets with virgin material. Problems often appear in color and strength.

A Nigerian PE pipe manufacturer had uneven pipe color and weak compressive strength. They adopted high-opacity black masterbatch. Color became uniform, UV resistance increased by 30%, and they supplied municipal water projects successfully.

Another company in Vietnam used recycled pellets for agricultural tubing. Pipes showed surface defects and poor outdoor durability. Introducing black masterbatch solved these issues. Products now last longer under sunlight exposure, with consistent mechanical properties.

These examples show why partnering with a reliable black masterbatch supplier is crucial.

Global Market Trends

Asia-Pacific: India, Vietnam, and Indonesia expand pellet production. Urbanization and infrastructure drive demand.

Africa: Municipal water, gas, and irrigation projects boost recycled pellets and black masterbatch usage.

Europe & North America: Food-grade and potable water-grade pellets require certified black masterbatch.

Sustainability: Functional masterbatches boost performance , meet environmental standards.

Opportunities for Manufacturers

High-performance products with durable, consistent recycled pellets

Technical support from suppliers offering trial runs and formulation guidance

Growth in emerging markets like Southeast Asia and Africa

Compliance with ISO, fda, or RoHS standards for regulated markets

Functional additive integration for flame retardancy, anti-static, or UV protection

Challenges

Raw material variability affecting batch consistency

Virgin resin price fluctuations impacting blended pellet cost

Regulatory differences in different export regions

Competition from low-cost local black masterbatches

Conclusion

The recycled plastic pellet market is growing steadily. Quality stability remains a key challenge. High-quality black master batch ensures uniform color, better durability, and lower scrap rates.

Choosing the right black masterbatch supplier is critical for success. Combining recycled pellets with black master batch and functional additives produces sustainable, high-quality products while controlling costs.