Products Description

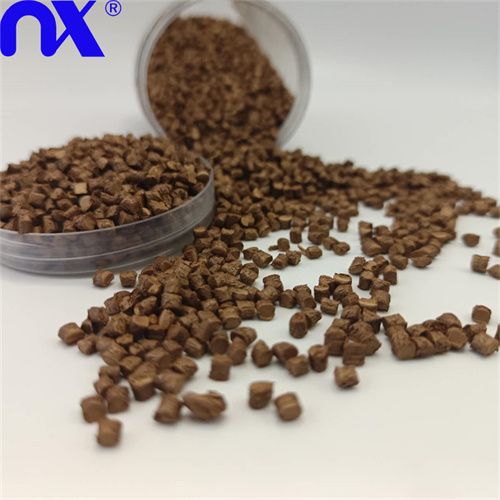

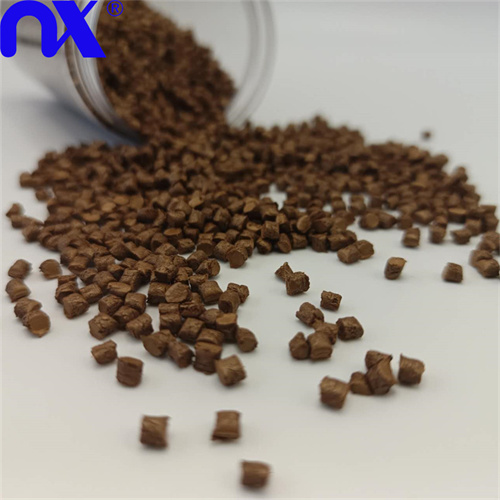

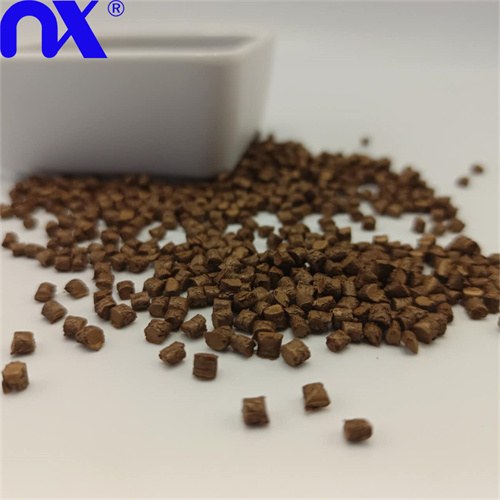

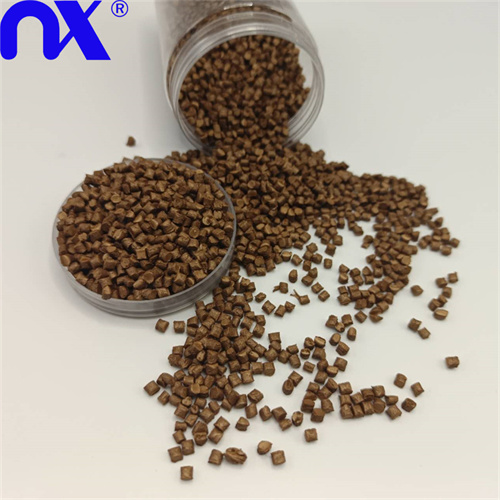

Our brown masterbatch is made with a specialized formula, using high-quality polyethylene (PE) and polypropylene (PP) as its base carriers. These two materials have long been well-regarded in the plastic processing industry for their top-notch performance. When used as carriers, they do more than just keep the masterbatch’s physical and chemical properties stable—they also make sure it mixes exceptionally well with most plastic products made from PE and PP bases, things like injection-molded components, extruded sheets, and blown films. This strong compatibility is what lets the brown masterbatch spread evenly during production. It stops issues such as color flecks or patchy shading from popping up, and that’s how we guarantee consistent quality in every batch of finished goods.

![Brown Masterbatch for Blown Film Brown Masterbatch for Blown Film]()

Physical Characteristics

carrier | PP/PE |

Toner content | 10%-50% |

melt index | 10-30g/10min |

compatibility | PE/PP/PVC/ABS |

Packing Specifications | 25kg/bag |

Free Sample Quantity | <=500g |

Who pays for shipping? | Buyers |

Add Scale | 1:25-1:50(According to product specific requirements) |

Package | Injection molding composite bag, PE valve bag, PE sticky bag, PE transparent valve bag |

Is the sample free | Free for up to 5 kg, extra charges |

materials | Recycled materials and virgin materials |

color | Red, orange, yellow, green, cyan, blue, purple, gray, white |

Application Area

Brown masterbatch is most commonly used in plastics—it works with nearly every plastic molding process out there. It checks the boxes for different needs, from getting the right brown look to meeting performance standards like standing up to weather or heat.

In general-purpose plastic molding, it’s everywhere. For polyethylene (PE), that means shopping bags, trash bags, and plastic buckets. For polypropylene (PP), it goes into storage boxes, toys, and car interior parts such as door panels and pillars. Here, its big jobs are keeping colors even—no “color spots” from lumpy pigment—and cutting down on pigment dust, which makes the production area cleaner. It also fits right into common processes: injection molding, blow molding, extrusion—you name it.

Engineering plastics need a tougher brown masterbatch, though. Take polyamide (PA, or nylon), used for mechanical gears and cable ties; polycarbonate (PC), for electronic housings and lampshades; or ABS, for appliance casings like coffee machines or ovens. These plastics need higher processing temps—PA, for example, is usually processed at 240-280℃—so the masterbatch must handle high heat well. Some uses, like outdoor electronic parts, also call for weather resistance, to stop the product from fading when exposed to sunlight.

![applicantion area.jpg applicantion area.jpg]()

Company profile

Nuoxin New Materials (Shandong) Co., Ltd., which is situated in Shandong Province, China, the company is specialized in selling high-quality color, white, black and various functional masterbatches as well as filling masterbatch.

The factory has been engaged in the development and manufacture of plastic masterbatch since 2016.

Our popular sale products involve black masterbatch, color masterbatch, desiccant masterbatch, calcium carbonate filled masterbatch, sodium sulfate transparent nanometer filled masterbatch and so on, which are widely applied in film blowing, injection molding, pipes, cables and other industries.

![company profile.jpg company profile.jpg]()

Exhibition

Nuoxin New Materials (Shandong) Co., Ltd. is a top player in the masterbatch industry—they’re both an integrated manufacturer and a global supplier. What really sets them apart is their solid manufacturing base. They’ve got advanced tech backing that base up, plus super strict quality control, and together these things make sure they can put out masterbatch solutions that perform really well, no matter what customers need.

You’ll also see Nuoxin at major masterbatch shows all over the world—they’re pretty active there. At these exhibitions, they don’t just set up booths; they bring out their newest creations too. It’s a great way for industry partners and people who might want to work with them to get a close look at what’s new. And beyond showing off products, these events help Nuoxin get their name out more in the global market—so more countries and regions start to know what they’re capable of.

Nuoxin’s always been big on doing things right—they push for excellence in everything, from R&D work to making products and even talking to customers. That focus on quality and trying new things has paid off. They’ve built long-term, steady business relationships with customers from all kinds of industries. Those partnerships aren’t just a sign that clients trust Nuoxin; they also give the company a strong foothold to keep growing in the international masterbatch space.

![exhibition.jpg exhibition.jpg]()

Loading and shipping

We offer several packaging choices to fit different needs—you can go for 25-kilogram bags, or opt for the 1000-kilogram FIBC (flexible intermediate bulk containers) instead.

Our packaging uses fully enclosed design, which works like a tight barrier against both dust and moisture. That way, the masterbatch stays dry and clean the whole time it’s stored, and there’s no chance of moisture messing with how the product performs later on.

Every package is fully wrapped and fixed securely too. For the kraft paper bags, we wrap them all the way from the top to the bottom of the pallet—this builds a tough protective layer around everything. It does a great job of stopping masterbatch from leaking out, even if the packaging gets a little damaged while being transported.

You don’t have to worry about pressure or bumps either. The kraft paper bags are made with strong material, and when combined with the full wrapping, they end up with really solid structural stability. They can handle the weight of multiple stacked layers no problem, and even if there’s a small impact during handling or when loading/unloading, the masterbatch inside stays well-protected.

Moisture resistance is another big plus. Kraft paper has natural moisture-resistant properties, and the tight seal from the wrapping adds a second layer of protection. This makes the packaging perfect for storing in rainy areas or warehouses that tend to be humid.

![packing and delievery packing and delievery]()

![package package]()