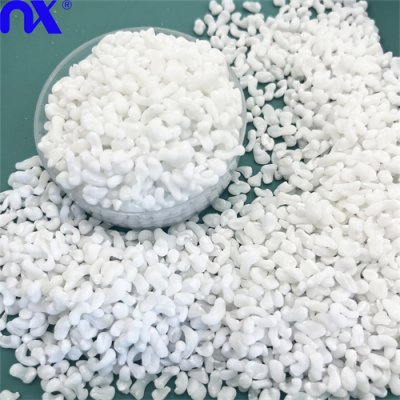

Plastic Filler

Looking to optimize costs and enhance your plastic products

We offer high-quality filler masterbatches perfect for various applications, including:

1.Injection Moulding: Reduce material costs while maintaining product strength and dimensional stability.

2.Blown Film: Lightweight your films for improved efficiency and cost savings without compromising performance.

3.Non-Woven Fabrics: Enhance bulk and improve handling characteristics of your non-woven products.

Here's what NUOXIN Filler Masterbatches can do for you:

1.Cost Savings: Reduce material costs significantly compared to virgin plastic.

2.Improved Processability: Certain fillers can enhance flow properties, making plastics easier to mold and reducing production cycle times.

3.Enhanced Properties: Depending on the filler type, you can improve stiffness, heat resistance, and other functionalities.

4.Lightweighting: Reduce the weight of your plastic products for easier handling, lower transportation costs, and a smaller environmental footprint.

Sodium sulfate filler masterbatch: has excellent transparency and glossiness, and can significantly improve the appearance quality of plastic products. It has good compatibility with plastic resins, excellent dispersibility, and has little effect on the mechanical properties of plastics (such as tensile strength and impact strength), and can even improve the flexibility and impact resistance of products to a certain extent

Ready to explore the potential of filler masterbatches? Contact NUOXIN today!

Calcium carbonate filler masterbatch: used to increase rigidity and hardness, reduce costs, and is widely used in PE, PP and other resins.

Talc filler masterbatch: improves rigidity and dimensional stability, suitable for polyethylene film, ABS resin, polypropylene, etc.

Cost and Price Advantage

- Direct Production and Sales: By engaging directly in manufacturing and sales, the factory bypasses intermediary stages, effectively controlling costs and offering more competitive pricing.

- Economies of Scale: Through large-scale production, the factory achieves economies of scale, further reducing costs.

Production and Quality Control

- Production Autonomy: The factory owns its own production lines and equipment, allowing it to independently schedule production plans and ensure timely delivery.

- Quality Control: Direct involvement in the production process enables the factory to strictly monitor product quality, ensuring that products meet the high standards of its customers.

Communication and Efficiency

- One-Stop Service: Typically equipped with sales, production, and after-sales departments, the factory offers a one-stop service where clients can complete business negotiations, product acceptance, and after-sales support within the same company, enhancing communication efficiency.

- Quick Response: The factory is capable of responding rapidly to customer needs, reducing communication layers and improving overall efficiency.

After-Sales and Support

- Robust After-Sales Capability: The factory can directly connect with its production departments to provide comprehensive after-sales support, ranging from repairs and improvements to R&D.

Large-Order Capacity

- Production Scale: The factory boasts strong production capabilities, enabling it to handle large-scale orders and meet the needs of wholesale or distributor clients.

- Customer Trust: With stable products and services, the factory is more likely to earn the trust of major clients.

International Standards

The factory can tailor its products and services to meet international market requirements, ensuring compliance with global standards.

Long-Term Partnership and Stability

- Stable Supply: The factory can provide a consistent supply, minimizing risks associated with supplier changes.

- Long-Term Cooperation: Clients who establish long-term partnerships with the factory can enjoy more favorable pricing and services.

Feel free to let me know if you need plastic Filler!

Reducing costs: By adding a certain proportion of filling masterbatch, the amount of resin used can be reduced, thereby reducing the production cost of plastic products.

Improving processing performance: Filling masterbatch can improve the rigidity, dimensional stability, heat resistance and creep resistance of plastics, while improving thermal stability and melt flow index during processing.

Giving special functions: Depending on the filling material, filling masterbatch can also give plastic products special functions, such as wear resistance, conductivity, flame retardancy, etc.

Good dispersibility: Filling masterbatch pre-disperses the filler in the resin carrier, avoiding the agglomeration problem of the filler during processing, and improving the dispersion of the filler and the quality stability of the product.

Environmental protection: Modern filling masterbatches mostly use environmentally friendly and non-toxic raw materials, which meet national and international environmental protection standards.