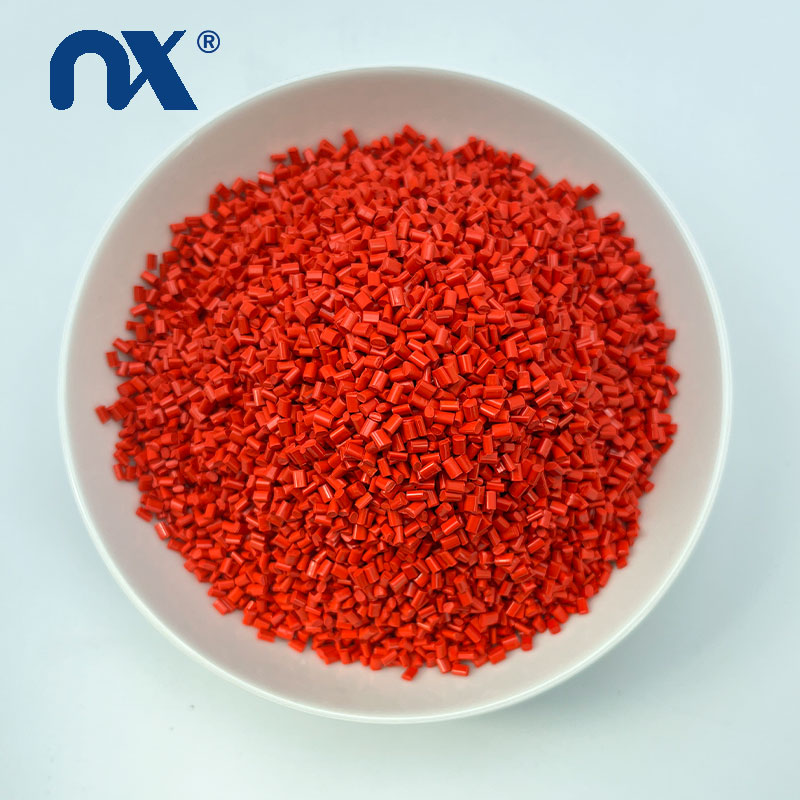

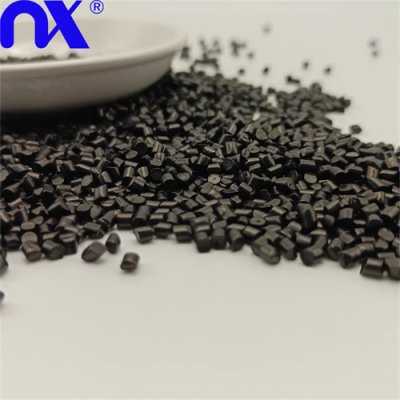

PET Master Batch

Experience: Over 10 years focusing on master batches and color solutions.

Consistency: Each lot tested for MFI, color dispersion, and moisture.

Custom Development: Pantone and RAL shades with fast turnaround.

Capacity: Scalable production for both bulk and custom orders.

Global Reach: Exported to 50+ countries with satisfied customers.

Technical Support: R&D team helps resolve processing challenges.

This mix of reliability and technical depth is what keeps clients returning. We don’t just sell pellets; we help you make your product look and perform better.

High-performance PET master batches for consistent color, stable processing, and practical production results.

When people talk about consistent color in plastic manufacturing, it is often one of the first materials that comes up. Our PET Masterbatch has been designed for producers who value reliability, color stability, and smooth processing performance. It’s not just about giving plastics a bright shade—it’s about helping you maintain quality from the first pellet to the final molded product.

Unlike some generic master batches on the market, this one is carefully formulated with selected pigments and additives that bond well with PET resin. Every batch is made with a clear goal: to deliver uniform dispersion, high tinting strength, and lasting brightness even after multiple heat cycles. This is what we mean when we talk about a performance master batch—it’s not just color, it’s performance built into every pellet.

Why PET Masterbatch Matters

If you’ve ever tried to produce PET preforms, bottles, or films, you know how sensitive the resin can be to temperature, drying, and additive balance. A poorly dispersed colorant can ruin transparency or cause streaks that waste both time and material. That’s exactly why a stable PET masterbatch is so important.

Our formula minimizes moisture absorption, improves melt flow consistency, and ensures that color distribution stays even throughout the extrusion or molding process. We’ve tested it across different lines—sheet extrusion, injection stretch blow molding, fiber spinning—and it keeps showing reliable results. Customers often mention that our product feels “easy to use.” That’s probably because it was developed through years of trial, error, and direct feedback from real production floors.

Product Highlights

Bright, Stable Colors: Designed for PET applications that demand clarity and gloss.

Excellent Dispersion: Prevents streaking and color separation during processing.

High Compatibility: Works with virgin and recycled PET alike.

Controlled Moisture Level: Less than 0.2%, ensuring steady extrusion.

Thermal Stability: Endures 260°C processing without discoloration.

RoHS and heavy-metal-free: Safe for packaging and consumer products.

Each of these points may look simple, but behind them is a detailed formulation and a production method tuned for PET’s unique properties. As an experienced master batch supplier, we make sure every step—from pigment selection to final packaging—is documented and traceable.

Technical Specifications

| Property | Typical Range / Value | Notes |

|---|---|---|

| Carrier Resin | PET | Designed for full compatibility with PET polymers |

| Pigment Content | 20% – 80% | Depends on target shade and opacity |

| Moisture Content | ≤ 0.2% | Tested after drying |

| Melting Range | 240°C – 260°C | Stable at common PET processing temperatures |

| Form | Uniform granules / pellets | No visible agglomeration |

| Dosage | 1% – 4% | Adjustable based on color intensity |

| Compliance | RoHS, REACH | Certificates available |

Applications by Material Type

Because not all plastics behave the same, we also provide guidance based on the base resin used. Below are common application areas and practical notes from the field.

1. PET Masterbatch Applications

Perfect for PET bottles, cosmetic packaging, beverage preforms, and transparent films. Many bottle producers use our color masterbatch to achieve deep blues, greens, and ambers without affecting clarity. It’s also common in textile-grade PET fiber spinning, where uniformity across long runs is critical.

2. Polyethylene (PE) Based Masterbatches

While PET is our focus here, we also offer related master batches for polyethylene film, sheets, and injection products. These focus on flexibility and even color stretch during film blowing.

3. Polypropylene (PP) Masterbatches

Used in injection molding, woven bags, and household goods. PP can be sensitive to pigment migration, so our PP-compatible masterbatch avoids fading or blooming over time.

4. PVC Master Batch Applications

For cable sheathing, pipes, and decorative films. We adjust plasticizer and stabilizer balance to ensure brightness and weather resistance in PVC applications.

In each category, the principle remains: the right performance master batch saves you downtime and reduces scrap rates.

Packaging and Storage

Packaging is available in standard 25 kg woven bags, with moisture-proof inner liners for sensitive grades. For export orders, we also provide palletized wrapping and custom labeling upon request. Store the masterbatch in a dry, ventilated place, away from direct sunlight and heat. Use within twelve months for best results. In humid regions, re-drying before use is recommended—especially for PET.

Factory Direct Supply Advantages

Buying directly from the manufacturer makes a real difference. We’ve produced and exported master batches for over a decade, which means pricing is competitive and logistics are dependable. There’s no chain of agents inflating costs, and communication stays clear between your team and our engineers.

We control every step: pigment testing, twin-screw compounding, pelletizing, and final inspection. This direct model lets us respond quickly if you request a new color or a slight formula tweak. Long-term partners often cite our flexibility and speed on small trial lots as a key advantage.

Customer Cases and Real Feedback

A PET bottle manufacturer switched to our color masterbatch after struggling with streaking in preforms. They reported a smoother color flow and a 10% improvement in transparency compared with their previous supplier.

The company needed a stable blue masterbatch for high-speed fiber spinning. Our technical team adjusted the carrier ratio, and the client confirmed improved consistency after 30 hours of continuous production.

“Color strength is impressive and very consistent. We’ve worked with several suppliers before, but these guys listen, test, and respond faster than others. It’s like having a partner rather than a vendor.”

Distributor Policy

We’re expanding our distributor network for PET and color masterbatches. Partners receive exclusive territory rights, competitive wholesale pricing, and access to marketing resources such as brochures and sample kits. We provide online and on-site technical training for our partners. If you are interested in representing our performance master batch line in your region, please contact our sales department for terms and cooperation plans.

Contact Us

If you are looking for dependable master batches that enhance your PET production line, contact our team today. Whether you need a special effect color, a performance master batch for UV protection, or a cost-effective color solution, we are ready to help.

Email: zina@nuoxinplastic.com

WhatsApp: +86 13506417921