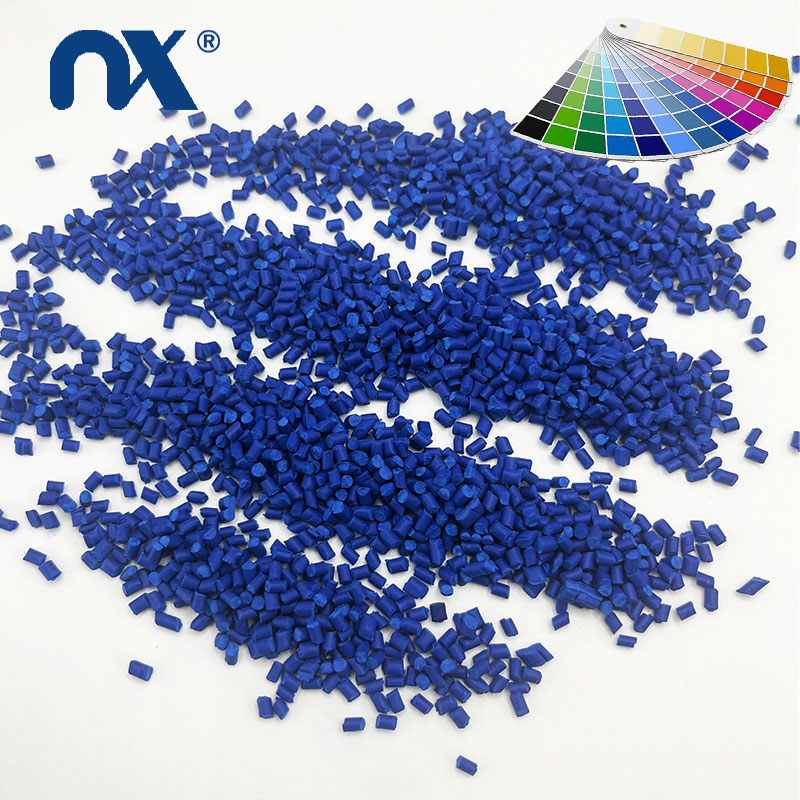

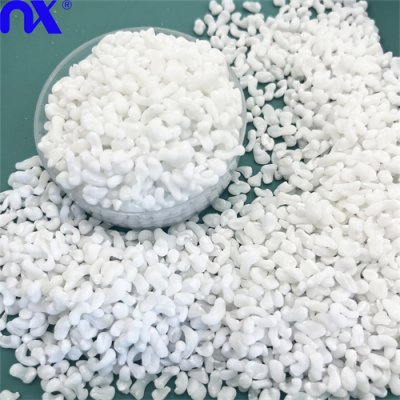

PE Masterbatch

· High-Quality Pigments: Only premium-grade pigments are used, ensuring vibrant, consistent color in every batch.

· Customizable Formulations: Tailored to meet specific customer needs, including unique colors and additive combinations.

· Cost-Effective: Reduces the need for expensive raw materials without compromising quality.

· Reliable Supply: Consistent production capacity and stringent quality control ensure reliable delivery.

Product Overview

Our PE Masterbatch is a high-quality, colorant or additive designed for enhancing the properties and aesthetics of polyethylene (PE) plastic products. The masterbatch is available in a variety of colors and formulations. It is made using premium pigments and resins to ensure excellent dispersion, superior color stability, and compatibility with different grades of PE. This product is ideal for use in a wide range of applications, from films and packaging to injection molding and extrusion.

Product Parameters

Carrier Resin | Polyethylene (PE) |

Pigment Content | 10%-50% |

Melt Flow Index (MFI) | 2-15 g/10 min (customizable) |

Density | 1.2-1.5 g/cm³ |

Dosage | 1%-8% depending on the application and product requirements |

Color Options | Black/White/Colors/ Full range available (custom colors available upon request)

|

Form | Granular |

Product Details

PE Masterbatch is designed for ease of use in various PE processing techniques, including extrusion, blow molding, and injection molding. Its superior dispersion ensures that pigments and additives are evenly distributed throughout the plastic matrix, providing consistent color and performance. PE Masterbatch is available in both standard and custom formulations to meet specific customer requirements, offering flexibility in production and design.

Product Recommendations

· PP Masterbatch

· ABS Masterbatch

· PET Masterbatch

· PLA Masterbatch

Product Function Description

· Color Enhancement: PE Masterbatch Delivers vibrant, long-lasting colors for PE plastic products.

· Additive Benefits: Provides additional functionalities such as UV resistance, anti-static properties, and flame retardancy.

· Improved Processing: Enhances flow and processing efficiency, reducing production cycle times.

· Cost Efficiency: Reduces the need for raw pigments and additives while maintaining high-quality results.

Application

· Plastic Films: Used in the production of high-quality films for packaging, agriculture, and industrial uses.

· Injection Molding: Suitable for consumer products, toys, and household items made from polyethylene.

· Blow Molding: Ideal for producing PE bottles and containers.

· Extruded Sheets and Pipes: Provides smooth surface finish and improved strength in PE sheets and pipes.

Production Workshop

Our production facilities are equipped with state-of-the-art extrusion and mixing machines that guarantee high-quality masterbatch production. Strict quality control processes are followed at every stage, from raw material selection to final product packaging.

Exhibition

We regularly participate in major plastic and chemical industry exhibitions such as Chinaplas, ALLPACK, and Canton Fair. These events provide an opportunity to showcase our latest masterbatch innovations and connect with customers and partners worldwide.

Contact Us

For inquiries or to place an order for our PE Masterbatch, please get in touch:

· Email: zina@nuoxinplastic.com

· Phone:+8618660167636

· Website: www.nuoxinmasterbatch.com/

· Address: North of East Development Zone, Xuyuanzi Township, Qingyun County, Dezhou City, Shandong Province