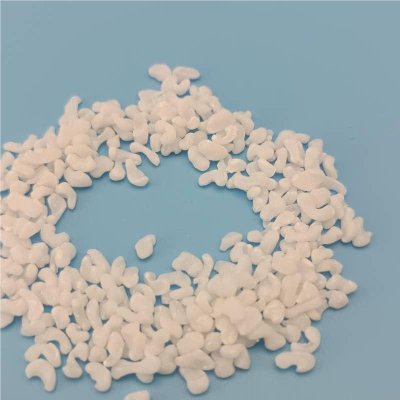

Transparency Sodium Sulfate Filled Masterbatch

Product advantages:

Compared with ordinary filling masterbatch, transparent fillingmasterbatch is characterized by adding transparent filling masterbatchto PP,PE, which has little influence on PP,PE transparency, andtransparent filling masterbatch can also be widely used in film, sheetmaterial, pipe, container and other fields.

Color:colorless

Add Scale: Woven bags, container bags, hollow boards, supermarket shopping bags.

injection molding products

Product Overview

Sodium sulfate transparent filler masterbatch is a specialized formulation created through the extrusion and granulation of polyethylene resin combined with a transparent filler. This masterbatch can be incorporated into various products, such as films, sheets, and injection-molded items, in specific ratios. It effectively maintains product quality while also helping to lower production costs.

Transparent Filler Masterbatch

LDPE/HDPE/PP/PE/ABS | |

| MFI(190℃,5KG) | 4.5-21.3g/10min |

| Melting | 114℃ |

| Density | 1.44g/cm3 |

| Add Ratio | 4%-61% |

| Single screw addition amount | 5%--16% |

| ABA machine addition amount | Add 42%--82% to Layer B |

| Certificate | RoHS、U.S.FDA21CFR177.1520 |

Application

· Blown Film: Used in plastic films to maintain transparency and reduce costs.

· Packaging: Ideal for producing cost-efficient and strong packaging materials.

· Injection Molding: Widely used in the production of plastic parts, ensuring strength and reducing production time.

· Extruded Sheets and Pipes: Provides a smooth surface finish and enhanced durability in extruded products.

· Household Products: Enhances the cost-efficiency an d quality of items such as containers, tubs, and more.

Our Advantages

Qingyun Nuoxin Plastic New Materials Co., Ltd., established in January 2016, integrates product development, production, sales, and technical services into one of the leading functional masterbatch manufacturers. Our main products include nano barium sulfate degradable masterbatch, defoaming (water absorption) masterbatch, calcium carbonate functional masterbatch, black masterbatch, color masterbatch, and more.

Spanning over 60 acres with an annual production capacity of 78,000 tons, our masterbatches find extensive applications in blow molding, injection molding, pipelines, drip irrigation belts, plastic weaving, blown film, cable sheaths, geomembranes, geogrids, agricultural mulch films, lunch boxes, PE water supply pipes, and various other industries. All Nuoxin Plastic products undergo rigorous quality testing to ensure reliability and performance.

Product Packaging

Selling Units:

Single item

Single package size:

75X45X20 cm

Single gross weight:

25.0 kg

FAQ

· Q1: What is the recommended dosage for Na₂SO₄ Filler Masterbatch?

A1: We recommend a dosage of 5%-40%, depending on the required transparency and mechanical properties.

· Q2: Can the product be customized?

A2: Yes, we offer custom formulations to meet your specific requirements.

· Q3: What is the delivery time?

A3: Standard orders are delivered within 7 days; customized orders may take slightly longer.

· Q4: Is the product compatible with all polymers?

A4: Our Na₂SO₄ Filler Masterbatch is primarily designed for PE and PP but can be tailored for other polymers as well.