Sodium Sulfate Filled Masterbatch

Superior Transparency: Maintains high optical clarity even with increased filler loading.

Excellent Dispersion: Uniform particle distribution ensures smooth extrusion and consistent film thickness.

Cost Reduction: Decreases resin usage while preserving film strength and flexibility.

High Compatibility: Suitable for LDPE, HDPE, and PP resin systems in both single-layer and multi-layer films.

Stable Processing: Offers good melt flow and thermal resistance under continuous operation.

Certified Safe: Complies with RoHS and MSDS FDA standards.

Na₂SO₄ Masterbatch for PP and PE Film

Product Introduction

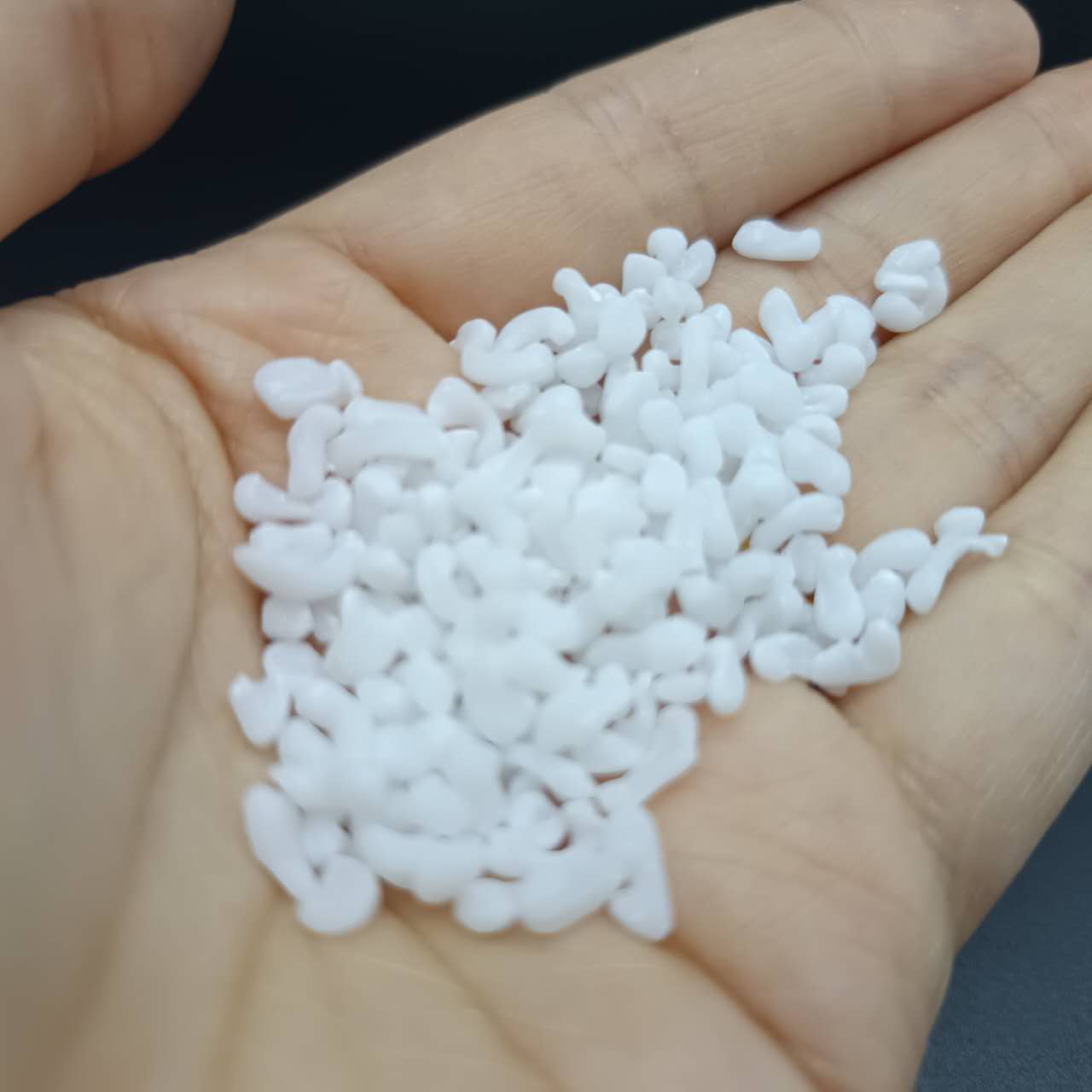

Sodium Sulfate Filler Masterbatch is a high-quality additive developed to enhance film transparency and cut down resin usage. It helps manufacturers lower production costs while keeping product performance stable. The masterbatch is made by mixing polyethylene resin with ultra-fine sodium sulfate powder through advanced extrusion and granulation. The result is a product with good dispersion, steady heat resistance, and clear optical effect.

The Filler masterbatch is specially designed for PP and PE film. It provides a cost-effective and eco-friendly choice for extrusion, sheet forming, and injection molding processes.

Why Sodium Sulfate Masterbatch Is Perfect for Blown Film

Na2SO4 masterbatch offers superior compatibility with PE and PP resins, ensuring high transparency and mechanical balance. Itis fine particle size (1500-6000 mesh) allows even distribution, minimizing haze and maintaining film clarity.

When used in blown film applications, it provides:

💡 Minimal impact on transparency—adding the appropriate ratio does not affect product clarity.

⚙️ Smooth extrusion and stable melt flow make it suitable for multi-layer co-extrusion lines.

🧊 Enhances cooling and bubble stability, reducing film breakage during production.

💰 Reduces raw material costs and can improve strength and performance to a certain extent.

Common applications include shopping bags, food packaging films, garbage bags, agricultural films, and construction membranes.

Technical Parameters

| Main Ingredient | Sodium Sulfate |

|---|---|

| Particle Fineness | 1500-6000 Mesh |

| Sodium Sulfate Content | ≥80% |

| Carrier Resin | LDPE / HDPE / PP / PE |

| Melt Flow Index (190°C / 5kg) | 4.6 – 21.4 g/10min |

| Melting Point | 115°C |

| Density | 1.44 g/cm³ |

| Recommended Dosage | 10% – 70% (Depending on extrusion process) |

| Color | Transparent White |

| Form | Irregular Granules |

| Certificates | ISO 9001, RoHS, FDA |

Applications

This Filler masterbatch is widely used in various plastic production fields, such as:

Film Extrusion: Agricultural films, packaging films, composite films, and milk films.

Sheet & Plate: Thermoforming sheets, construction panels, and transparent sheets.

Injection Molding: Containers, lunch boxes, caps, and household items.

Pipe Extrusion: Water supply pipes, geomembranes, drainage systems.

Plastic Bags: garbage bags, and shopping bags.

About the Manufacturer

Nuoxin is a professional manufacturer specializing in plastic masterbatch since 2016. With an area of over 60 acres and an annual capacity of 100,000 tons, the company integrates R&D, production, and technical service to provide reliable solutions for global clients.

Main Products:

Sodium Sulfate Filler Masterbatch,

Calcium Carbonate Filler Masterbatch,

Nano Barium Sulfate Masterbatch, Desiccant Masterbatch,

Black 、White and Color Masterbatch.

All products undergo strict quality control to ensure stability and excellent dispersion performance in extrusion, injection molding, and film blowing.

Packaging & Storage

Packing: 25 kg/bag (PE valve bag, paper-plastic composite, or transparent PE bag).

Storage: Keep sealed and stored in a dry, ventilated area.

Logistics: Professional, eco-friendly packaging ensures safe transportation for export orders.

Why Choose Us

Over 10 years of experience in filler and functional masterbatch production.

Strict quality control and stable global supply.

Customized technical support for different film and molding applications.

Fast sample delivery and responsive customer service.

Get complimentary technical formulation assistance when you order.

FAQ

Q1: Are you a factory or trading company?

We are a manufacturer of plastic masterbatch with more than 10 years of industry experience.

Q2: What is the typical dosage for film applications?

Recommended addition is 20%–50% for single-layer films and up to 80% for ABA multilayer films.

Q3: Can I request a sample?

Yes, we provide free samples for testing and evaluation.

Q4: What payment options are available?

We support T/T, L/C, and other international payment methods.

Get Your Free Sample

We understand that testing is the key to trust. Contact us today to receive a free sample of our Na₂SO₄ masterbatch and evaluate its transparency, processability, and performance in your own production line.

📩 Contact us now — our technical team will help you select the right grade and provide free formulation advice for your specific application.

Distributor Partnership Program

We’re always looking for new regional partners to grow with us.

If you become a Nuoxin distributor, you’ll enjoy:

💰 Special local pricing and priority delivery for your market

📢 Full marketing support and technical advice to help you promote

🎁 Free samples and formulation guidance for your customers

🤝 Co-branding options and shared resources to expand faster

Let’s work together to bring Na2SO4 Filler Masterbatch to more customers around the world.

💼 Contact us now and become our overseas partner. We will assist you in sales and make us a win-win partnership!