Enhancing Plastic Manufacturing Efficiency with PE Masterbatch

A Case Study

As global demand for cost-effective and high-quality plastic products continues to rise, manufacturers are constantly seeking innovative solutions to improve efficiency and product performance. One such solution gaining traction across various industries is PE Masterbatch, a powerful additive used in polyethylene (PE) production. This article explores how PE masterbatch is transforming the plastic manufacturing landscape, delivering benefits such as enhanced product quality, reduced production costs, and improved environmental sustainability.

Industry Challenge: Balancing Quality and Cost Efficiency

In today’s highly competitive market, plastic manufacturers face the challenge of delivering premium-quality products while keeping production costs under control. The need for vibrant colors, additional functionalities like UV resistance, and maintaining mechanical properties, all while reducing raw material usage, is a constant balancing act for producers of plastic films, packaging, and injection-molded products.

One major player in the plastic packaging industry, a leading film manufacturer, recently encountered these exact challenges. Despite a growing demand for colorful, durable, and UV-resistant plastic films, the company struggled to manage rising costs associated with using pure polyethylene and raw pigments.

Solution: Integrating PE Masterbatch for Superior Results

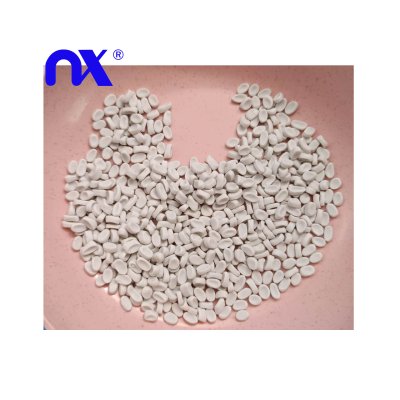

To address these challenges, the manufacturer turned to PE Masterbatch, a product designed to optimize polyethylene production by incorporating pigments and performance-enhancing additives into a polymer carrier. PE masterbatch allows manufacturers to achieve consistent, vibrant colors and additional properties, such as UV protection, while using less raw material.

After implementing PE masterbatch in their production line, the packaging company noticed immediate benefits:

1. Cost Savings: By reducing the reliance on pure polyethylene and raw pigments, the manufacturer saved approximately 15% in raw material costs.

2. Improved Processing: The enhanced flow properties of the masterbatch led to more efficient production cycles, cutting production time by 10%.

3. Superior Product Quality: The masterbatch allowed the company to create films with uniform color and enhanced UV resistance, critical for outdoor packaging applications.

Results and Industry Impact

The introduction of PE masterbatch not only improved the company’s bottom line but also positioned them as a more competitive player in the market. Their customers, including those in the agriculture and food packaging sectors, were impressed by the durability and vibrant appearance of the products. The films maintained their transparency and strength while offering the added benefit of UV protection, essential for extending product shelf life and enhancing consumer appeal.

Furthermore, by reducing the overall amount of virgin polyethylene required, the company contributed to a more sustainable production process, aligning with the growing global focus on environmental responsibility in manufacturing.

Future Outlook: Widespread Adoption of Masterbatch Solutions

The success of PE masterbatch in this case is indicative of a broader trend in the plastic manufacturing industry. As more companies look to optimize their processes while addressing environmental concerns, the demand for high-performance, cost-effective solutions like PE masterbatch is expected to grow.

Industry experts predict that the global masterbatch market will continue to expand as manufacturers in sectors such as automotive, packaging, construction, and consumer goods adopt these additives to enhance product performance and reduce costs. In the long term, this will lead to more sustainable and efficient production methods, benefiting both manufacturers and end consumers.

Conclusion

The implementation of PE Masterbatch in plastic manufacturing is proving to be a game-changer, helping companies strike the right balance between cost efficiency, product quality, and environmental sustainability. As industries worldwide continue to seek out innovative materials and processes, PE masterbatch will remain at the forefront of solutions designed to meet these evolving needs.

For manufacturers looking to stay competitive in the ever-changing plastic industry, adopting PE masterbatch could be the key to unlocking new levels of efficiency and product performance.