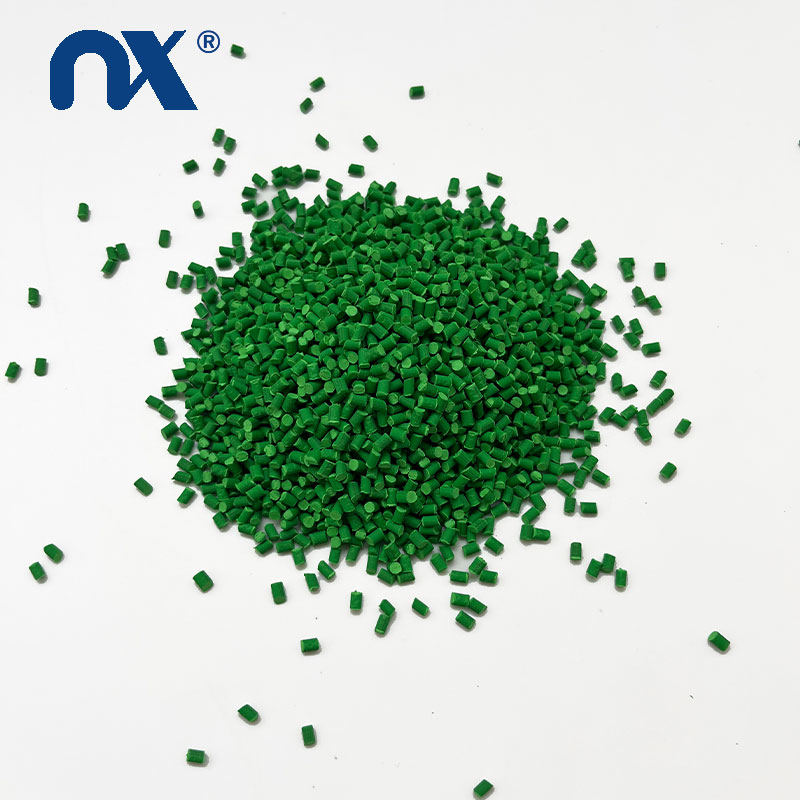

Light Green Color Masterbatch

Bright and Stable Color: Delivers a fresh light green shade with long-lasting stability and resistance to fading.

Excellent Dispersion: Pigments are evenly distributed, preventing streaks, spots, and uneven coloring.

High Coloring Strength: Achieves vivid color with low dosage, helping reduce production costs.

Wide Resin Compatibility: Suitable for PE, PP, ABS, and many other plastic materials.

Customizable Solutions: Supports color matching, sample testing, and custom formulations based on customer needs.

Introduction

The Light Green Color Masterbatch is a professional plastic colorant. Color MB offers a fresh and natural light green shade. The color is bright, clear, and stable. This is made with high-quality carriers and selected pigments. It shows strong coloring power. It disperses well and keeps long-term stability in plastic products.

This color masterbatch is not only a coloring material. It is also a solution for safe and cost-effective production. The product works with many resins. Common options include PE, PP, and ABS. Each batch is produced with advanced equipment. Each step follows strict quality control. The result is uniform color and reliable performance.

The light green color masterbatch gives plastic items a clean and modern look. It is used in packaging films, daily-use articles, and household goods. It is also suitable for some industrial products. Many manufacturers choose this green color masterbatch to improve product appearance. The benefits include stable color, reduced production cost, and higher market value.

Key Features

Bright light green: Clear, fresh, and natural tone.

Even dispersion: No streaks. No spots. Uniform finish.

High tint strength: Low addition rate. Strong effect.

Durable color: Resists sunlight and heat.

Resin versatility: Works with PE, PP, ABS, and others.

Certified safety: Meets ISO, ROHS, FDA, MSDS, TDS.

What You Can Customize

Shade and brightness of light green.

Carrier resin type to match your base resin.

Melt index and processing flow.

Additive package (UV, slip, anti-static on request).

Pellet size and packaging format.

We support custom color matching. We also provide sample testing and plate making before mass production.

Custom Color Development

Tailored Shade

Not all light green tones look the same. Brands choose different moods. Some need a softer pastel. Some need a vivid and crisp tone. We adjust pigment balance and carrier design. We achieve the exact shade you want. The result matches your target look under different lights.

Sample Testing & Plate Making

Send a reference sample or a color number. We analyze the shade in our lab. We produce test plates for your review. You can confirm accuracy before mass orders. This step cuts risk. It shortens the time to scale.

Fast Iteration

We keep the process simple. You share the target. We return plates and a small batch. You test on your line. We refine if needed. Most projects lock in within a short cycle. You save time and cost.

Application Areas

Packaging

Films, shopping bags, and containers use light green to signal freshness. The shade also helps brands stand out on shelf. The color stays stable in storage and transport.

Household & Consumer Goods

Bottle caps, storage boxes, organizers, and daily items benefit from a clean look. The finish feels smooth. The tone is consistent across batches.

Toys & Baby Products

Safety matters in this field. Our masterbatch meets major standards. The light green adds a friendly and cheerful touch.

Industrial & Automotive

Interior parts, trim pieces, and functional components need stable color. Heat and UV can be strong. The color holds up well in these conditions.

Agriculture

Pots, trays, and films use green tones outdoors. The appearance blends with the environment. The durability supports long service life.

Processing Benefits

Smooth blending with base resin.

Clean feeding and stable output.

Reduced dust vs. powder pigments.

Uniform color across wide runs.

Lower scrap from color defects.

Less downtime for adjustments.

Typical addition rate: 0.5% – 3% depending on shade and resin.

Factory Strength

Our site covers more than 40,000 m². We run 15 production lines. Annual capacity reaches 100,000 tons. We keep about 500 tons in stock. Many standard colors ship fast. We support urgent orders on request.

We use advanced extrusion and precise dosing. Batches stay stable. Pellets remain uniform. Every step is tracked. We test raw materials, inline samples, and finished goods. Certifications include ISO, ROHS, FDA, MSDS, and TDS.

We export worldwide. Customers in packaging, consumer goods, agriculture, and industry buy from us. They value stable shade, fast support, and consistent quality.

Quality Control

Incoming raw material checks.

Colorimetric analysis of shade.

Dispersion and melt flow tests.

Heat and light resistance checks.

Final inspection before packing.

We focus on repeatability. Your second order should match the first. Your tenth should match the second. This mindset drives our process design.

Market Trends

Green tones grow in demand. They signal health and sustainability. Light green sits well with eco-focused brands. It looks fresh on modern packaging. It also pairs well with natural imagery and clean layouts. As custom branding rises, unique greens matter more. Our color matching helps you lock in your signature look.

Why Choose This Masterbatch

Bright and stable light green.

Low dosage, strong tinting.

Clean dispersion, smooth surface.

Certified for global markets.

Custom color and quick plates.

Fast delivery and steady stock.

Usage Tips

Match carrier to base resin.

Dry base resin if needed.

Start at 1% and adjust.

Confirm shade with test plates.

Store bags sealed and dry.

Request Samples & Color Matching

Send your target shade, resin type, and process. Include a Pantone number or a physical sample if available. We will prepare plates and a trial batch. You can test on your line and confirm the result.

Support: Sample testing • Plate making • Rapid iteration • Mass production

Compliance & Safety

We design this product for safe use. We verify key regulations. We maintain traceable records for each lot. If your project needs extra tests, tell us. We can run additional checks or supply reports on request.

ISO quality management system.

ROHS compliance.

FDA-related documentation for suitable applications.

MSDS and TDS available.

Summary

The Light Green Color Masterbatch offers a fresh and modern shade. It delivers strong color with low dosage. It disperses well and keeps surfaces clean. It holds up in heat and light. It blends with common resins. It meets major standards. It is easy to specify and easy to scale.

We support custom colors, sample testing, and plate making. We keep stock for fast delivery. We operate with strict quality control. If your goal is a clear and stable light green, this masterbatch is a smart choice. It adds value. It lifts brand appeal. It helps your products stand out.