Filler Master Batch

· High-Quality Fillers: Made with premium-grade CaCO₃ and Na₂SO₄ for optimal performance.

· Customizable Formulations: Tailored to meet specific application and processing requirements.

· Excellent Dispersion: Ensures uniform filler distribution for consistent quality.

· Cost-Effective: Reduces material costs without compromising performance.

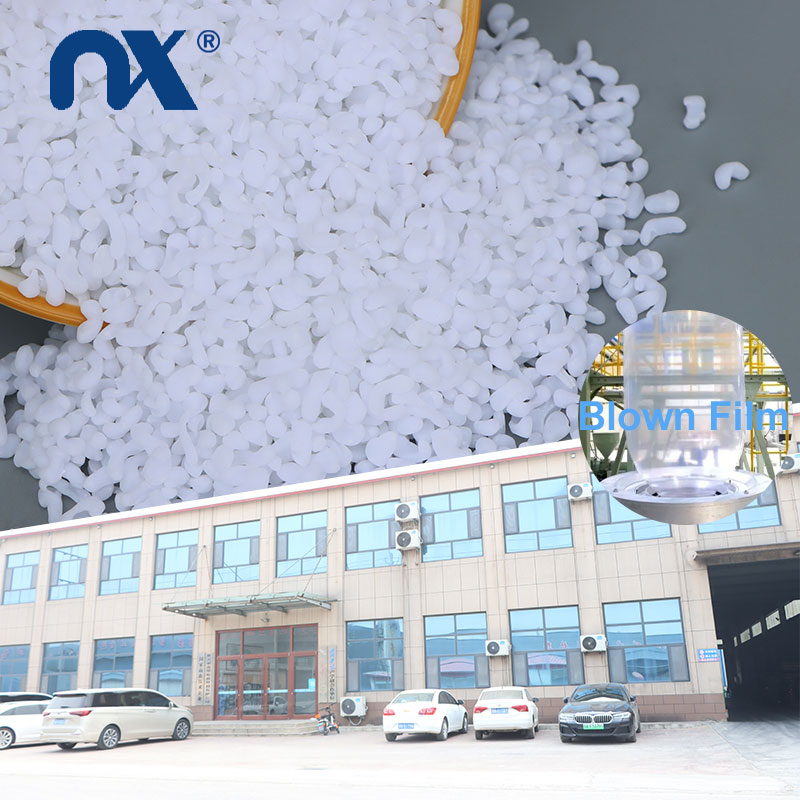

· Source factory: 10+ production experience, excellent quality and good price

Product Overview

Filler Master Batch is a cost-effective additive that not only reduces raw material costs but also improves the performance of plastic products. It is made by combining high-quality filler materials such as calcium carbonate (CaCO₃) or sodium sulfate (Na₂SO₄) with a compatible carrier resin. This masterbatch is widely used in the production of films, sheets, pipes and injection molded products. With excellent dispersion and compatibility, Filler Master Batch is a reliable solution for manufacturers seeking to optimize production without compromising quality.

Product Parameters

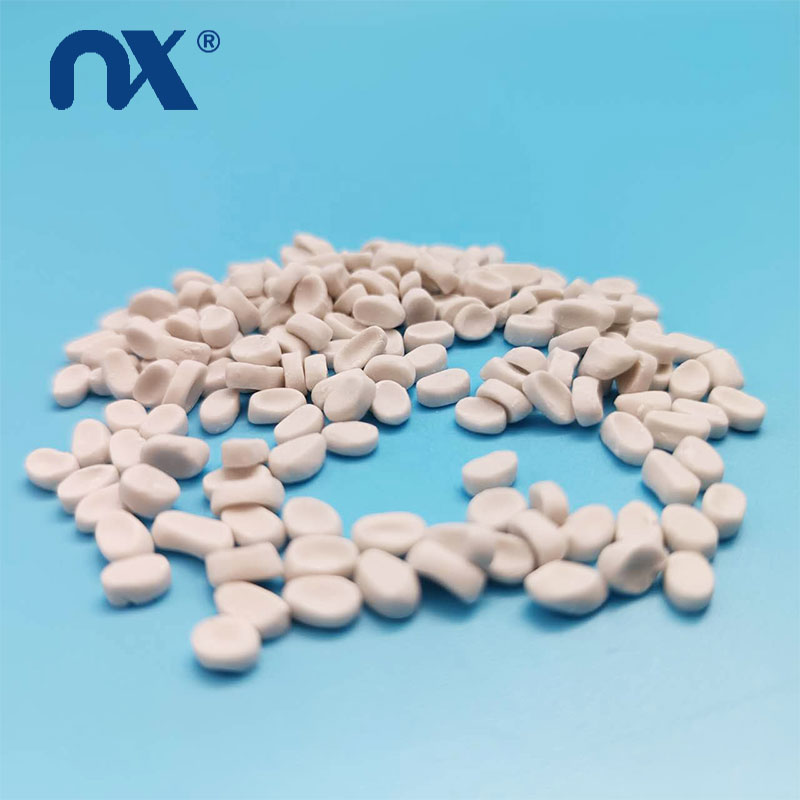

· Main Filler Material: Calcium carbonate (CaCO₃) or Sodium sulfate (Na₂SO₄)

· Filler Content: 70%-85%

· Carrier Resin: PE/HDPE/LDPE/ PP (or customizable)

· Melt Flow Index (MFI): 2-10 g/10 min

· Density: 1.5-1.9 g/cm³

· Moisture Content: ≤ 0.1%

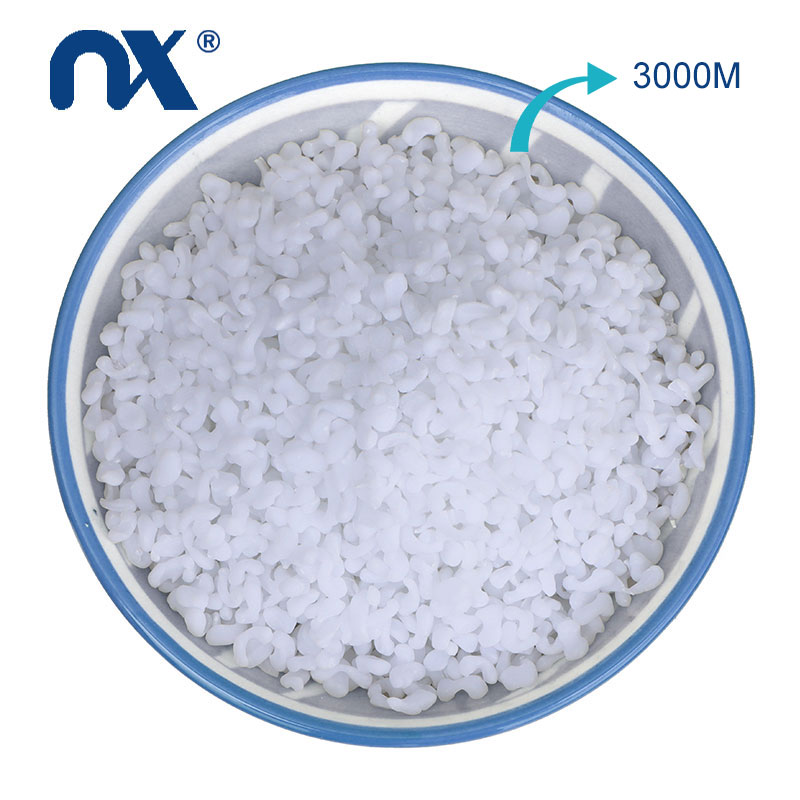

· Appearance: White or translucent granules

Product Function Description

· Reduce costs: Replace part of the expensive base resin with low-cost filler materials, greatly reducing production costs.

· Improve stretchability: The stretchability of plastic film products can be improved.

· Improve processing performance: Improve extrusion and molding efficiency, reduce cycle time and energy consumption.

· High transparency: Sodium sulfate filler master batch has little effect on the transparency of the product.

Application

· Plastic Films: Used in packaging, shopping bags, and agricultural films for added strength or opacity.

· Injection Molding: Ideal for household goods, automotive parts, and industrial components, offering better rigidity and cost savings.

· Pipes and Profiles: Enhances the durability and surface finish of PVC, PE, or PP pipes and profiles.

· Blow Molding: Suitable for manufacturing containers, bottles, and other hollow products, improving wall thickness and stiffness.

· Non-Woven Fabrics: Improves the bulk and opacity of spun-bonded and melt-blown fabrics.

Technical Support

Our technical team provides expert guidance on optimizing Filler Master Batch usage in various applications. From dosage recommendations to troubleshooting, we are here to support your production needs.

Company Qualifications

We are ISO9001 certified and adhere to international standards such as FDA and RoHS. Our commitment to quality and sustainability ensures that our products meet the needs of global markets.

Company Strength

With years of experience in the masterbatch industry, we are a trusted supplier for customers in over 30 countries. Our focus on innovation and customer satisfaction has established us as a market leader.

FAQ

· Q1: What is the recommended dosage for Filler Master Batch?

A1: The typical dosage ranges from 5% to 50%, depending on the application and desired properties.

· Q2: Is it compatible with all types of resins?

A2: Our Filler Master Batch is compatible with PE, PP, EVA, and other thermoplastics.

· Q3: Can I request a custom formulation?

A3: Yes, we offer tailored formulations to meet specific application needs.

· Q4:How to Get Samples?

A4: To request a sample of our Filler Master Batch, please contact us by email or phone. Samples are available for testing, and our team is ready to assist you in achieving the best results.