Recycled Plastic Pelletizing is Growing Fast — Color and Quality Take Center Stage

In recent years, recycled plastics have moved from being a side topic in the polymer industry to a major talking point in every production meeting. Factories in Asia, Africa, and Europe are expanding their recycling lines. New compounding equipment is being installed almost every month. What was once seen as a small-scale environmental project has become a real business with strong demand and clear economic value.

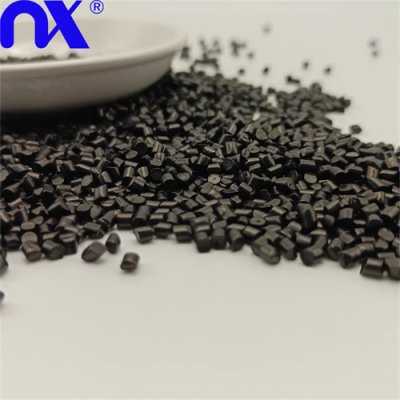

This growth, however, has brought new challenges. The biggest one is not the technology or supply chain — it’s the stability of product quality. Every recycler wants to produce consistent pellets, but the reality is that recycled materials behave differently from batch to batch. The color, gloss, and strength of the output can change even when the input waste looks the same.

Plastic pelletizing used to be predictable when virgin resins were the main feedstock. The base polymer had a uniform color and melt flow. But recycled plastics are a mix of many sources: bottles, films, and industrial scrap. Even after cleaning and filtering, each source still carries traces of its previous life. These small differences are enough to affect the final look and feel of the product.

What makes the issue even more visible is color. Color speaks first to the consumer. Whether it’s a bright detergent bottle or a calm blue water jug, color consistency tells people that a brand is reliable. If one batch looks duller or slightly off tone, customers notice immediately. That is why the appearance of recycled products has become a key indicator of quality.

In the push toward sustainability, companies are realizing that color control is not just cosmetic — it’s strategic. A brand can only promote “green” products successfully if they still look professional and appealing. Yet, achieving that balance is complex. Recycled polymers often come with yellow or gray undertones that distort any new color added during processing.

This is where red masterbatch and blue masterbatch become important. They are not only tools for coloring but also instruments for correction. A blue masterbatch can neutralize the yellow tint in recycled PET. A red masterbatch can bring life back to a dull, gray recycled PP. Both help recyclers regain control over the color outcome without adding large amounts of pigment or using virgin resin.

Over time, the role of masterbatch in recycling has expanded far beyond appearance. It now represents a bridge between quality and sustainability — showing that recycled materials can meet the same visual standards as virgin plastics when handled with care and technical know-how.

The Importance of Color in a Sustainable World

Color is not a minor detail. It’s part of a brand’s identity. A detergent bottle, a cosmetics jar, or a water pipe — all of these products depend on color consistency to meet customer expectations. A shift of just one or two shades can be seen instantly by the naked eye.

That’s why color control is now one of the most critical aspects of recycled plastic pelletizing.

Recycling changes the polymer base, and this affects how pigments behave during extrusion. A slightly yellow recycled PET or a gray recycled HDPE can completely distort the target color if not carefully corrected.

Here is where red masterbatch and blue masterbatch play their vital roles.

The Role of Red and Blue Masterbatch in Recycled Plastics

Masterbatch is the heart of color control. It is a concentrated mixture of pigments and additives dispersed in a carrier resin. When added to recycled plastic, it provides strong, uniform color and helps correct base tone variations.

Red masterbatch and blue masterbatch are especially valuable because they do more than just color a product — they also balance the color spectrum of recycled materials.

The Technical Challenge: Color Matching on Unstable Bases

One of the hardest parts of recycled plastic production is color matching. With virgin resin, the base color is consistent — you can expect the same results every time. But recycled materials are unpredictable.

Imagine you are running a line of recycled HDPE pellets. The first batch might have a light gray base, while the second is slightly yellow. Even if you use the same red or blue masterbatch formula, the outcome can differ noticeably.

To solve this, many recyclers are now using color measurement systems that evaluate the base polymer before coloring. This allows technicians to adjust masterbatch ratios dynamically. Sometimes just a small percentage shift in blue masterbatch can turn a dull product into a bright, market-ready material.

In some cases, masterbatch suppliers create custom formulations specifically for recycled streams. They test multiple pigment combinations to ensure thermal stability, good dispersion, and resistance to fading.

This cooperation between recyclers and color experts has become an essential part of quality control.

Case Study: Adding Value with Red Masterbatch

In East Africa, another manufacturer faced a similar challenge but with a very different application. They were making recycled PP chairs and crates. The color was inconsistent — mostly faded and uneven.

After working with a masterbatch supplier, they switched to a red masterbatch with higher pigment loading and better dispersion. The results surprised everyone: the surface gloss improved, and the red tone became richer and more uniform.

These improvements allowed the factory to move from low-end to mid-market products, increasing their profit margin. It also proved that recycled materials can be used in high-appearance applications if the right coloring technology is applied.

Beyond Color – The Role of Additives

Color masterbatches often include more than pigments. In recycled plastics, it is common to add stabilizers, antioxidants, or process aids to improve material performance.

For example, a blue masterbatch may contain optical brighteners that enhance brightness and hide slight contamination. A red masterbatch can include heat stabilizers that protect color tone during extrusion.

These small modifications help manufacturers overcome the natural variability of recycled materials.

The New Standard of “Good Recycled Plastic”

In the early days of recycling, “good quality” simply meant material that didn’t clog filters. Now, expectations are much higher.

A good recycled pellet must:

Have consistent color and gloss.

Maintain stable melt flow rate.

Process easily without odor or degradation.

Meet appearance standards of brand owners.

Color masterbatch technology supports all four of these requirements. It’s no longer just about aesthetics — it’s a fundamental part of material engineering.

Collaboration: The Key to Quality Stability

The best results in recycled plastics come when recyclers, compounders, and masterbatch suppliers work closely together. The recycler provides the base resin, the masterbatch supplier provides the color expertise, and the compounder ensures the final product meets specifications.

This three-way collaboration allows faster color adjustment and more stable quality control. Many leading recyclers now run joint projects with color laboratories to develop formulations tailored to their specific waste streams.

For example, a recycler handling mostly blue-tinted bottles may use a different blue masterbatch formulation than one using mixed-color waste. These fine adjustments make a big difference at industrial scale.

Market Trends and Regional Insights

The global market for recycled plastic pellets continues to expand at an estimated rate of 7–8% per year. Asia and Africa are leading the growth due to increasing industrialization and rising awareness of sustainability.

Packaging, film, and household goods are the top segments driving demand. In each of these sectors, color quality remains a top concern.

Red and blue tones dominate because they are widely used in branding and consumer packaging. For example:

Blue is associated with purity, water, and trust — ideal for bottles and containers.

Red suggests energy and visibility — perfect for logos and promotional products.

The ability to reproduce these tones accurately in recycled plastics has become a competitive advantage.

My Perspective: The Future Depends on Color Control

As someone who observes this industry closely, I believe that color control will define the next stage of recycling success. Many factories already have good equipment and raw material sources. What separates the leaders from the rest is their ability to deliver stable, repeatable results.

Color consistency builds customer trust. A buyer who knows every batch will match the previous one is more likely to sign long-term contracts.

And that’s where red masterbatch and blue masterbatch play a symbolic role. They represent not only the color of the product but also the confidence behind it — a sign that recycled plastics can meet high visual and technical standards.

Challenges Ahead

Despite the progress, challenges remain.

Contamination from mixed waste still causes discoloration.

Limited access to high-quality pigments affects performance.

Price pressure sometimes forces producers to use cheaper, unstable masterbatches.

To overcome these issues, the industry needs more technical training, better communication between suppliers and users, and stronger testing systems.

Sustainability should not mean lower quality — it should mean smarter production.

A Step Toward a Circular Future

Recycled plastic pelletizing will continue to expand. But growth alone is not enough. The focus must shift toward quality stability. The use of precise, high-performance color masterbatch — especially red and blue formulations — will remain a cornerstone of this progress.

When recycled plastics can achieve both environmental and aesthetic standards, the circle of sustainability becomes complete.