South African Client Praises Our Masterbatch Solutions

In global trade, feedback from customers matters more than any brochure or technical sheet. Recently, a South African customer gave strong recognition to our plastic masterbatch after testing it in their production. Their positive feedback is another milestone in our journey as a trusted supplier in the plastics industry.

Customer Background

The customer is based in South Africa and produces packaging films and injection molded products. They reached out to us looking for a reliable masterbatch supplier. Their main goal was clear: improve product quality while keeping costs under control. They had tried other suppliers but struggled with consistency in color and stability during production.

Factory Visit and Inspection

To build confidence, the client visited our factory. What did they see? Large-scale production, modern twin-screw extrusion lines, and strict quality control systems. They walked through our labs and watched how every batch is tested before shipping. They spoke with our engineers and asked detailed questions about raw materials and process monitoring. By the end of the visit, they told us they were impressed. They said the factory scale, cleanliness, and professional testing systems were exactly what they wanted to see in a long-term partner.

Sample Testing

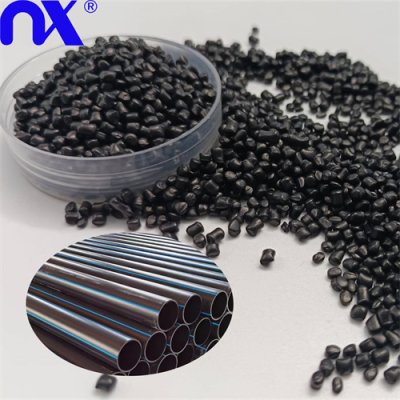

After the visit, we shipped several samples to South Africa. These included black masterbatch, white masterbatch, and calcium carbonate filler masterbatch. The samples were tested in film blowing and injection molding. The focus was on three things: color consistency, processing stability, and final product performance. The results? The customer reported higher transparency in films, stable extrusion, and no clogging issues. In injection molding, they said parts came out with smooth surfaces and strong color strength.

Customer Feedback

The client’s words were encouraging. They said, “Your masterbatch gave us better results than the previous supplier. Our films look clearer, and our molded parts are more uniform.” They also mentioned fewer production interruptions, which helped reduce waste and save costs. For them, this was not just about color but about overall production efficiency. Their management team confirmed they plan to continue using our products for future projects.

Continuous Improvement

We do not see customer feedback as the end of the story. Instead, we see it as the starting point for further improvement. Each time a client shares their experience, we analyze the results, check technical data, and look for ways to make the product even better. For example, based on the South African client’s suggestions, we are now developing grades with faster dispersion for thin-film applications. We believe that listening to real user feedback is the best way to grow together with customers.

Our Product Advantages

Stable quality thanks to strict production control.

High color strength with excellent dispersion.

Dust-free pellets that are easy to feed and mix.

Strong UV resistance for outdoor products.

Compatibility with PE, PP, and other base resins.

From my perspective, these strengths are not just technical points. They directly impact customers. Less waste, fewer complaints, and more competitive products. That is why masterbatch is more than a colorant—it is a tool for business growth.

Technical Parameters

To give pipe manufacturers, film makers, and injection molders a clearer idea, here are typical parameters of our masterbatch products. These numbers can be adjusted for customized grades.

| Property | Black Masterbatch | White Masterbatch |

|---|---|---|

| Main Pigment | Carbon Black | Titanium Dioxide (TiO₂) |

| Pigment Content | 20% – 50% | 40% – 75% |

| Carrier Resin | PE / PP | PE / PP |

| Moisture Content | ≤ 0.15% | ≤ 0.15% |

| Density | 1.2 – 1.5 g/cm³ | 1.3 – 1.6 g/cm³ |

| Melt Flow Index | 5 – 20 g/10 min (190°C/2.16kg) | 8 – 25 g/10 min (190°C/2.16kg) |

| Applications | Pipes, Films, Injection Molding, Cables | Films, Packaging, Fibers, Injection Molding |

| Special Features | UV Protection, Strong Dispersion, High Color Strength | High Brightness, Gloss, Opacity |

Market Outlook

South Africa is a growing market for plastics. Demand for packaging films, pipes, and molded products is increasing. Local producers are searching for stable suppliers who can provide not just material but also technical support. Our factory is ready to fill this role. With more than 10 years of experience, a strong R&D team, and global supply capacity, we aim to serve not only South Africa but also neighboring markets in Africa.

Looking Ahead

This case is a clear example of how strong partnerships can be built. From factory visits to sample testing, to positive feedback—it is a journey of trust. For us, the South African customer is not just a buyer. They are a partner. We look forward to more joint projects, new product development, and continuous improvement. Together we can explore opportunities in packaging, infrastructure, and recycling applications.

Conclusion

The recognition from the South African customer is both an honor and a responsibility. It motivates us to keep improving. It shows that quality, service, and customer feedback matter in today’s plastics industry. With each positive case, we move one step closer to our goal: to be a trusted and innovative supplier of masterbatch solutions worldwide.